Originally intended as a replacement for traditional wiring harnesses, flexible printed circuits have grown exponentially since the early days of World War II. Flexible circuits have excellent versatility, ideal for simple to complex applications, and can handle almost any circuit board job.

What is a flexible printed circuit?

Flexible printed circuits are lightweight circuits that easily fit into small Spaces and contoured shapes. But they're not just bent PCBS. Flexible circuits have unique differences and advantages that require unique designs by innovative PCB manufacturers.

Flexible printed circuit boards consist of conductive metal strips, usually made of copper, and are insulated by dielectric materials or solder resistance layers. The key function of the circuit board is to provide mechanical bending while transmitting electrical signals, enabling the use of smaller connectors and shielding EMI from radiated noise.

A PCB is a substrate or non-conductive board used to connect electronic components to form a circuit.

Basic types of flexible printed circuits

The variety of available configurations, sizes and features highlight the versatility of flexible boards. The basic types of flexible circuits include single - sided circuits, double - sided circuits and multilayer circuits.

unilateral

Single-sided PCB circuits have only a single layer of metal on one side of the dielectric layer.

Two sides

In contrast, double-sided wiring has a metal layer on either side of a single dielectric layer.

Multilayer

In double-sided circuits, metal layers are often connected by metallizing through holes. The same through-hole can be found on a multilayer board containing several separate copper layers encapsulated by a dielectric layer.

Rigid and flexible

A rigid flexible PCB combines elements from both hard and flexible circuits to form a hybrid electric subgrade board.

Benefits of flexible printed circuits

Flexible electronics have several advantages over traditional rigid plates and cables. These include more precise wiring, elimination of mechanical connectors, complete design flexibility, higher circuit density, wider operating temperature range, stronger signal quality, improved impedance control and reliability and size reduction.

Automated production eliminates human errors common in manual wiring harnesses. The flexible circuit can only reach the point indicated in the design plan. In the process of custom PCB printing involves less labor, flexible PCB production cost is high and save time.

Since the degree of freedom of the design process is not limited by two dimensions, the flexible circuit board can be customized in various ways. This flexibility extends to installation, allowing the third dimension of the channel to be connected between two or more planes.

The functionality of the flexible circuit board is improved by increasing airflow, heat dissipation and the application of high-density devices in point-to-point connections using simplified circuit geometry.

Infrastructure application

Before designing a circuit, two basic structural applications will determine the choice of conductors. A static application is one that requires only flexible circuitry for flexible installation. This application typically uses electrodeposited (ED) copper, which is a less expensive option.

Dynamic flexure applications involve dynamic flexure of flexible circuits during the daily use of products. Clamshell phones, laptops and computer arms all require rolling (RA) copper active applications.

Flexible printed circuit functions

Single - and double-sided flexible circuits can have reverse bars, through holes, floating fingers, and ZIF terminations. Multilayer flexible PCBS can contain up to 20 layers and handle high circuit density with multiple conductive layers, through-hole components, embedded resistors, controllable impedance, and EMI shielding.

When the through-hole diameter needs to be minimized, FPCB uses minimal spacing and component size to improve signal integrity, electrical performance and thermal performance.

Flexible designs also allow the same high-density components to be used in rigid PCBS by using blind or buried holes to draw signal wires out of high-density areas of the device. Controllable impedance is significantly improved by fast signal switching, fast conversion and high clock rate. Signal transmission in all PCBS requires laminates of uniform thickness and electrical signals.

Thin films provide protective shielding that reduces noise and controls the impedance of signal lines, while stiffener plates enhance flexible circuits where components require durability and mounting support.

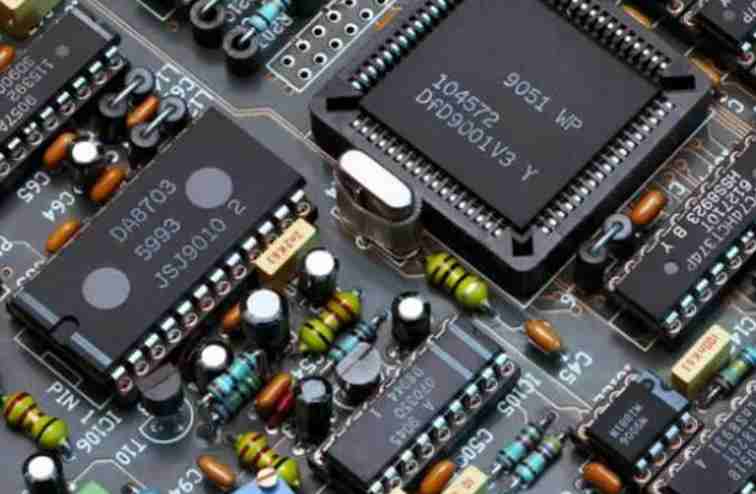

Flexible printed circuit board materials

Flexible printed circuit boards are made of materials similar to other PCBS. All circuits require metal conductors to power them, and copper is the most commonly used material in PCBS. Copper comes in a variety of thicknesses to suit different tastes. Other conductor options include aluminum, silver ink, carbon, and Constantine.

Adhesive holds the layers of a printed circuit board together. The specific material depends on the user and conductor thickness requirements, but all bonds must remain strong within the operating temperature range. Standard binders used in flexible PCBS include epoxy, acrylic or pressure sensitive binders.

Insulators encapsulate and separate circuits with flexible substrates and covering materials. Polyamides, polyesters, solder resistance films and dielectric materials often act as insulators for flexible printed circuit boards.

Complete PCBS have a finishing touch at the end of the assembly process and can be customized according to consumer preferences and circuit functions. Standard finishes applied to the final product include solder, tin, nickel, gold, silver or carbon.

But are printed circuit boards toxic? Burning the plastics and metals in PCBS releases toxins such as furans and dioxins, which means circuit boards in landfills can end up contaminating groundwater if not properly recycled.

However, you can quickly repair a damaged PCB to restore its original function or recycle it in a completely different device.

Advanced function

Flexible circuit boards have come a long way since their invention. As the market for flexible PCBS has expanded, advances in technology have allowed advanced features to be included in circuit designs. Advanced features include a radiator for radiating heat away from sensitive areas and additional components for expandable mounting and protection functions.

As the speed of signal switching increases, better impedance control is required. Advanced impedance wiring minimizes electrical reflection to prevent errors during transitions between interconnects and to control the cable when optimized.

Other features are also available, including crimping pins, graphic overlays, laser cut grooves, carved flexible circuits, shields, flexible heaters and stiffeners. With so many possibilities, there is a flexible circuit board to suit every need.