What is a pcb circuit board? How much do you know about the composition of PCB circuit board?

The computer has the computer circuit board, the machine has the machine circuit board, a lot of electronic products are required to be equipped with the corresponding circuit board. pcb circuit board is also a kind of electronic products, I believe that a large number of friends do not know what kind of product this is, this also has doubts. So what exactly is a pcb board? What are the components of the pcb circuit board? Next, let's take a look at some of the responses from our friends.

What is a pcb circuit board?

PCB, Chinese name called printed circuit board, is the support body of electronic components, is the electrical connection provider of electronic components. According to the circuit layer number can be divided into single panel, double panel and multi - layer board. Common multilayer board is generally 4 or 6 layers, complex multilayer board can reach more than a dozen layers. While China has become a major manufacturer of electronic products, global PCB production capacity is also transferring to China.

Not only domestic PCB manufacturing enterprises accelerate to expand production capacity, but also foreign enterprises accelerate to transfer and increase production capacity to China, and domestic PCB industry investment is always hot. The most important driving force for the achievement of China's PCB industrial power is cost and application industry chain. In terms of cost advantage, China has huge advantages in labor, land, hydropower, resources and policies. The booming downstream industry in China, the global complete machine manufacturing transfer to China, provides a huge market demand space. Due to the concentration of downstream industries and the relatively low cost of labor and land, China has become the region with the strongest development momentum. Printed circuit board, also known as printed circuit board, printed circuit board, short for printed board, English short for PCB, with insulation board as the base material, cut into a certain size, it is attached with at least one conductive graphic, and cloth holes (such as component holes, fastening holes, metallized holes, etc.), used to replace the chassis of the previous device electronic components, and realize the mutual connection between electronic components. Because the board is produced by electronic printing, it is called "printed" circuit board.

The customary term "printed circuit board" as "printed circuit" is incorrect because there are no "printed components" on a printed board, only wiring. Keyou Circuit Technology Co., Ltd. was founded in 2003, is committed to PCB proofing and mass production, with high precision single side/double side/multilayer circuit board (1-26 layers), thermoelectric separation copper substrate, multilayer industrial circuit board, power pcb board, medical circuit board, security PCB board, communication PCb board, automotive circuit board, instrument circuit board, Military circuit board, composite bus copper substrate, foldable metal substrate, FPC soft and hard combined board, quality assurance, delivery on time, to sales as one of the high-tech enterprises.

How much do you know about the composition of PCB circuit board?

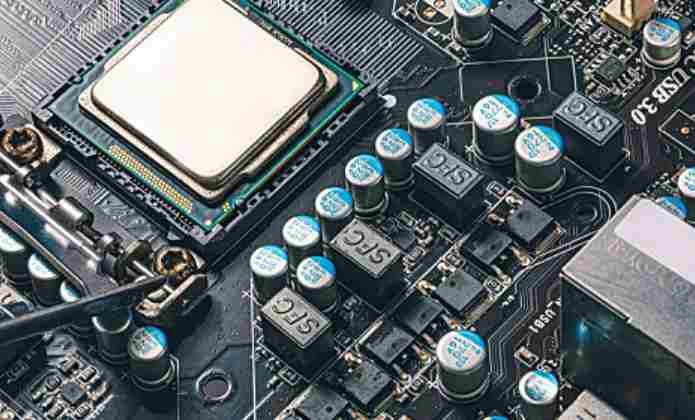

1. Circuit and Pattern: Circuit is used as a tool for conduction between originals. In the design, large copper surface will be designed as the grounding and power layer. The lines and drawings are made at the same time.

2. Dielectric layer: They will be used to maintain insulation between the line and each layer, commonly known as the substrate.

3. Through hole/via: Through hole can make two or more levels of the line through each other, the larger through hole is used as part plug-in, in addition to the non-through hole (nPTH) is usually used as surface mounting positioning, assembly for fixing screws.

4. Solder resistant ink (Solder resistant /Solder Mask) : Not all the copper surface needs to eat the parts on the tin. Therefore, a layer of material (usually epoxy resin) that prevents the copper surface from eating the tin will be printed in the non-solder area to avoid short circuit between the non-solder lines.

5. According to different processes, it can be divided into green oil, red oil and blue oil.

6. . Legend /Marking/Silk screen: This is not necessary, and its main function is to mark the name and position frame of each part on the circuit board for convenient maintenance and identification after assembly.

7. Surface Finish: Because the copper surface is easily oxidized in the general environment, it can not be tinned (poor soldering), so it will be protected on the copper surface to eat tin. Protection methods include Tin spray (HASL), gold (ENIG), Silver (Immersion Silver), tin (Immersion tin), organic flux (OSP), methods have advantages and disadvantages, collectively known as surface treatment.