Major design of PCB process SMT

Process design

The surface adhesive assembly process, especially for the components with small spacing, requires continuous monitoring of the process and systematIC inspection. For example, in the United States, the quality standard of solder joints is based on IPC-A-620 and the national solder standard ANSI/J-STD-001. Only after understanding these rules and specifications can designers develop products that meet the requirements of industrial standards.

Mass production design

Mass production design includes the manufacturing process, assembly, testability and reliability of all mass production, and it starts from the requirements of written documents. A complete and clear assembly document is an absolutely necessary and successful guarantee for a series of transformations from design to manufacturing. The relevant documents and CAD data list include bill of materials (BOM), list of qualified manufacturers, assembly details, special assembly instructions, PC board manufacturing details and Gerber data or IPC-D-350 program contained in the disk. The CAD data on the disk is of great help to the development of testing and manufacturing tools, and the preparation of automatic assembly equipment programs. It includes the X-Y axis coordinate position, test requirements, outline drawings, circuit diagrams and X-Y coordinates of test points

PC board quality

Take a sample from each batch or a specific batch number to test its solderability. This PC board will first be compared with the quality specification MARKed on the system PC. The next step is to print the solder paste on the solder pad for reflow. If organic flux is used, it needs to be cleaned again to remove the residue. While evaluating the quality of solder joints, we should also evaluate the appearance and size response of PC boards after reflow. The same inspection method can also be applied to the wave soldering process.

Assembly process development

This step includes continuous monitoring of each mechanical action with naked eyes and automatic visual devices. For example, it is recommended to use laser to scan the volume of solder paste printed on each PC board. After the sample is placed on the surface adhesive component (SMD) and re welded, the quality control and engineering personnel shall inspect the tin eating condition on the connector pins of each component one by one, and each member shall record the alignment of the passive component and multi pin component in detail. After the wave soldering process, it is also necessary to carefully inspect the uniformity of soldering tin and determine the potential position that may cause defects in the solder joints due to the close distance between feet or components.

