Production means required for PCBA processing

Many friends do not know what production materials PCBA needs for processing, whICh leads to repeated data confirmation during processing and affects the project progress. Next, introduce the production methods required for PCBA processing.

Production materials required for PCBA processing:

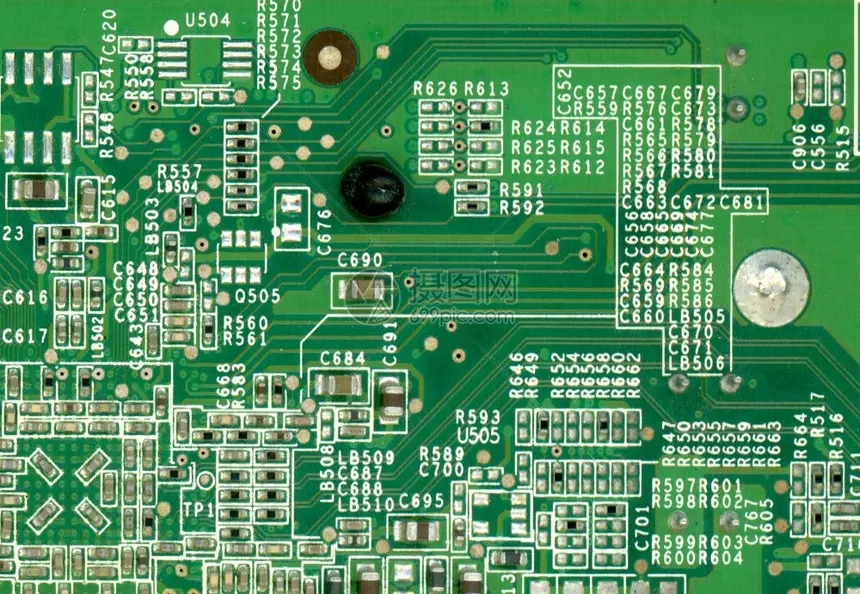

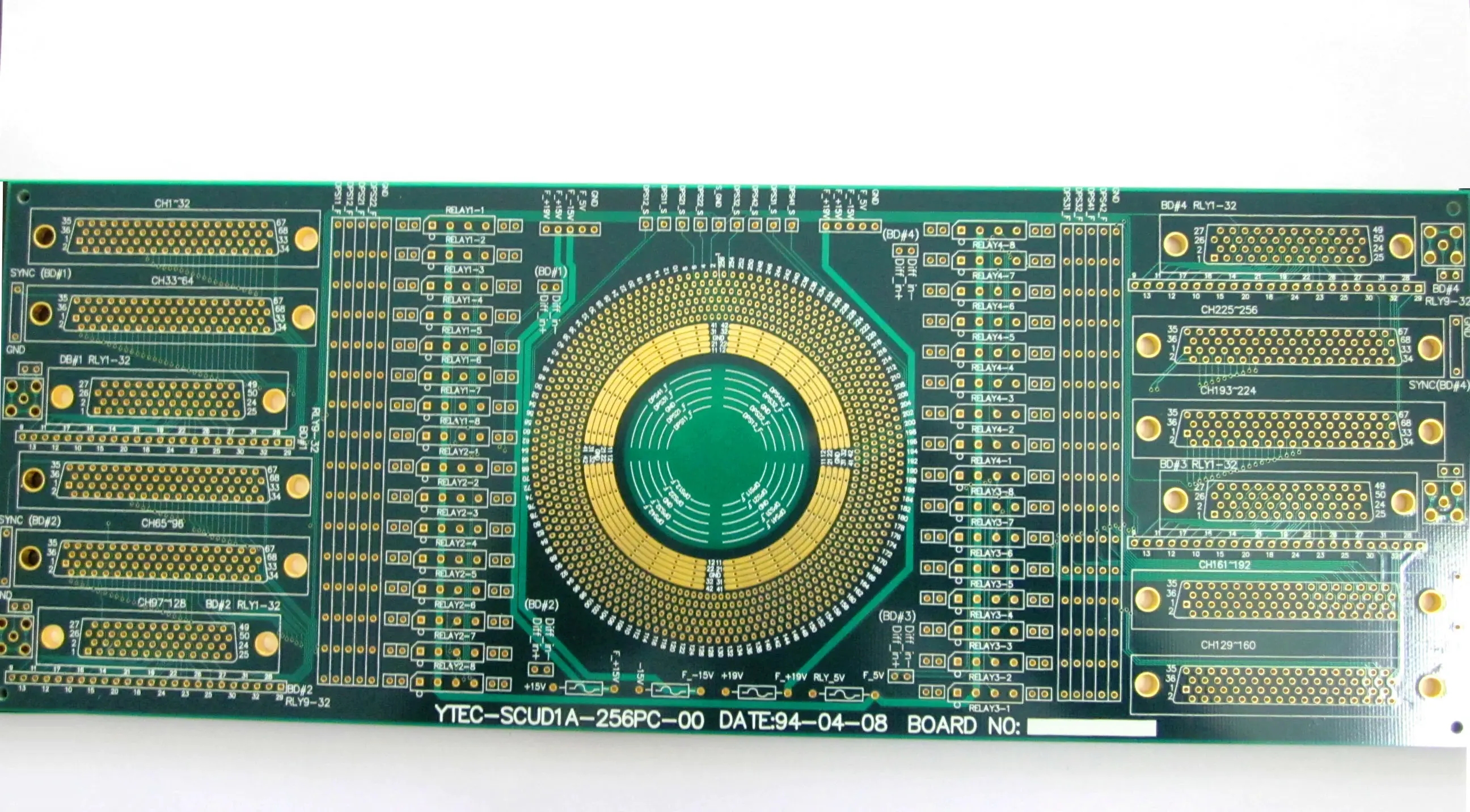

1. PCB Gerber file (layered file, which defines each layer of circuit, bonding pad, screen printing and other information, and is used to make PCB bare board);

2. BOM (bill of materials, electronic component list, including component model, brand, description, location number and consumption information);

3. MCU program (generally refers to the Chip program burned into the MCU, the encrypted file in hexadecimal or bin format, used to drive the entire PCBA logic operation and bypass control);

4. Test documents (define test point distribution, test steps and common fault diagnosis methods);

5. Upper computer software (generally refers to the software instalLED on the computer to start PCBA function item detection);

6. SMT coordinate file (exported from PCB design software to define the coordinate position of each component on the PCB for easy reading and execution by SMT mounter);

7. Other design documents (such as CAD drawings, PCB schematics, special engineering process requirements, etc.) Define post weld effect drawings.

