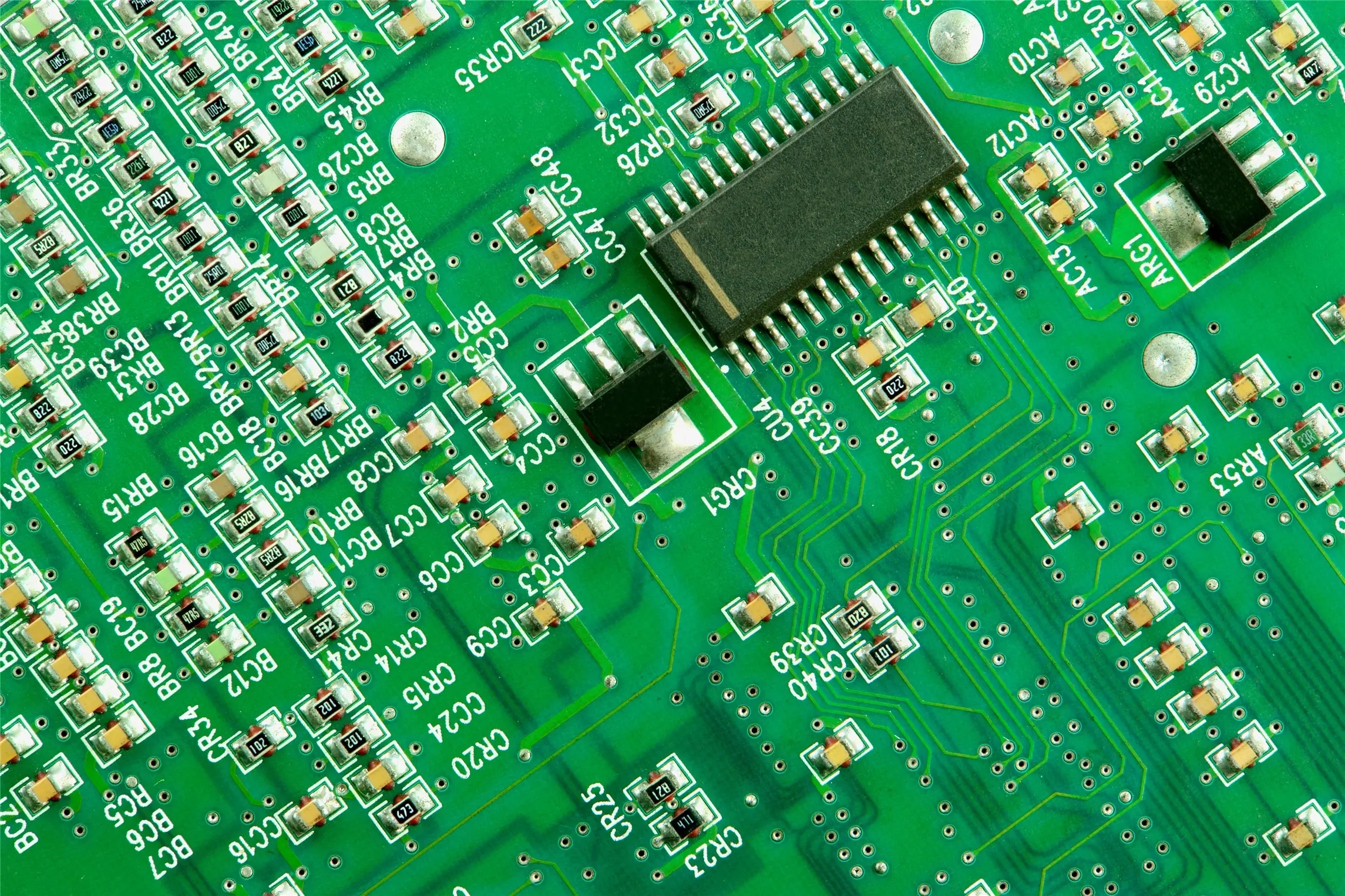

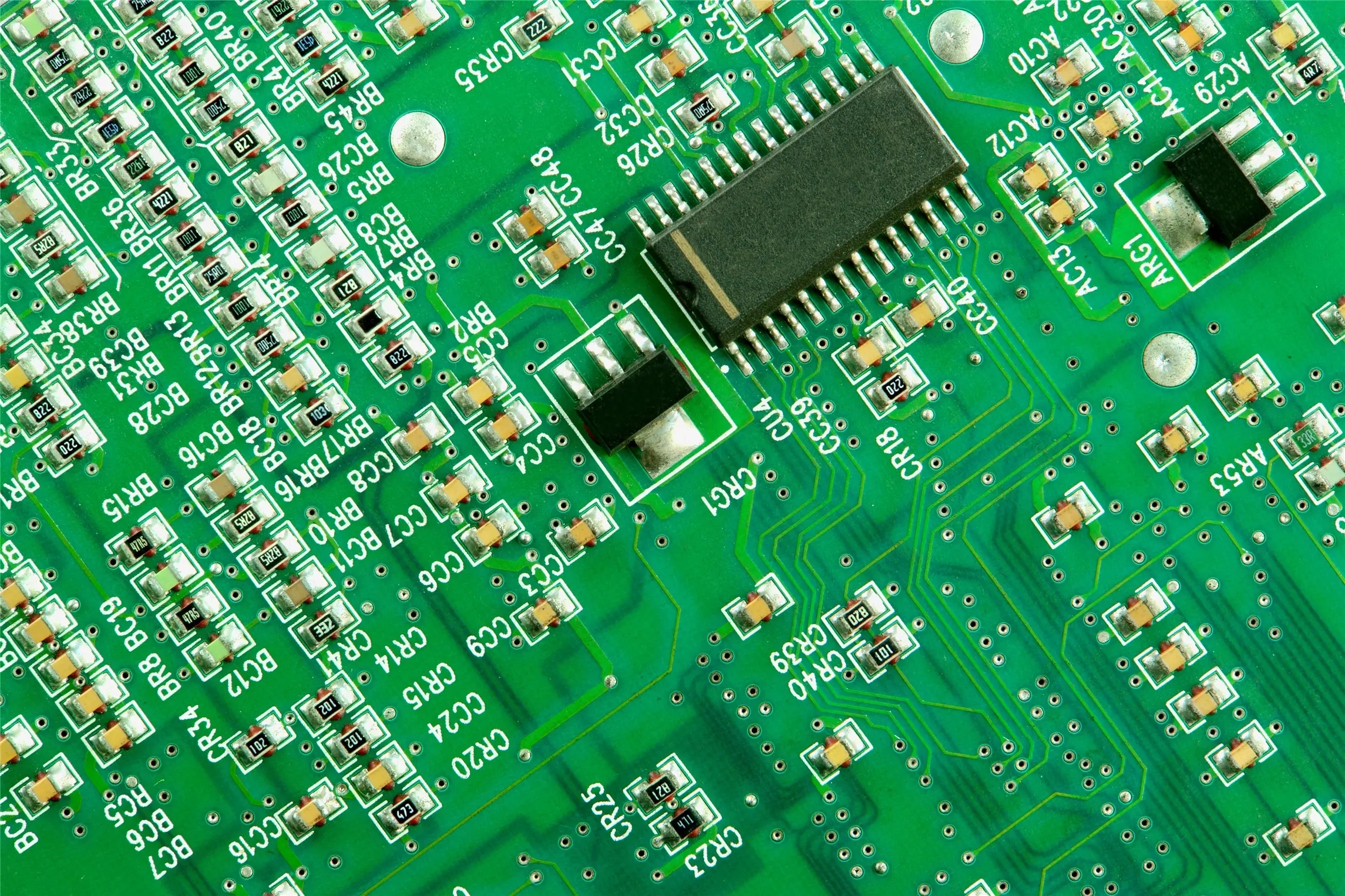

What are the two main aspects of quality control of PCBA processing

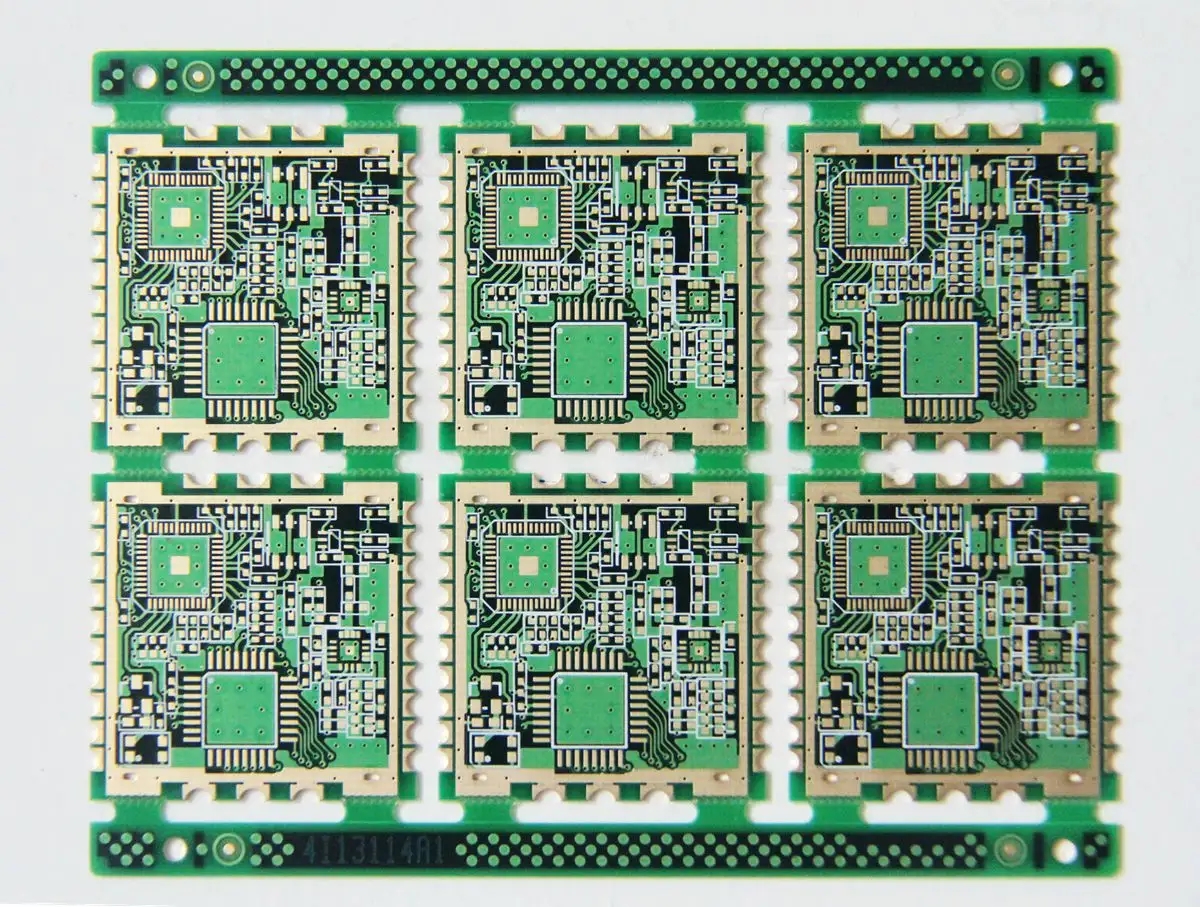

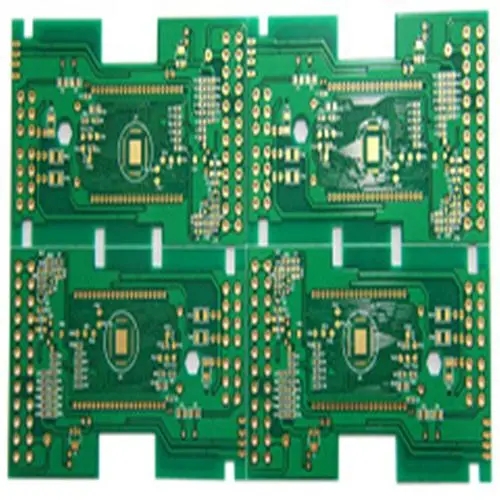

The whole process of PCBA processing includes PCB processing, SMT mounting, component procurement and inspection, DIP plug-in post welding, burning test, aging, assembly and other processes.

The whole process of PCBA processing includes PCB processing, SMT mounting, component procurement and inspection, DIP plug-in post welding, burning test, aging, assembly and other processes. The whole processing process involves a wide range of details, including quality control. If there is no very strICt quality control standard, the inspection standard is not strict or there is no standard to follow, it is very likely that our mistakes in a small link will cause the whole batch of PCBA circuit boards to be scrapped or need to be repaired, thus causing serious quality accidents.

