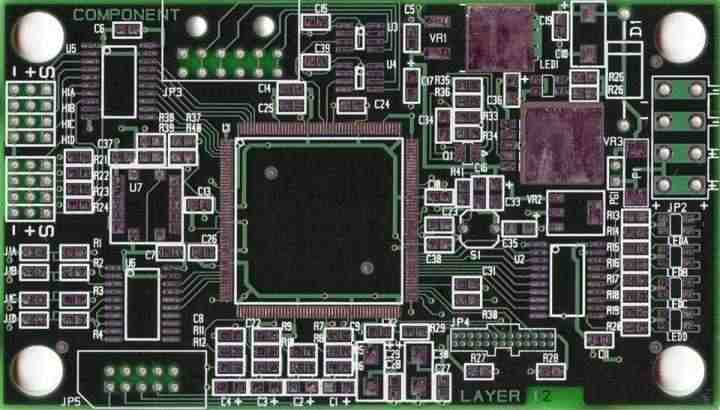

How to make PCB quickly

With the continuous improvement of electronic communication technology, more and more traditional circuit board manufacturing methods have been far from meet the rapid development of this era, want to really fast production of high precision, good perform