How to do PCB reverse development

In the research of PCB reverse technology, reverse derivation schematic diagram refers to deriving the PCB circuit diagram based on the PCB file diagram or directly drawing the PCB circuit diagram according to the actual product, aiming to explain the principle and working condition of the circuit board. Also, this circuit

Diagrams are also used to analyze the functional characteristics of the product itself. In the forward design, the research and development of general products should first carry out the schematic diagram design, and then carry out the PCB design according to the schematic diagram.

Whether it is used to analyze circuit board principles and product operating characteristics in reverse research, or reused as the basis and basis for PCB design in forward design, PCB schematic diagrams have a special role. Then, according to the file diagram or the real object, how to reverse the PCB schematic diagram, and what details should be paid attention to during the reverse derivation process?

1. Reasonable division of functional areas

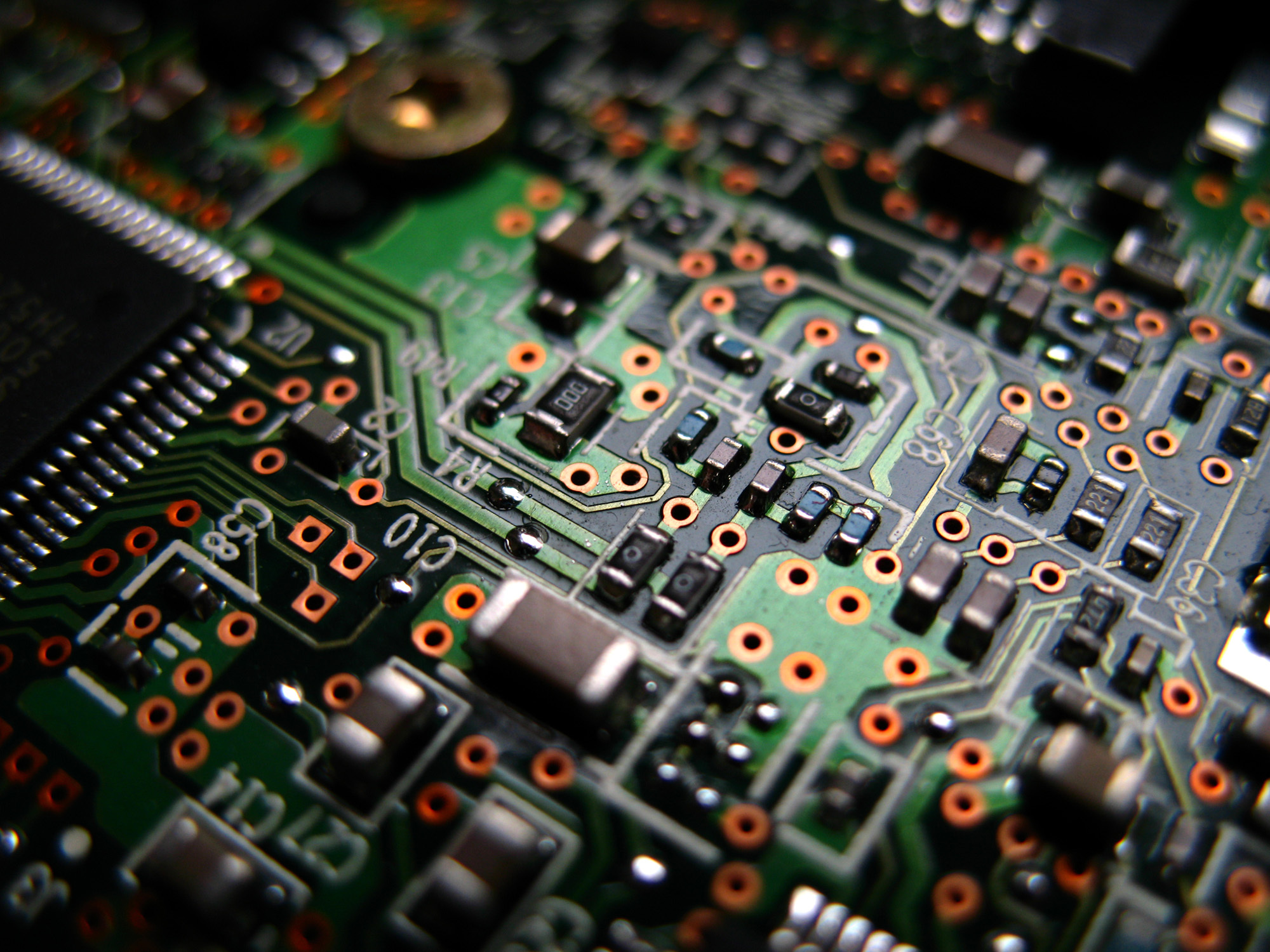

When performing reverse design of a schematic diagram of a complete PCB circuit board, rationally dividing functional areas can help engineers reduce unnecessary troubles and improve drawing efficiency. Generally speaking, components with the same function on a PCB board will be arranged in a centralized manner, and dividing the area by function can provide a convenient and accurate basis for reverse derivation of the schematic diagram.

However, the division of this functional area is not arbitrary. It requires engineers to have a certain understanding of electronic circuit related knowledge. First, find out the core components in a certain functional unit, and then find out other components of the same functional unit according to the wiring connection to form a functional partition. The formation of functional partitions is the basis of schematic diagram drawing. In addition, in this process, don't forget to make good use of the serial numbers of components on the circuit board, which can help you perform functional partitioning faster.

2. Correctly distinguish lines and draw wiring reasonably

For the distinction between ground wires, power wires, and signal wires, engineers also need to have relevant power supply knowledge, circuit connection knowledge, PCB layout knowledge, and so on. The distinction of these lines can be analyzed from the aspects of the connection of components, the width of the copper foil of the line, and the characteristics of the electronic product itself.