The whole process of PCBA processing includes PCB processing, SMT mounting, component procurement and inspection, DIP plug-in post welding, burning test, aging, assembly and other processes. The whole processing process involves a wide range of details, including quality control. If there is no very strict quality control standard, the inspection standard is not strict or there is no standard to follow, it is very likely that our mistakes in a small link will cause the whole batch of PCBA circuit boards to be scrapped or need to be repaired, thus causing serious quality accidents.

Therefore, in order to summarize a standard test text for the details of quality control, we must understand what aspects and contents are mainly included in the quality control of PCBA processing?

What are the two main aspects of quality control of PCBA processing

1、 PCB

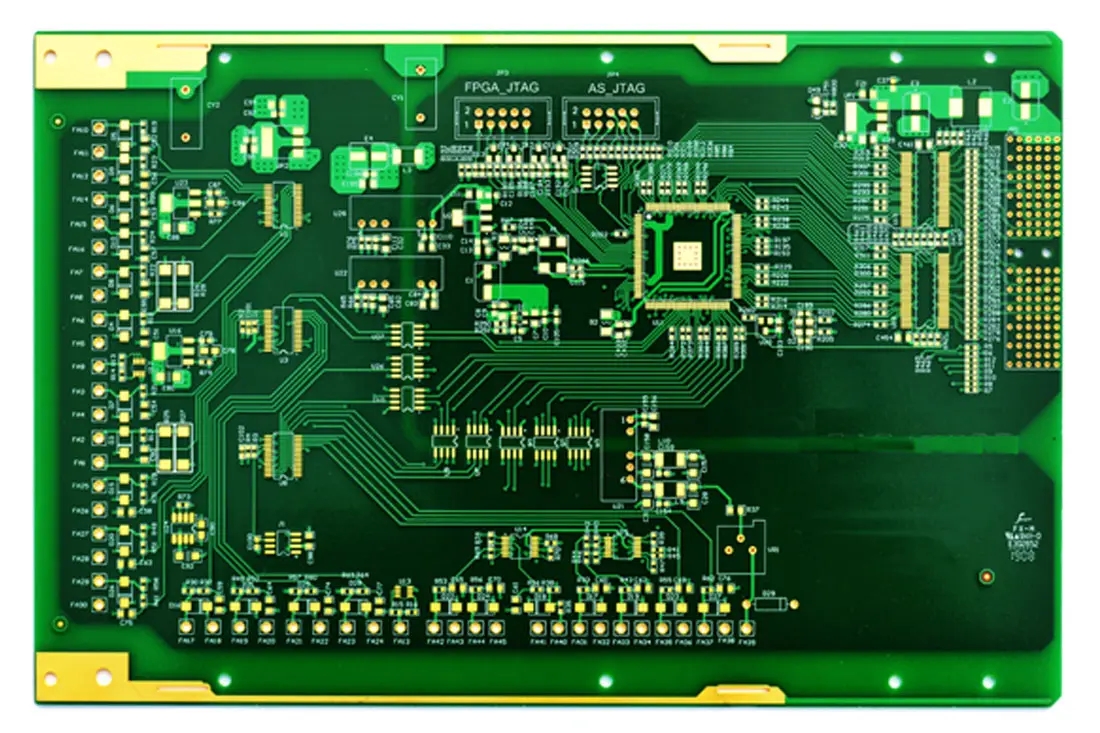

First of all, when we receive the specific needs of customers, we first need the engineering to analyze the process required by customers according to their PCB Gerber documents and PCB manufacturing documents, and at the same time, we need to submit a manufacturability report (DFM) for this process. There are also many small processing plants or even individual companies that are not very strict in quality control and lack of process management, who pay little attention to the manufacturability report. Just blindly take orders to solve problems in production. This seEMIngly time-saving and efficient way is most likely to cause quality problems due to customer PCB design defects. At the same time, it will also cause a lot of rework and repair. Not only the delivery date cannot be met, but also the cost will be increased.

