On line test ICT in PCBA assembly

At present, there are many kinds of testing technologies used in the field of electronic assembly testing, such as Manual Visual Inspection (MVI), In Circuit Tester (ICT), Automatic Optical Inspection (AOI), Automatic X-ray Inspection (AXI), Function Tester (FCT), etc.

They can be classified into two categories according to whether the PCBA board is powered on: one is the electrical testing technology, the other is the end of non electrical testing, and they can also be divided into two categories according to whether the PCBA is in contact with the testing equipment: one is the end of contact testing, and the other is the non-contact testing technology.

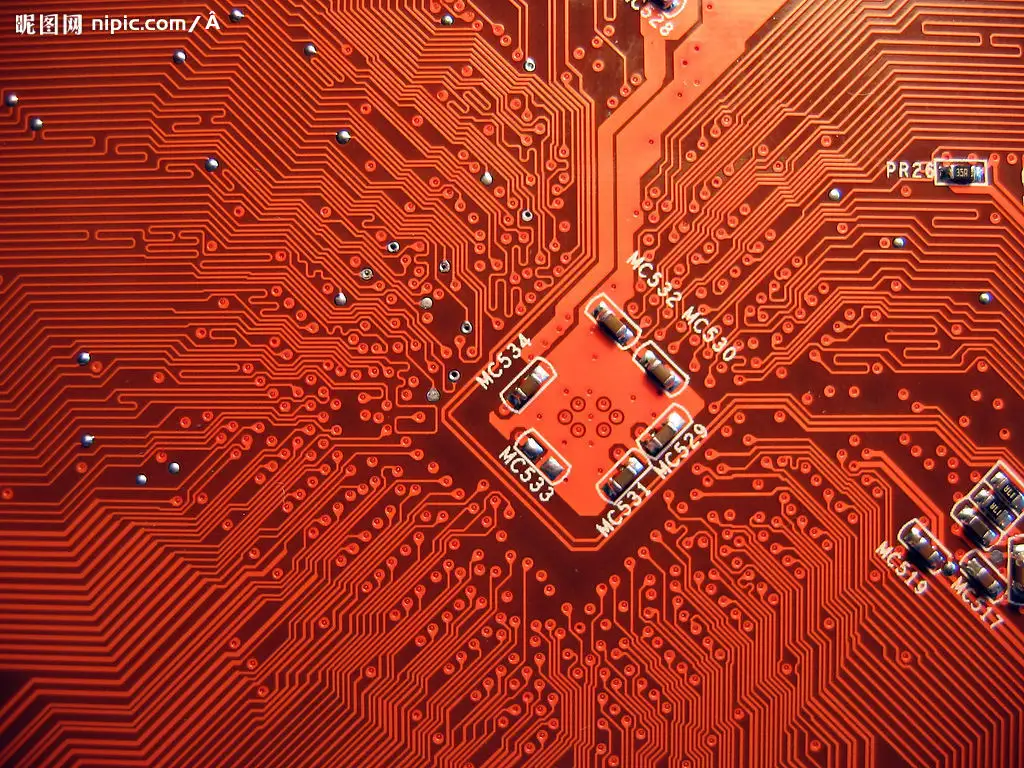

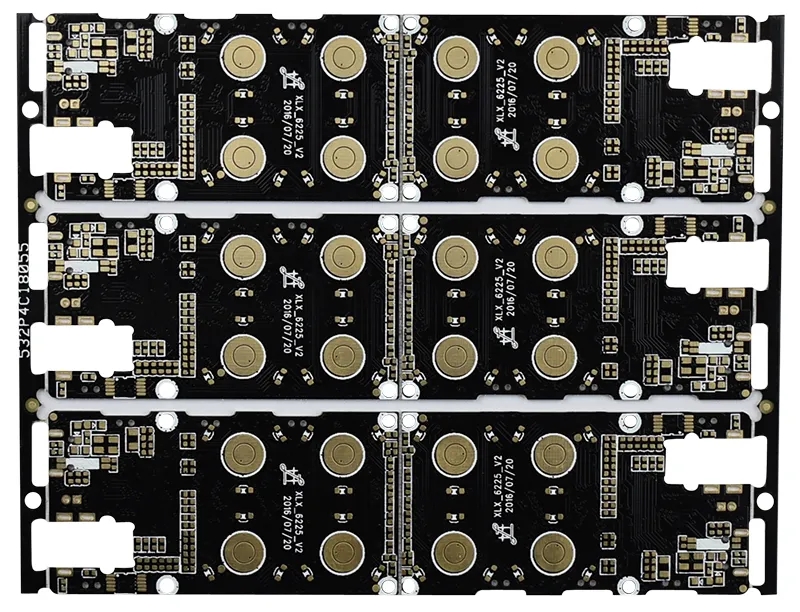

Online test ICT

On line tester (ICT), also known as flying probe (probe, needle bed) tester. Its principle is a technical means to check the lack of money in production and poor components by testing the electrical performance and electrical connection of the assembled PCBA board on board components.