In wiring drawing, in order to avoid crossing and crossing of lines, a large number of grounding symbols can be used for ground lines, different lines of different colors can be used for various lines to ensure clear identification, special signs can be used for various components, and even Draw unit circuits separately and combine them at the end.

3. Find the reference parts

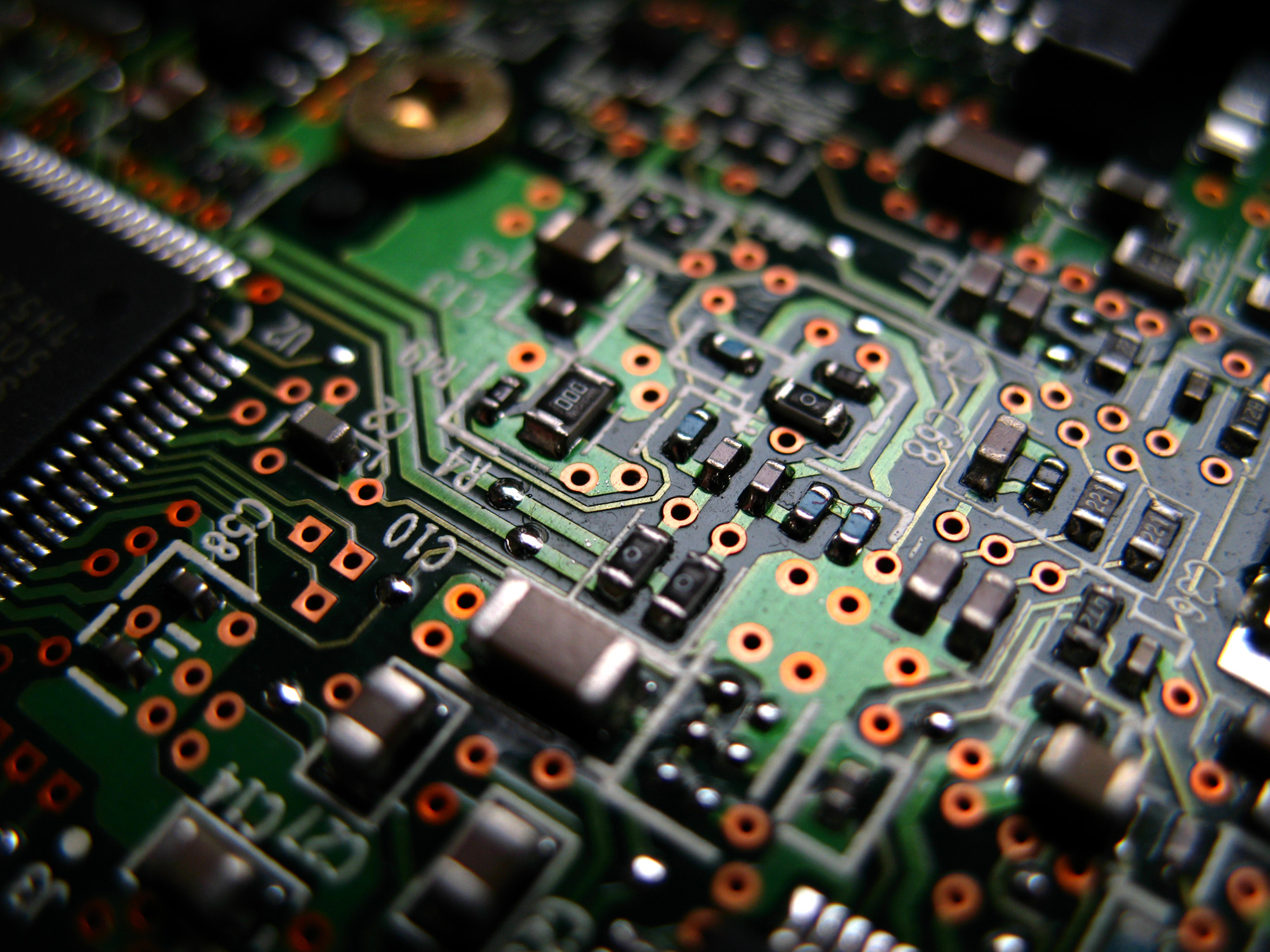

This reference part can also be said to be the main component used at the beginning of drawing the schematic diagram. After the reference part is determined, drawing according to the pins of these reference parts can ensure the accuracy of the schematic diagram to a greater extent.

For engineers, the determination of reference parts is not a very complicated matter. Generally, components that play a major role in the circuit can be selected as reference parts. They are generally larger in size and have more pins, which is convenient for drawing. Such as integrated circuits, transformers, transistors, etc., can be used as suitable reference parts.

4. Master the basic framework and learn from similar schematic diagrams

Engineers need to be proficient in the frame composition and schematic diagram drawing of some basic electronic circuits. Not only must they be able to directly draw the basic composition forms of some simple and classic unit circuits, but they must also be able to form the overall framework of electronic circuits.

On the other hand, don't ignore that the schematic diagrams of the same type of electronic products have a certain similarity. Engineers can use the accumulated experience and fully learn from similar circuit diagrams to reverse the schematic diagrams of new products.

5. Verification and optimization

After the schematic drawing is completed, it is necessary to go through strict testing and verification before the reverse design of the PCB schematic is completed. The nominal value of components sensitive to PCB distribution parameters needs to be checked and optimized. According to the PCB file diagram, the schematic diagram is compared, analyzed and checked to ensure that the schematic diagram is completely consistent with the document diagram, and then the prototype is tested.