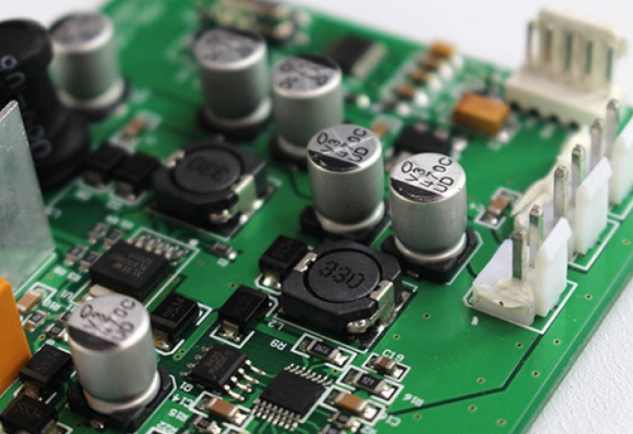

Shenzhen kingford has its own SMT SMT processing plant, which can provide SMT processing services of 0201 components with minimum packaging. The SMT processing capacity is 3 to 4 million points/day, and supports incoming processing and OEM of various PCBA processing forms. Next, we will analyze which SMT processing plant is good?

First, understand the main points of the patch processing plant

1. Professional compatibility

SMT patch processing is a part of the entire process of electronic products. In the case of advanced equipment precision and perfect management, the professional cooperation of SMT patch processing plant seems to determine whether your PCB board can be delivered on schedule, whether the quality can be controlled, and whether it can be repaired in time. These added values are far higher than the unit price gap between 9 percent and 1 percent. How to check the cooperation degree of SMT factory? Start with people. Talk with the management and even the boss of the SMT factory to see if they have a sincere attitude and belief. In addition, the third party can also know the reputation of the processing plant and the customer cases served and so on.

2. Quality management process

Many SMT processing plants in order to reduce the unit price in the market, at the risk of sacrificing quality, reduce QC personnel or do not equip with AOI testing and other means. In the process of evaluating SMT processing plant, it is necessary to observe and understand in detail whether IQC, post-furnace inspection, QC and other series positions are set up in the warehouse, whether AOI inspection equipment is reasonably equipped, whether it is opened and used, and how engineers introduce quality management methods and documents, etc. Only with a comprehensive understanding, can you ensure that your products can be perfectly processed.

3. Mental outlook of management and employees

The mental outlook of front-line employees and managers determines whether your products can maintain a higher yield, consistency, etc., because the products are made by people or operating equipment. Whether the communication with the manager is smooth, whether there is passion, whether the staff work meticulously, each does his job.

2. Give up the surface of these SMT patch processing plants

1. Only look at the scale of the patch factory

Unless your order is sufficient for 100k, any SMT factory can do it.

2. Only look at SMT patch equipment

Unless PCB board has very small material (such as 0201 and below) or complex process (POP, etc.), ordinary factory SMT equipment can be done

3. Only look at offers

At first glance, if the quotation is slightly out of line, we will deny one SMT processing plant, which may be a very good one. Everything dare to open, are capable of quality requirements, the initial offer can only refer to, or even do not refer to.

4. Only look at the salesman's chest

It is very risky to choose this supplier based on chest-thumping promises or happy chat from SMT factory.

3. Why do you choose kingford?

1. Strength guarantee

▪SMT workshop: We have imported SMT machines and several sets of optical inspection equipment, with a daily output of 4 million. Each process is equipped with QC personnel, who can keep an eye on product quality.

▪DIP production line: We have two wave-soldering machines, among which there are more than 10 old employees who have worked for more than three years. The skilled workers can weld all kinds of plug-in materials.

2. Quality assurance, cost-effective

▪ High-end equipment can stick precision shaped parts, BGA, QFN, 0201 materials. Can also template patch, loose material hand.

▪ Sample and size batch can be produced, proofing from 800 yuan, batch 0.008 yuan/point, no start-up fee.

3. Rich experience in SMT and welding of electronic products, stable delivery

▪ Accumulated SMT SMT processing services for thousands of electronic enterprises, involving many kinds of automotive equipment and industrial control motherboard. The products are often exported to Europe and the United States, and the quality can be affirmed by new and old customers.

▪ On time delivery, normal 3-5 days after complete materials, small batch can also be expedited on the same day shipment.

4. Strong maintenance ability and perfect after-sales service

▪ Experienced maintenance engineers can repair all kinds of patch welding caused by bad products, to ensure the connection rate of each piece of circuit board.

▪ 24-hour customer service staff at any time response, the fastest speed to solve your order problems.