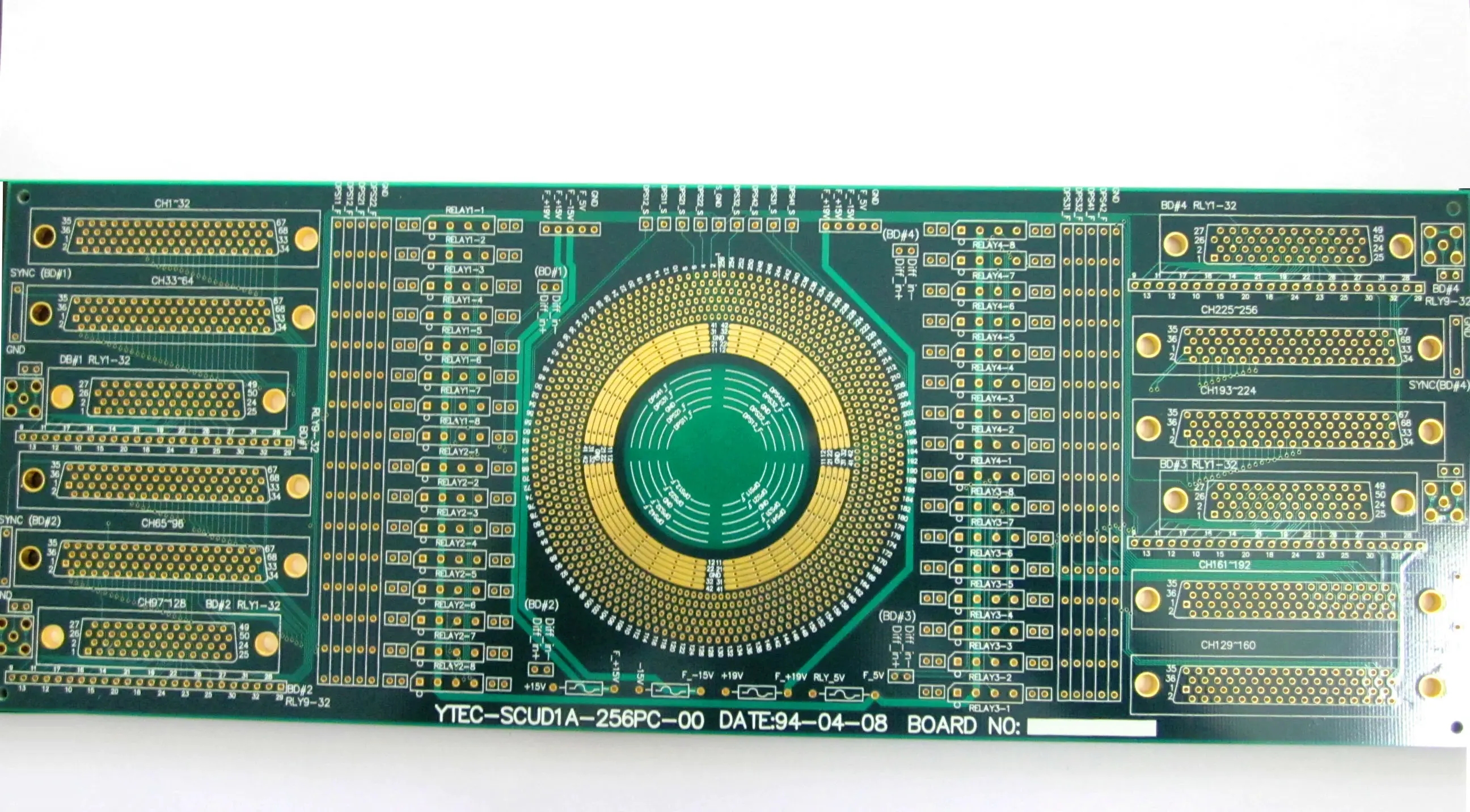

Fine pitch technology

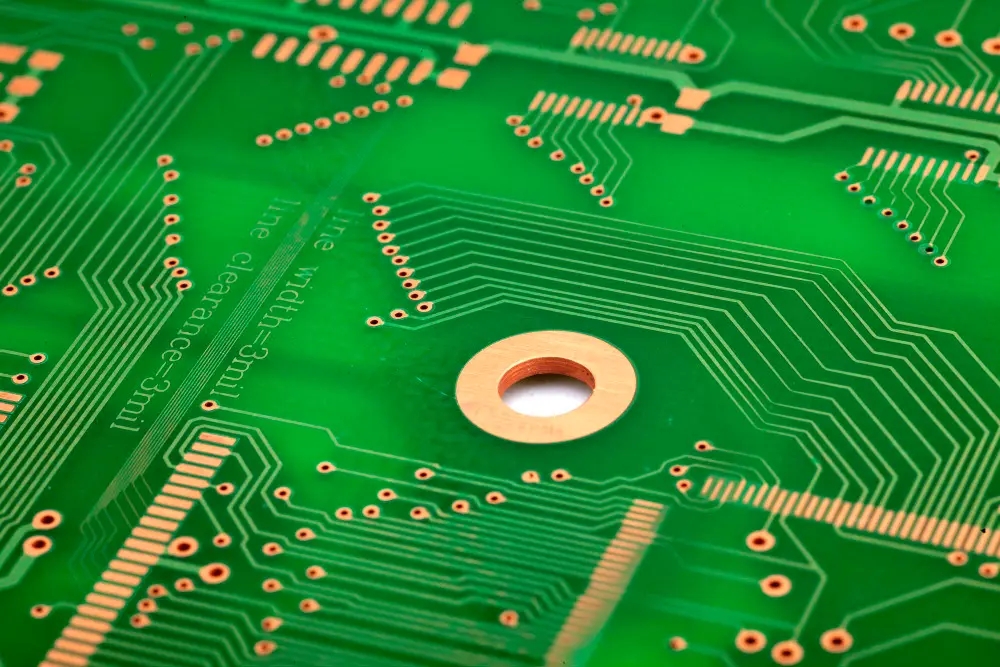

Fine pitch assembly is an advanced construction and manufacturing concept. The density and complexity of components are far greater than the current mainstream products in the market. If you want to enter the mass production stage, you must modify some parameters before putting them into the production line. For example, the foot pitch of fine pitch components is 0.025 "or less, which can be applied to standard and ASIC components. For these components, the industry standard has a very wide tolerance, as shown in Figure 1. Because the tolerance of component suppliers is different from each other, the size of welding pad must be customized for this component, or modified again to truly improve the assembly yield.

The overall dimensions and spacing of welding pads generally follow the specifications of IPC-SM-782A. However, in order to meet the requirements of the manufacturing process, the shape and size of some welding pads will be somewhat different from this specification. For wave soldering tin, the size of the solder pad is usually slightly larger, so as to have more flux and soldering tin. For some components that are usually kept near the upper and lower limits of the process tolerance, it is necessary to adjust the size of the welding pad appropriately.

