Performance test of common PCBA circuit boards

PCBA circuit board performance test is a necessary test to ensure the stability of product performance after PCBA processing. According to the actual use environment and purpose of the product, it is generally divided into withstand voltage test, insulation test, salt spray test, impedance test, vibration test, high temperature and humidity test, welding strength and thrust test, etc. Next, we will introduce the performance test of these PCBA circuit boards in detail.

1. Voltage withstand test

The purpose of withstand voltage test is to test the withstand voltage capability of the circuit board. The equipment needed is a "withstand voltage tester".

Test method: Connect the PCBA circuit board to be tested to the tester, increase the voltage to 500V DS (DC) at a speed not higher than 100V/S, and keep it for more than 30 seconds. If there is no fault in the circuit, the test is passed.

2. Leakage current test

The purpose of the leakage current test is to check whether the leakage current of the circuit board is within the requirements. The equipment needed is the "leakage current tester".

Test method: simulate the leakage current between the accessible part of the product and the two power supply poles under the normal working condition of PCBA circuit board and the normal temperature of the circuit board. If the current is less than the design standard, the test will be passed.

3. Salt spray test

The purpose of the salt spray test is to check the corrosion resistance of the circuit board. The equipment needed is the "salt water spray tester"

Test method: First of all, we need to prepare salt solution. The preparation method is: use chemICally pure sodium chloride and distilLED water or deionized water with a resistivity of no less than 5000 ohms * CM. Use 5% sodium chloride and 95% water to prepare a salt solution with a sodium chloride content of 5 ± 1% after full mixing. After the salt solution is prepared, spray continuously for 48 hours at a test site with a temperature of 35 ℃, and the average amount of spray per hour should reach 80CMm2/10CM. After 48 hours, if all functions of the product are normal, and the appearance and structure are normal, the test will be passed.

4. Impedance test

The purpose of impedance test is to check whether the circuit board circuit can operate normally. The equipment needed is an "ohmmeter"

Test method: Connect the transmission line of the circuit board to the battery. If we measure the impedance in a shorter time than the reflection of the transmission line, we can get the "surge" impedance or characteristic impedance. However, if the waiting time is long enough until the energy is reflected back and received, we can find that the impedance changes through measurement. Generally speaking, the impedance value will reach a stable limit value after bouncing up and down. If the limit value is within the specified range, Then the test is passed.

5. Vibration test

The purpose of vibration test is to detect whether the circuit board can pass random vibration tests of different levels. The equipment needed is a "vibration meter"

Test method: fix the circuit board or packaged circuit board on the test bench, set the frequency at 20Hz, axial direction: X, Y, Z, lasting for one hour in each direction for a total of three hours. After the test, if the circuit board functions normally, its appearance and structure are normal, and no abnormality such as loose welding or cracking of components is found, the test is passed.

6. High temperature and humidity test

The purpose of the high temperature and high humidity test is to check the applicability of the circuit board under the harsh conditions of high temperature and high humidity. The equipment needed is the "constant temperature and humidity test chamber".

Test method.

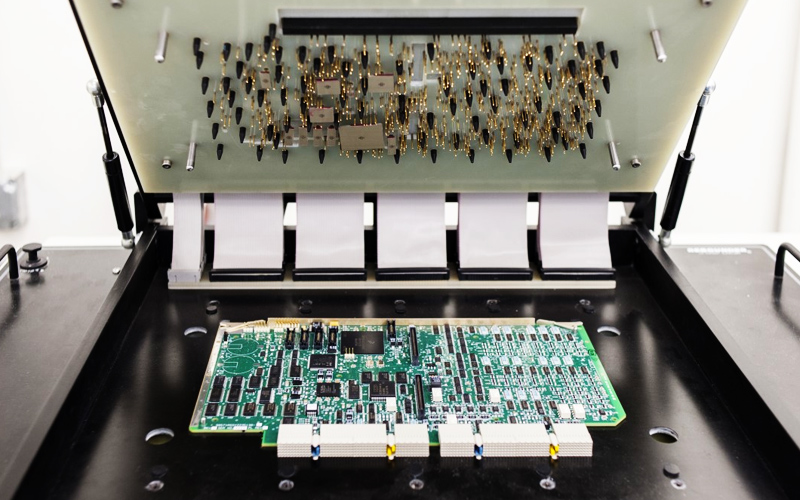

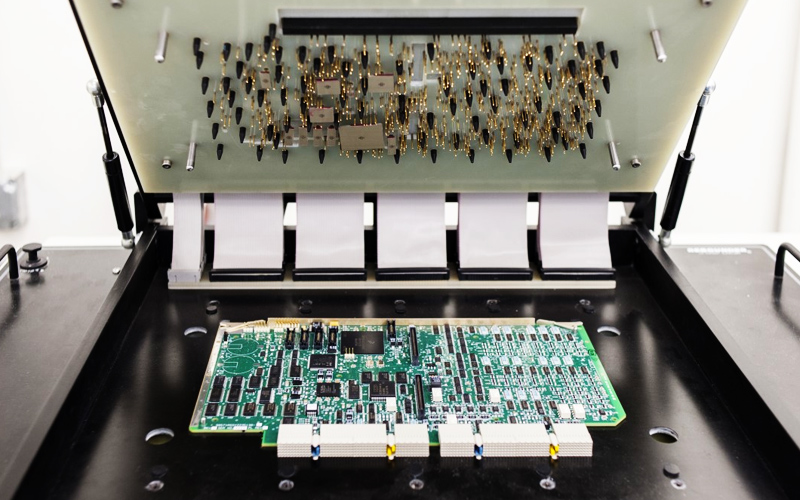

7. Welding strength thrust test

The purpose of welding strength thrust test is to test whether the welding strength of components meets the requirements. The equipment needed is a "thrust meter"

Test method: place the welded PCBA circuit board on the thrust meter. Components of different specifications have different passing requirements. Generally, we will eliminate other components at the edge of the target component, and then reset the instrument to zero. Carry out the thrust test at an angle ≤ 30 degrees to check whether the components are soldered, and record the value of component soldering.

The thrust standard of components with common specifications is 0.65Kgf for components with 0402 specifications, 1.20Kgf for components with 0603 specifications, 2.30Kgf for components with 0805 specifications, and 3.00Kgf for components with 1206 specifications.

The above are seven common PCBA circuit board performance test methods. You can choose different test methods according to your actual product situation.