When measuring with the online tester, use a special flying needle to contact the components on the welded PCBA board, and use hundreds of millivolts and current within 10 mA to conduct separate isolation tests, so as to accurately measure the faults such as missing installation, wrong installation, parameter value deviation, solder joint welding, circuit board open and short circuit of the instalLED general and special components such as resistance, inductance, capacitance, diode, triode, silicon controlled rectifier, window effect transistor, integrated block, etc, And accurately locate which component is the fault or which point the open short circuit is located.

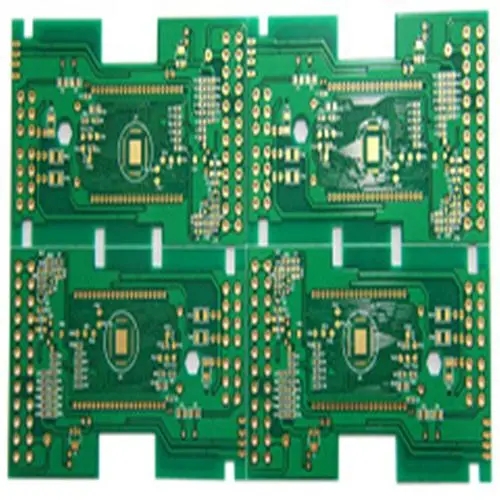

The biggest advantage of flying probe test is that it has fast MARKet reaction, but slow detection speed, which is suitable for testing samples and small batch orders. If the customer requires to print samples, the flying needle test can be selected, and the needle bed test can be changed until the customer makes a large order, which eliminates the cost of needle bed production for the customer to change the process or cancel the order.

ICT has the advantage of electrical defect testing, such as abnormal function or wrong value of devices. Online testing can effectively find out various defects and faults during assembly, but it can not completely evaluate the electrical performance of PCBA.