Consistency of placement orientation of surface adhesive components

Although it is not necessary to design the placement orientation of all components to be the same, for the same type of components, their consistency will help improve the assembly and inspection efficiency. For a complex board, components with pins usually have the same placement orientation to save time. The reason is that the grabs for placing components are usually fixed in one direction, and the plate must be rotated to change the placement direction. For general surface adhesive components, because the gripper of placement machine can rotate freely, there is no such problem. However, if you want to pass the wave soldering furnace, you must unify the orientation of the components to reduce the time they are exposed to the tin flow. The placement direction of some polar components has been determined as early as the whole circuit design. The process engineer can improve the assembly efficiency by determining the placement sequence of components after understanding the circuit functions, but the same orientation or similar components can improve the efficiency. If we can unify the placement orientation, we can not only shorten the speed of writing placement component programs, but also reduce the occurrence of errors.

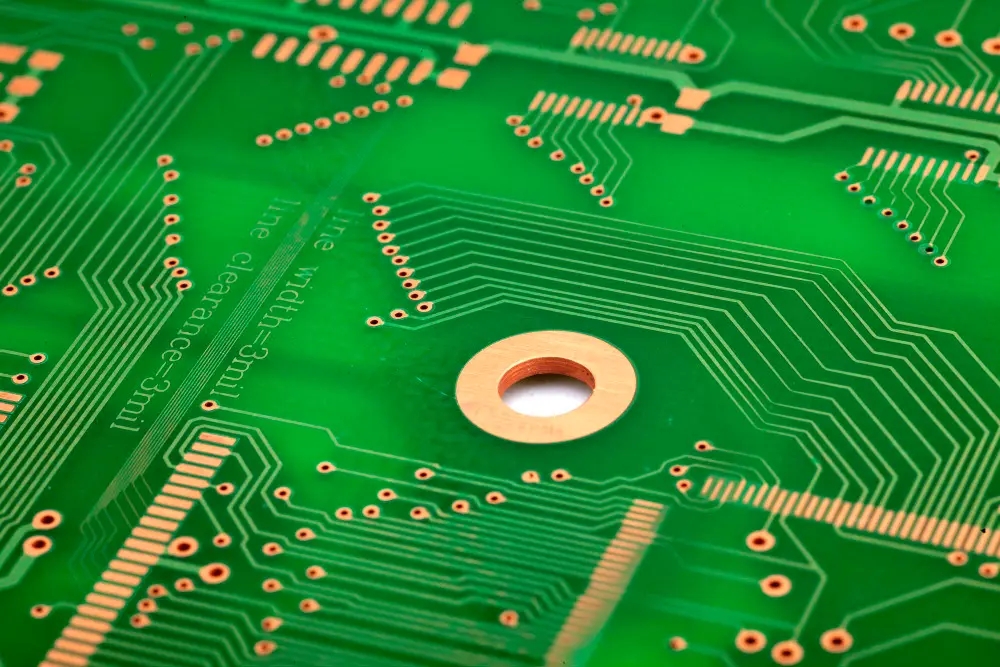

Consistent (and adequate) component distances

The fully automatic surface adhesive component placement machine is generally quite accurate, but designers tend to ignore the complexity of mass production while trying to improve the component density. For example, when a high component is too close to a component with a fine pitch, it will not only block the line of sight for inspecting the solder joints of the pins, but also block the rework or tools used in the rework. Wave soldering is generally used in low and low components such as diodes and transistors. Small components such as SOIC can also be used for wave soldering, but it should be noted that some components cannot withstand direct exposure to the high heat of the tin furnace.

To ensure the consistency of assembly quality, the distance between components must be large enough to be evenly exposed in the tin furnace. To ensure that soldering tin can contact each contact, high components should be kept a certain distance from low and low components to avoid shielding effect. If the distance is not enough, it will also hinder the inspection and rework of components. The industry has developed a set of standards for surface adhesive components. If possible, use standard components as much as possible, so that designers can establish a database of standard weld pad sizes, and engineers can better master the problems in the process. Designers can find that some countries have established similar standards, and the appearance of the components may be similar, but the pin angle of the components may be different due to different countries of production. For example, SOIC component suppliers from North America and Europe can meet EIZ standards, while Japanese products take EIAJ as their design criteria. It should be noted that even if the EIAJ standard is met, the components produced by different companies are not identical in appearance.

Designed to improve productivity

The assembly of PCBA boards can be very simple or very complex, depending on the shape and density of the components. A complex design can make efficient production and reduce the difficulty, but it will also become very difficult if the designer does not pay attention to the details of the manufacturing process. The assembly plan must be considered at the beginning of the design. Generally, the mass production can be increased by adjusting the position and placement orientation of components. If a PC board is small in size, has an irregular shape or has components close to the board edge, it can be considered for mass production in the form of connecting boards.

