Introduction

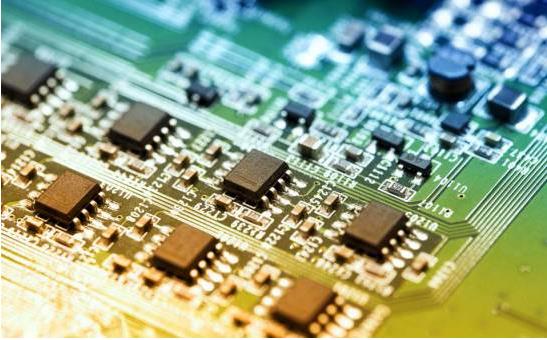

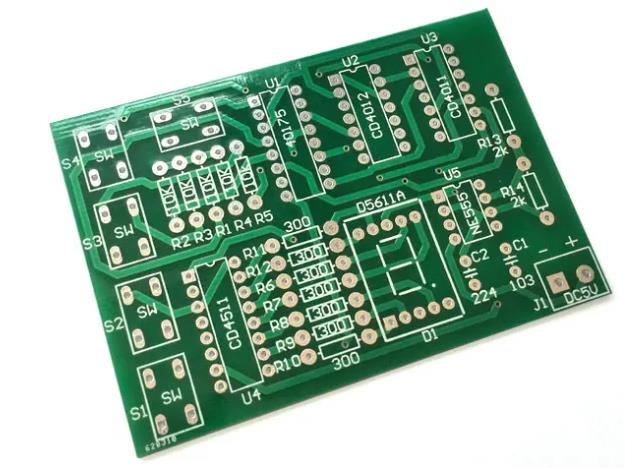

Welding is actually a chemICal process. A printed circuit board(PCB) is a support for circuit elements and devices in electronic products, and it provides electrical connections between circuit elements and devices. With the rapid development of electronic technology, the density of PCBs is getting higher and higher, and there are more and more layers. Sometimes all the designs may be correct (such as the circuit board is not damaged, the printed circuit design is perfect, etc.), but due to the Problems in the welding process lead to welding defects and a decrease in welding quality, which affects the pass rate of the circuit board, which in turn leads to unreliable quality of the whole machine. Therefore, it is necessary to analyze the factors affecting the soldering quality of printed circuit boards, analyze the causes of soldering defects, and improve these reasons to improve the soldering quality of the entire circuit board.

Causes of Welding Defects

1. The design of the PCB affects the welding quality

In terms of layout, when the PCB size is too large, although the soldering is easier to control, the printed lines are long, the impedance increases, the anti-noise ability decreases, and the cost increases; if it is too small, the heat dissipation decreases, the soldering is difficult to control, and the adjacent lines are prone to mutual interference, such as electromagnetic interference of circuit boards. Therefore, the PCB board design must be optimized: (1) Shorten the connection between high-frequency components and reduce EMI interference. (2) Components with heavy weight (such as more than 20g) should be fixed with brackets and then welded. (3) The heat dissipation problem should be considered for the heating element to prevent defects and rework caused by large ΔT on the surface of the element, and the thermal element should be kept away from the heat source. (4) The arrangement of the components should be as parallel as possible, which is not only beautiful but also easy to weld, and should be mass-produced. The circuit board design is best with a 4:3 rectangle. Do not change the wire width abruptly to avoid wiring discontinuities. When the circuit board is heated for a long time, the copper foil is easy to expand and fall off. Therefore, the use of large-area copper foil should be avoided.

2. The solderability of the circuit board holes affects the soldering quality

The poor solderability of the circuit board holes will cause virtual welding defects, which will affect the parameters of the components in the circuit, resulting in unstable conduction of the components and inner layers of the multi-layer board, causing the entire circuit to fail. The so-calLED solderability is the property of the metal surface being wetted by molten solder, that is, a relatively uniform continuous smooth adhesion film is formed on the metal surface where the solder is located. The main factors that affect the solderability of printed circuit boards are:

(1) The composition of the solder and the properties of the solder. Solder is an important part in the process of soldering chemical treatment. It is composed of chemical materials containing flux. Commonly used low-melting eutectic metals are Sn-Pb or Sn-Pb-Ag. The impurity content must be controlled in a certain proportion to prevent the oxides produced by the impurities from being dissolved by the flux. The function of the flux is to help the solder wet the circuit surface of the board being soldered by transferring heat and removing rust. White rosin and isopropyl alcohol solvents are generally used.

(2) The soldering temperature and the cleanliness of the metal plate surface will also affect the solderability. If the temperature is too high, the diffusion speed of the solder will be accelerated. At this time, it has high activity, which will rapidly oxidize the molten surface of the circuit board and the solder, resulting in welding defects. The contamination of the surface of the circuit board will also affect the solderability and cause defects. These defects Including tin beads, tin balls, open circuits, poor gloss, etc.