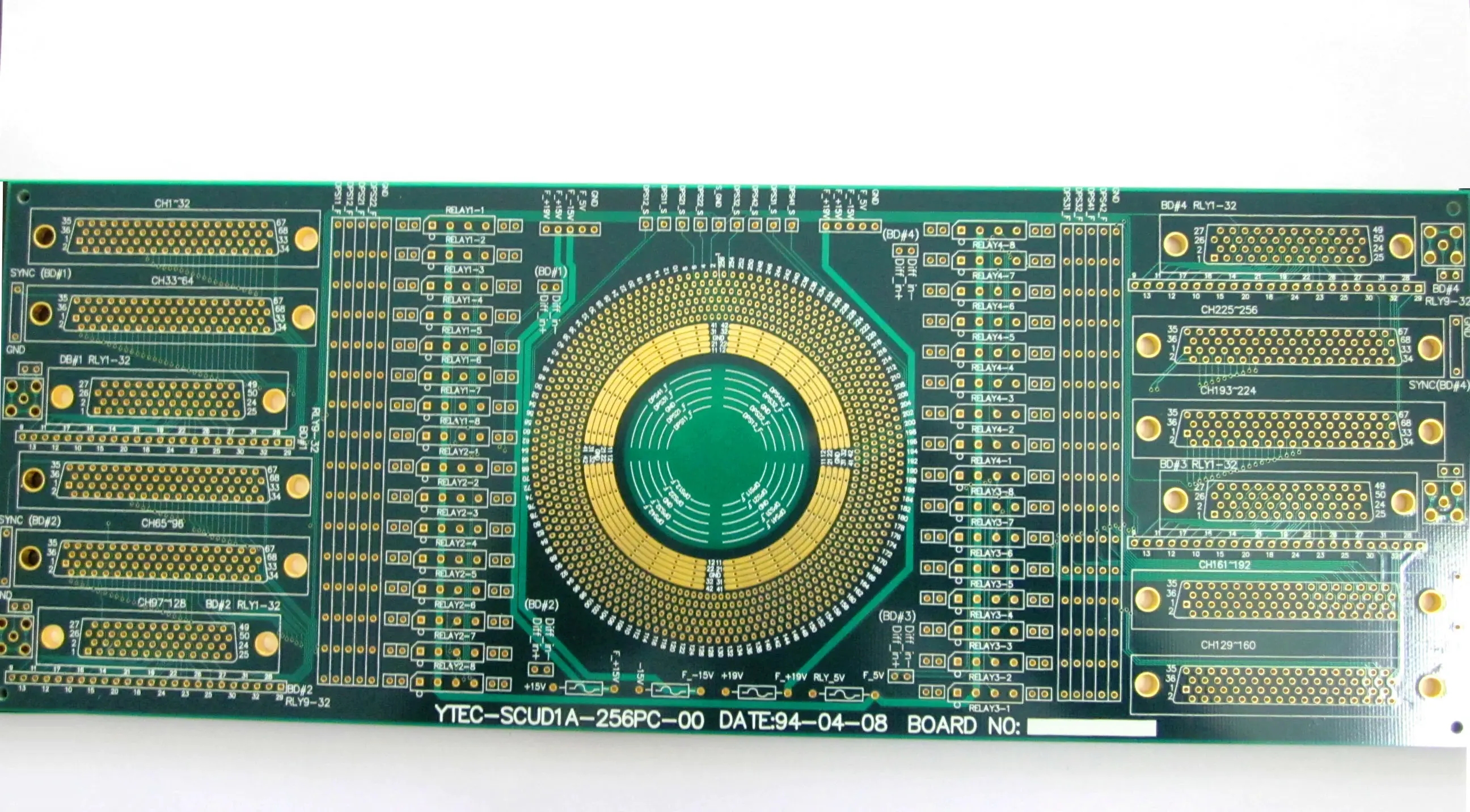

ICT needs customers' PCB design to meet ICT testability design requirements, which is troublesome to implement for the diversified levels of PCBA processing customers. In addition, the more nodes PCBA is tested, the cost will increase sharply, which is mainly consumed in the design and manufacture of needle bed or flying needle, and there is a difficult problem in testing. When the number of nodes exceeds the ICT requirements, when the physical size of PCBA exceeds the ICT requirements, the problem will be more difficult to solve.

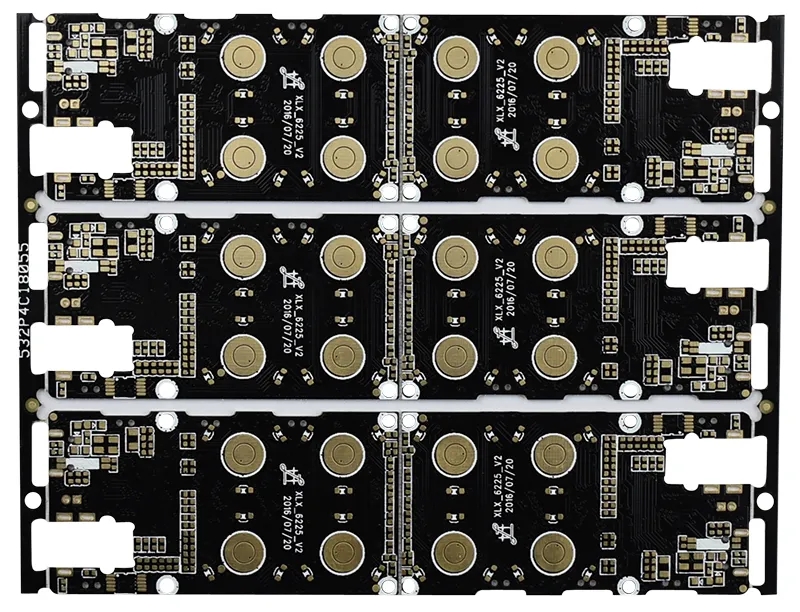

The miniaturization development of electronic products has directly led to the miniaturization (high-density integration) assembly of PCBA board design, and the value of pcba design for ICT testing will disappear. This means that production and manufacturing will face a lot of potential problems. PCBA assembly will go directly to the final inspection, which will not only lead to a decline in the qualification rate, but also increase the amount of repair and fault diagnosis costs, and will also cause production delays.