Assembly process development

This step includes continuous monitoring of each mechanical action with naked eyes and automatic visual devices. For example, it is recommended to use laser to scan the volume of solder paste printed on each PC board. After the sample is placed on the surface adhesive component (SMD) and re welded, the quality control and engineering personnel shall inspect the tin eating condition on the connector pins of each component one by one, and each member shall record the alignment of the passive component and multi pin component in detail. After the wave soldering process, it is also necessary to carefully inspect the uniformity of soldering tin and determine the potential position that may cause defects in the solder joints due to the close distance between feet or components.

Fine pitch technology

Fine pitch assembly is an advanced construction and manufacturing concept. The density and complexity of components are far greater than the current mainstream products in the market. If you want to enter the mass production stage, you must modify some parameters before putting them into the production line. For example, The foot pitch of fine pitch components is 0.025 "or less, which can be applied to standard and ASIC components. For these components, the industrial standard has a very wide tolerance, as shown in Figure 1 As shown in. Because the allowable errors of component suppliers are different from each other, the size of welding pad must be customized for this component or modified again to truly improve the assembly yield. The overall dimensions and spacing of welding pads generally follow the specifications of IPC-SM-782A. However, in order to meet the requirements of the manufacturing process, the shape and size of some welding pads will be somewhat different from this specification. For wave soldering tin, the size of the solder pad is usually slightly larger, so as to have more flux and soldering tin. For some components that are usually kept near the upper and lower limits of the process tolerance, it is necessary to adjust the size of the welding pad appropriately.

Consistency of placement orientation of surface adhesive components

Although it is not necessary to design the placement orientation of all components to be the same, for the same type of components, their consistency will help improve the assembly and inspection efficiency. For a complex board, components with pins usually have the same placement orientation to save time. The reason is that the grabs for placing components are usually fixed in one direction, and the plate must be rotated to change the placement direction. For general surface adhesive components, because the gripper of placement machine can rotate freely, there is no such problem. However, if you want to pass the wave soldering furnace, you must unify the orientation of the components to reduce the time they are exposed to the tin flow. The placement direction of some polar components has been determined as early as the whole circuit design. The process engineer can improve the assembly efficiency by determining the placement sequence of components after understanding the circuit functions, but the same orientation or similar components can improve the efficiency. If we can unify the placement orientation, we can not only shorten the speed of writing placement component programs, but also reduce the occurrence of errors.

Consistent (and adequate) component distances

The fully automatic surface adhesive component placement machine is generally quite accurate, but designers tend to ignore the complexity of mass production while trying to improve the component density. For example, when a high component is too close to a component with a fine pitch, it will not only block the line of sight for inspecting the solder joints of the pins, but also block the rework or tools used in the rework. Wave soldering is generally used in low and low components such as diodes and transistors. Small components such as SOIC can also be used for wave soldering, but it should be noted that some components cannot withstand direct exposure to the high heat of the tin furnace. To ensure the consistency of assembly quality, the distance between components must be large enough to be evenly exposed in the tin furnace. To ensure that soldering tin can contact each contact, high components should be kept a certain distance from low and low components to avoid shielding effect. If the distance is not enough, it will also hinder the inspection and rework of components. The industry has developed a set of standards for surface adhesive components. If possible, use standard components as much as possible, so that designers can establish a database of standard weld pad sizes, and engineers can better master the problems in the process. Designers can find that some countries have established similar standards, and the appearance of the components may be similar, but the pin angle of the components may be different due to different countries of production. For example, SOIC component suppliers from North America and Europe can meet EIZ standards, while Japanese products take EIAJ as their design criteria. It should be noted that even if the EIAJ standard is met, the components produced by different companies are not identical in appearance.

Testing and repair

It is usually inaccurate and time-consuming to use small desktop testing tools to detect missing components or processes, and the testing method must be taken into account in the design. For example, if ICT testing is to be used, it is necessary to consider designing some test points that can be contacted by probes on the line. There is a written program in the test system, which can test the function of each component, point out which component is faulty or placed incorrectly, and judge whether the solder joint is good. The detection error shall also include the short circuit between the component contacts and the empty welding between the pins and the welding pad. If the test probe cannot contact each common junction on the circuit, it is impossible to measure each component individually. Especially for the assembly of micro pitch, it is more necessary to rely on the probe of automatic test equipment to measure the connecting points on all lines or the lines connected between components. If it is not possible to do so, the second best thing is to pass the function test, otherwise the customer will have to wait until the shipment is worn out. ICT test is to make different tools and test procedures according to different products. If the test is considered in the design, the product can easily test the quality of each component and contact.