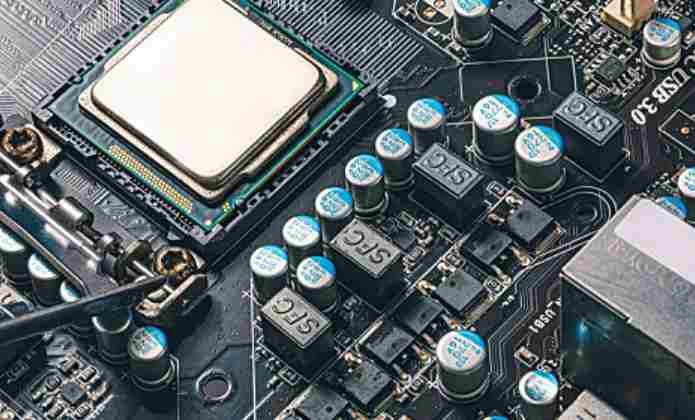

PCB board is printed circuit board, also known as printed circuit board, is the electrical connection provider of electronic components. The following Xiaobian to introduce the PCB board.

Printed circuit board, also known as printed circuit board, printed circuit board, shortened to build and circuit board, often use English (PCB Printed circuit board) or write PWB (Printed wire board), printed with insulation board as the base material, cut to a certain size, with at least one conductive graphic, And distributed holes (such as component holes, fastening holes, metallization holes, etc.), used to replace the chassis of the previous device electronic components, and realize the mutual connection between electronic components. Because the board is produced by electronic printing, it is called "printed" circuit board. According to the number of layers of the circuit board can be divided into single panel, double panel, four layer board, six layer board and other multilayer circuit boards. Keyou Circuit Technology Co., Ltd. is committed to PCB rapid proofing and mass production, with high precision single side/double side/multilayer circuit board (1-26 layers), thermoelectric separation copper substrate, multilayer industrial circuit board, power pcb board, medical circuit board, security PCB board, communication PCB board, automotive circuit board, instrument circuit board, military circuit board, Composite bus copper substrate, foldable metal substrate, FPC soft and hard combined board, quality assurance, delivery on time, to sales as one of the high-tech enterprises.

Printed circuit board, also known as printed circuit board, printed circuit board, shortened to build and circuit board, often use English (PCB Printed circuit board) or write PWB (Printed wire board), printed with insulation board as the base material, cut to a certain size, with at least one conductive graphic, And distributed holes (such as component holes, fastening holes, metallization holes, etc.), used to replace the chassis of the previous device electronic components, and realize the mutual connection between electronic components. Because the board is produced by electronic printing, it is called "printed" circuit board. According to the number of layers of the circuit board can be divided into single panel, double panel, four layer board, six layer board and other multilayer circuit boards. Keyou Circuit Technology Co., Ltd. is committed to PCB rapid proofing and mass production, with high precision single side/double side/multilayer circuit board (1-26 layers), thermoelectric separation copper substrate, multilayer industrial circuit board, power pcb board, medical circuit board, security PCB board, communication PCB board, automotive circuit board, instrument circuit board, military circuit board, Composite bus copper substrate, foldable metal substrate, FPC soft and hard combined board, quality assurance, delivery on time, to sales as one of the high-tech enterprises.

Because the printed circuit board is not a general terminal product, so in the name of the definition is slightly confused, for example: personal computer with the mother board, called the motherboard, but not directly called the circuit board, although there is a circuit board in the host board, but not the same, so the evaluation of the industry about the two can not say the same. Another example: because there are integrated circuit parts on the circuit board, so the news media called it IC board, but it is not the same as printed circuit board. What we usually refer to as a printed circuit board is a bare board - a circuit board with no components on it.

Printed pcb circuit board metal surface preparation technology

In order to meet today's demanding technical standards, the printed circuit board surface condition is a very critical factor. As a result, manufacturers in various countries spend a great deal of time and money in adjusting the surface condition of the metal by means of deburring, cleaning, brushing and grinding. Keyou circuit is and a committed to PCB rapid proofing mass production, with high precision single side/double side/multilayer circuit board (1-26 layers), thermoelectric separation copper substrate, multilayer industrial circuit board, power pcb board, medical circuit board, security PCB board, communication PCB board, automotive circuit board, instrument circuit board, composite bus copper substrate, FPC soft and hard combined board, quality assurance, delivery on time, to sales as one of the high-tech enterprises. Of all the materials for surface adjustment, non-woven products work best. When non-braided materials are used for various polishing, brushing and deburring, it has the advantages of high strength, good durability and long service life. The plasticity of the material ADAPTS to the more complex shape of the board. Non-woven materials can give the uniform finish, brush finish and appearance desired by many products. The key to the excellent performance of non - braided material is its springback and fasting structure. This structure allows for cold operation, thus preventing plate warping and surface deformation.

First, the abrasive analysis of the grinding wheel can be divided into six kinds at present:

1. Emery cloth or sandpaper, perhaps the most widely used form of abrasive, it is not only used in metal processing, but also can be used with other aspects (such as plastic surface processing), have a good polishing effect.

2. In the abrasive series, the grinding wheel has the most cutting ability. It is designed for grinding materials. It can quickly cut large defects from the hardest surfaces.

3. Steel wheel, used for the treatment of serious defects on metal surface.

4. Polishing cloth wheel, can cut a small amount of metal, and can provide mirror polishing.

5. Non-braided abrasive is the ideal material for controlling material cutting and surface cleaning. Abrasive particles are bonded to the surface of the synthetic circular column, and are deburred or brushed at different speeds relative to the surface of the plate to achieve the ultimate purpose of pretreatment.