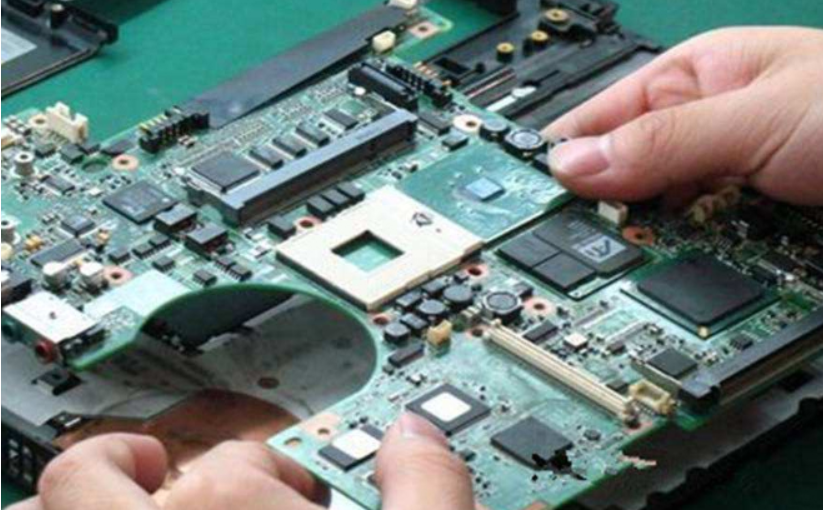

PCBA processing plant

PCBA processing capacity

1. Maximum plate: 310mm * 410mm (SMT);

2. Maximum plate thickness: 3mm;

3. Minimum plate thickness: 0.5mm;

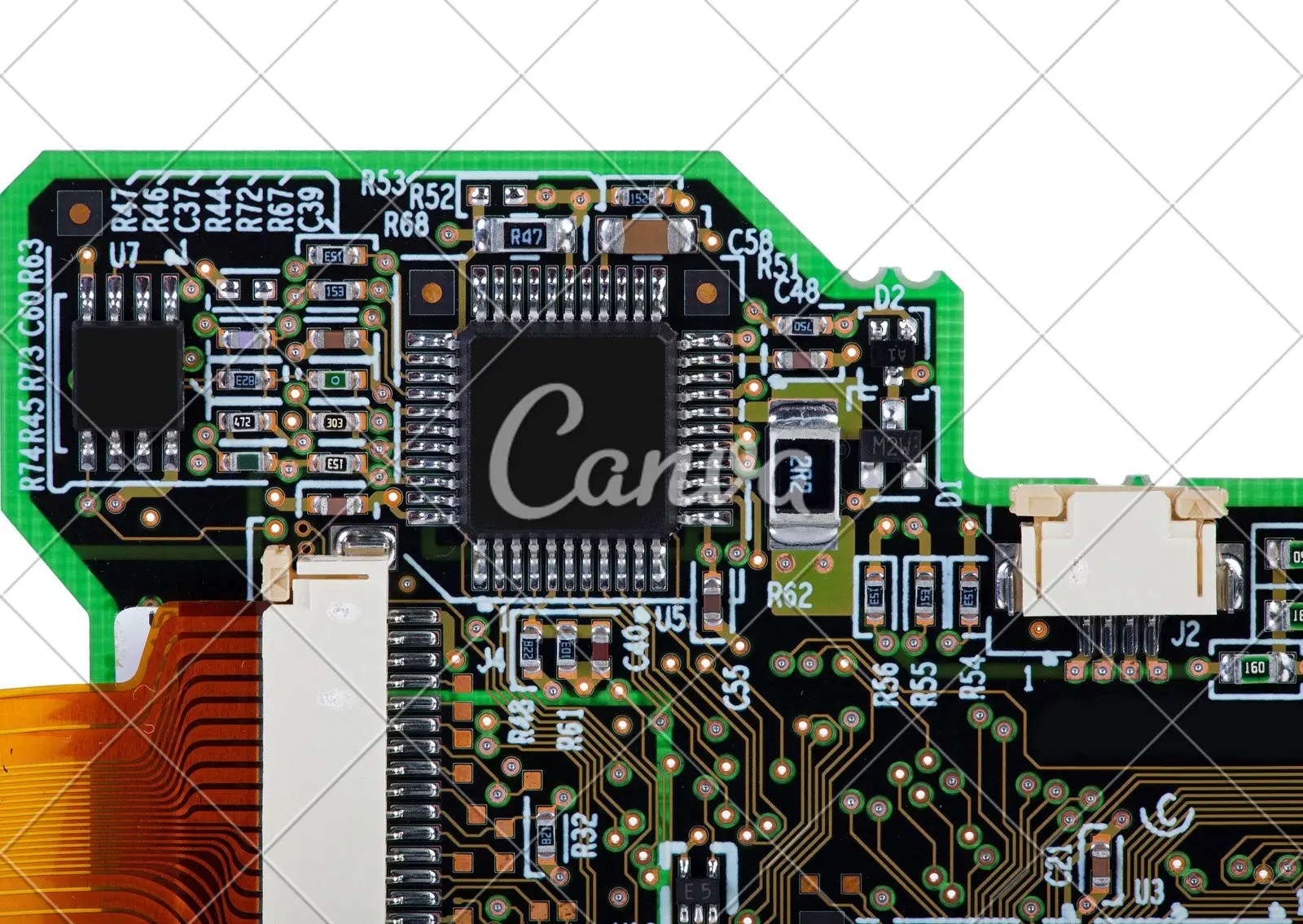

4. Minimum chip part: 0201 package or parts with a diameter of more than 0.6mm * 0.3mm;

5. Maximum weight of mounting parts: 150g;

6. Maximum part height: 25mm;

7. Maximum part size: 150mm * 150mm;

8. Minimum pin spacing: 0.3mm;

9. Minimum BGA spacing: 0.3mm;

10. Minimum ball diameter of BGA: 0.3 mm;

11. Maximum element installation accuracy (100 qfp): 25um @ IPC;

12. SMT capacity: 3-4 million points/day.

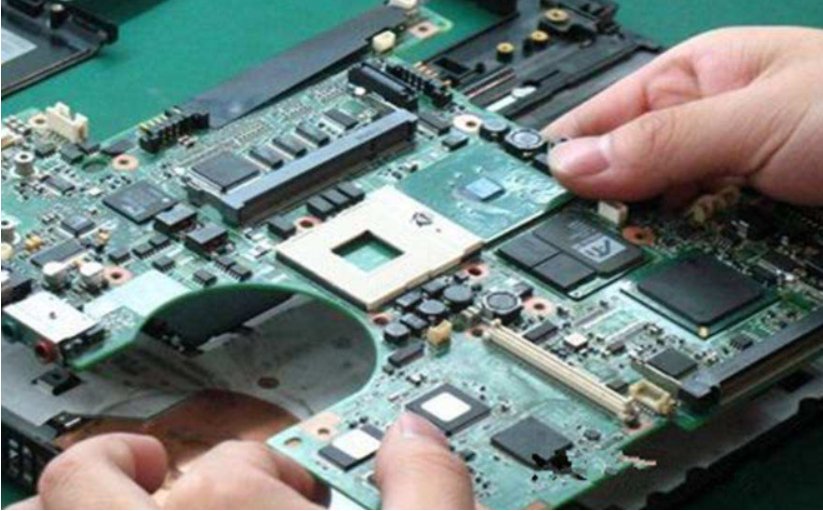

PCBA processing

PCBA processing flow

1. Customers place orders

The customer orders from PCBA processing plant according to actual needs and puts forward specific requirements. The processing factory will evaluate its ability to complete the order. If the manufacturer is confident that the order can be completed within the expected time, both parties will negotiate to determine the production details.

2. Production materials provided by customers

After the customer decides to place an order, he will provide a series of documents and lists to the PCBA processing plant, such as PCB electronic documents, coordinate files, BOM lists, etc. required for production, which must be provided.

3. Purchase raw materials

PCBA processing plant shall purchase relevant raw materials from the designated supplier according to the documents provided by the customer.

4. Incoming inspection

Before PCBA processing, all raw materials used shall be strictly inspected to ensure that they are qualified and then put into production.

In PCBA processing, in order to ensure the production quality, the manufacturer needs to strictly control the furnace temperature.

6. PCBA test

PCBA processing plant carries out strict product testing, and the PCB after testing is delivered to the customer.

7. After sales packaging

After the PCBA processing is completed, the product is packaged and handed over to the customer to complete the whole PCBA processing.

This article mainly introduces the production methods required by PCBA processing plant in the process of PCBA processing and production