2、 Procurement and inspection of components

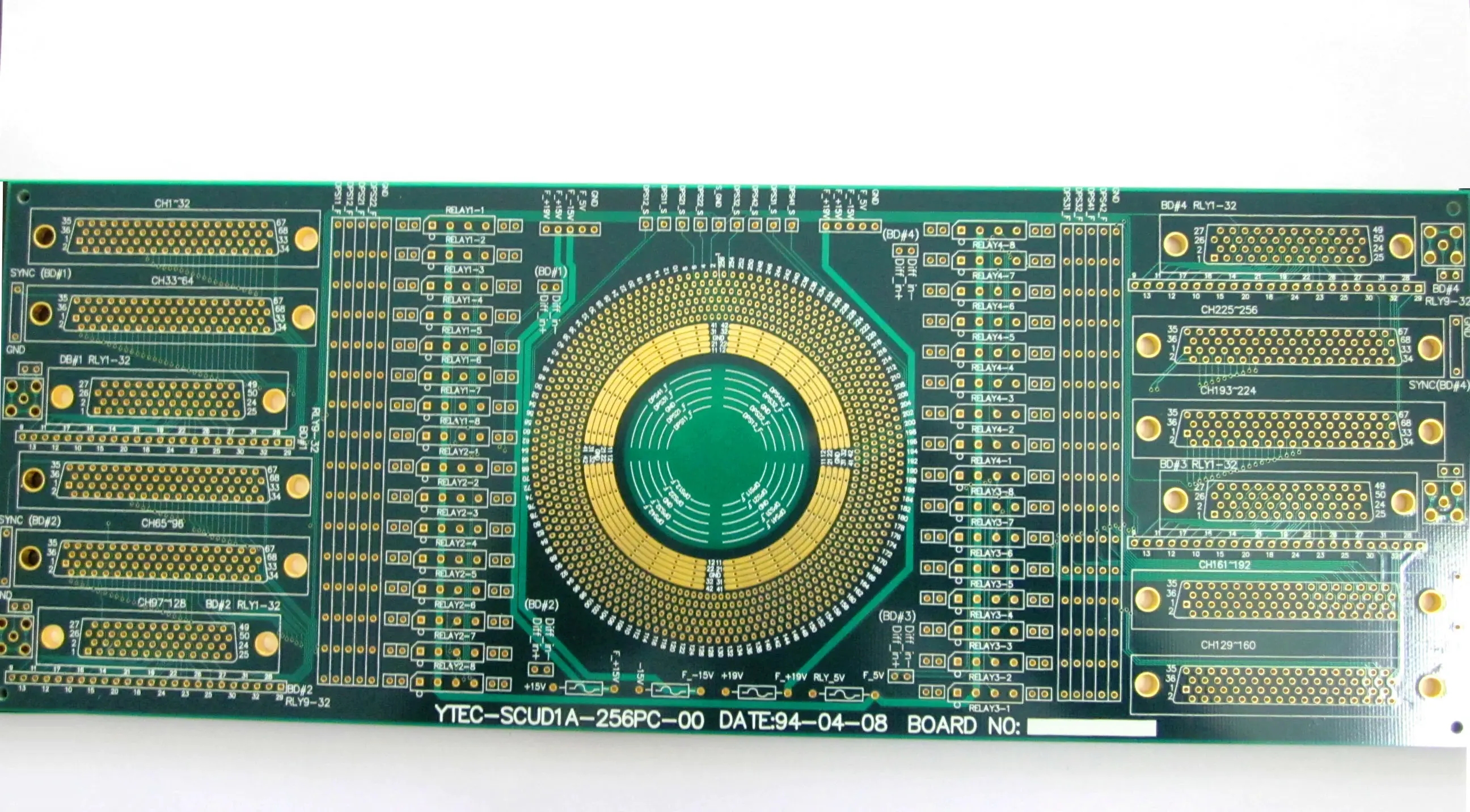

In order to ensure the quality stability and quality of components, it is necessary to strictly control the purchase channels and qualifications of suppliers. Generally, it is designated to take goods from large traders and original manufacturers, so as to avoid the use of second-hand materials and counterfeit materials. In addition, a special PCBA incoming material inspection post shall be set up to strictly inspect the following items to ensure no failure of components.

PCB: check whether the reflow soldering furnace temperature test, no fly wire through hole is blocked or leaked, and whether the board surface is bent.

IC: Check whether screen printing and BOM are identical, and store them at constant temperature and humidity.

Other common materials: check screen printing, appearance, power on measurement, etc.

If there is no problem with PCB and components. We can pay attention to detail control in the whole processing process, and the whole PCBA processing quality can be guaranteed.