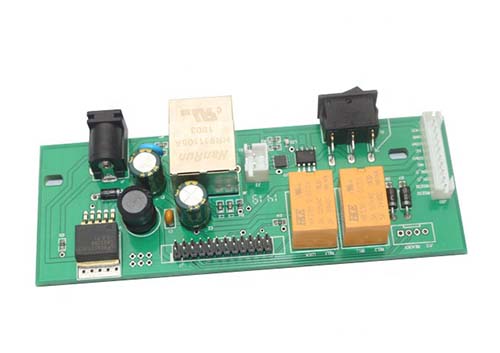

The automotive electronIC control system includes three aspects: sensors, control units and actuators. Each of the three aspects has different control functions. Controlling the engine is the most processor-intensive work on any car. It depends entirely on the engine control unit, commonly referred to as ECU or PCM.

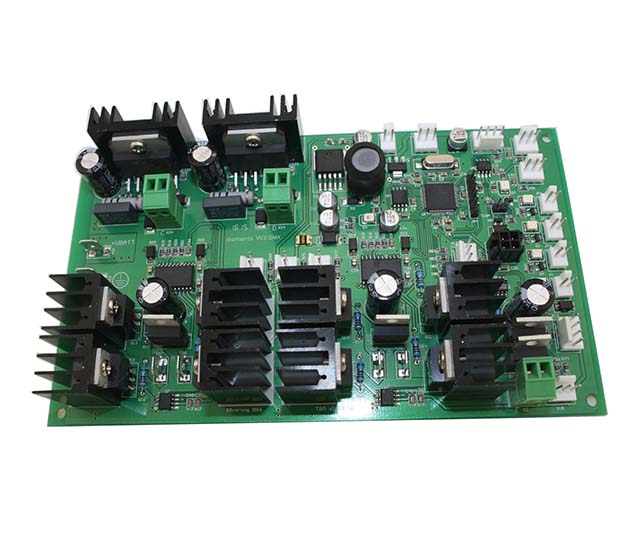

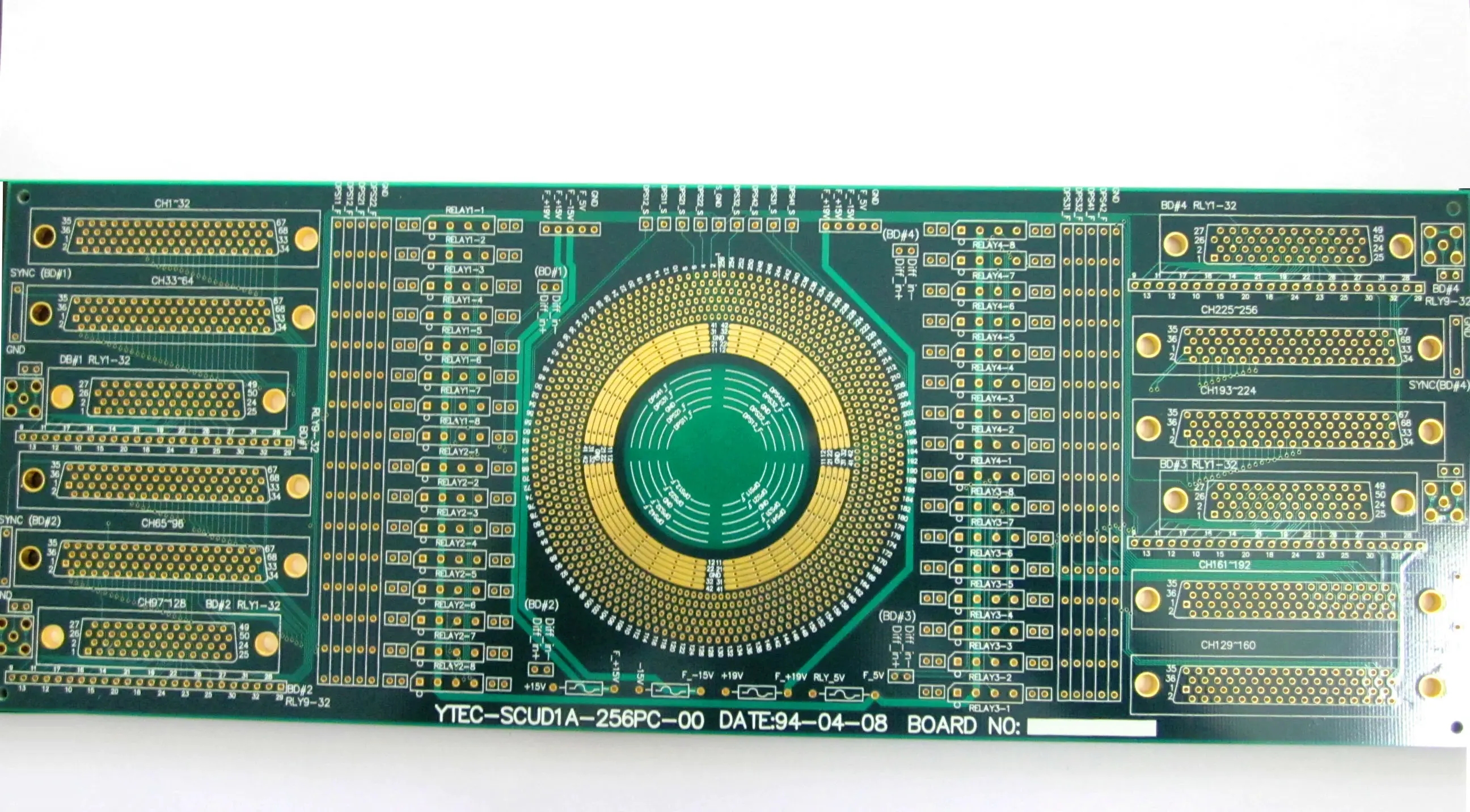

Electronic engine system PCBs generally use high-density interconnect (HDI) PCBs, high-frequency board PCBs, rigid PCBs on thick copper PCBs, ceramic substrate PCBs, aluminum-based metal core PCBs, etc. Ceramic substrate PCBs can withstand the harsh environment of the car drive normally.

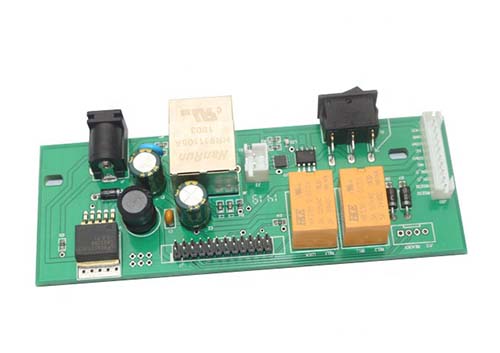

Automotive electronic engine system PCB assembly performance parameters:

Copper Thickness: 1 oz

Product Name: PCB Assembly Service

Solder mask color: White.Black.Yellow.Green.Red.Blue

Packaging: Vacuum package/ESD package

MOQ: 1 piece

Service: EMS/ODM/OEM

Certification: RoHS, ISO9001

Layers: 1-4 layers

Test: flying probe test/X-ray inspection/AOI test

kingford understands the specific quality requirements of the automotive industry, as the fastest turnkey PCBA manufacturer in the PCBA industry, we are equipped with professional PCB manufacturing equipment, including laser MARKing machine boards, laser cutting machines, CNC drilling machine, PCB laminating machine, PCB silk screen, PCB CNC machine tool, automatic PCB tester, PCB secondary element detection, PCB flying probe tester and other equipment. In PCB assembly, high-end equipment such as automatic solder paste printing machine, SPI inspection machine, ten-temperature zone nitrogen reflow oven, online AOI, X-RAY can be used to assemble your automotive engine system PCB to the highest precision and quality. We have Capability to ensure your PCBs comply with any required automotive industry standards.