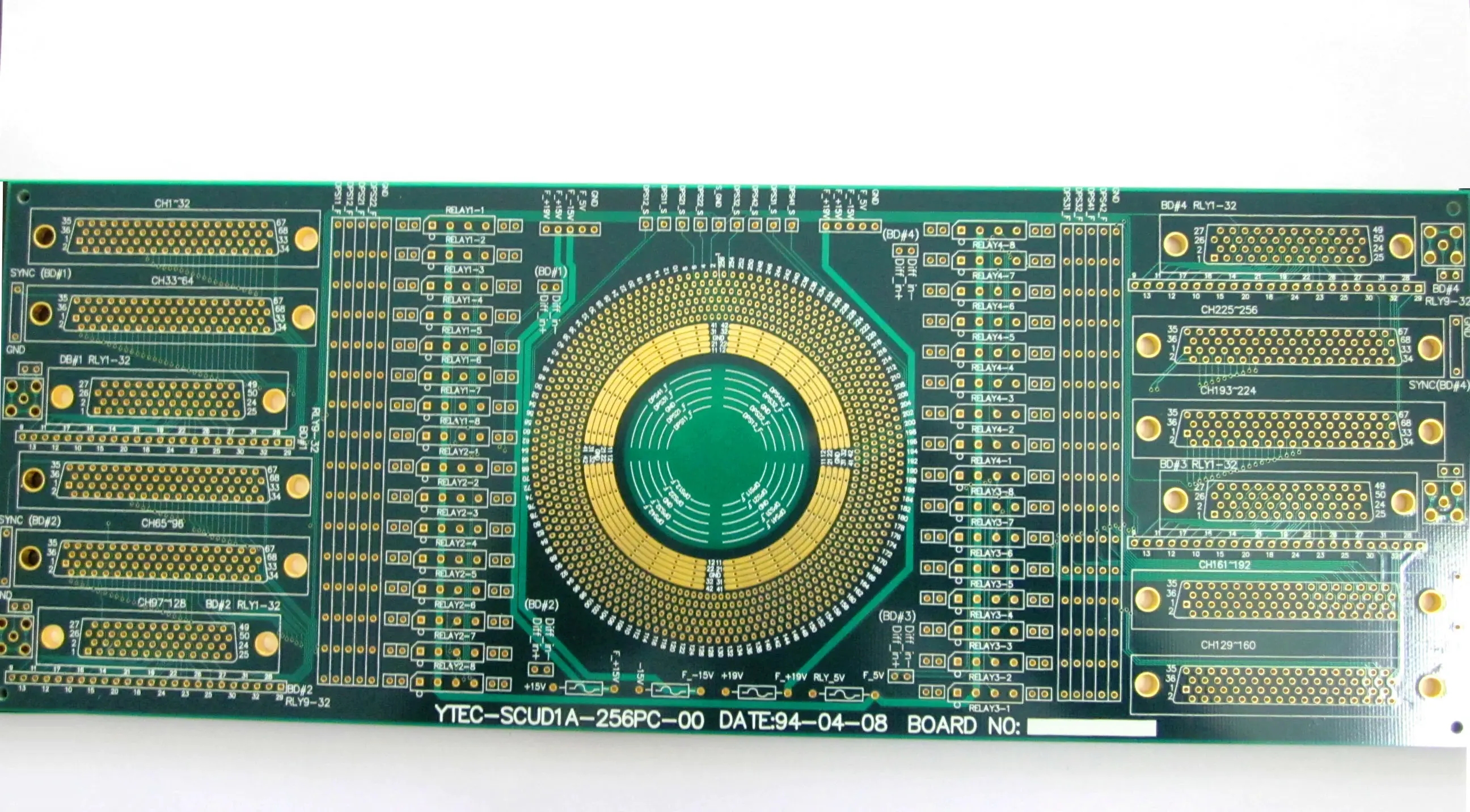

3. Welding defects caused by warpage

The PCB and components are warped during the welding process, and defects such as virtual welding and short circuit occur due to stress deformation. Warpage is often caused by an unbalanced temperature in the upper and lower parts of the PCB. For large PCBs, warping will also occur due to the board's own weight falling. Ordinary PBGA devices are about 0.5mm away from the printed circuit board. If the device on the circuit board is large, as the circuit board returns to its normal shape after cooling down, the solder joints will be under stress for a long time. If the device is raised by 0.1mm, the Enough to cause open soldering.

When the PCB warps, the component itself may also warp, and the solder joint located in the center of the component is lifted off the PCB, resulting in empty soldering. This often happens when only flux is used and no solder paste is used to fill in the gaps. When using solder paste, due to deformation, the solder paste and solder balls are joined together to form short-circuit defects. Another reason for the short circuit is the delamination of the component substrate during the reflow process. The defect is characterized by the formation of bubbles under the device due to internal expansion. Under X-ray inspection, it can be seen that the solder short circuit is often in the middle of the device. .

3. Conclusion

In summary, by optimizing the PCB design, using good solder to improve the solderability of the circuit board holes, and preventing warpage and preventing defects, the soldering quality of the entire circuit board can be improved.