When manufacturing and assembling printed circuit boards, the quality of the finished product will be one of your main concerns.

In order to achieve the highest level of manufacturing quality, it is important to find a good manufacturer like Kingford that follows established PCB and assembly quality control methods.

kingford supplies printed circuit boards, assemblies and electronic systems.

We will provide safe, effective and reliable products while providing our customers with the highest quality and value.

Kingford has a constant desire to achieve excellence in different stages of manufacturing and product control and is accredited by important international certification bodies recognized by the global electronics industry.

Incoming Quality Control

Incoming inspection refers to the quality confirmation and inspection of the purchased raw materials, components, or products, that is, the quality of the raw materials or components is inspected by sampling when the supplier sends the raw materials or components, and the final judgment is made whether the batch of products is accepted or rejected Receive.

Choosing a trustworthy platform is another important way to get high-quality components. Such companies fulfill the requirement of the customers precisely.

Besides, they provide high-quality parts after passing them from the testing pipeline.

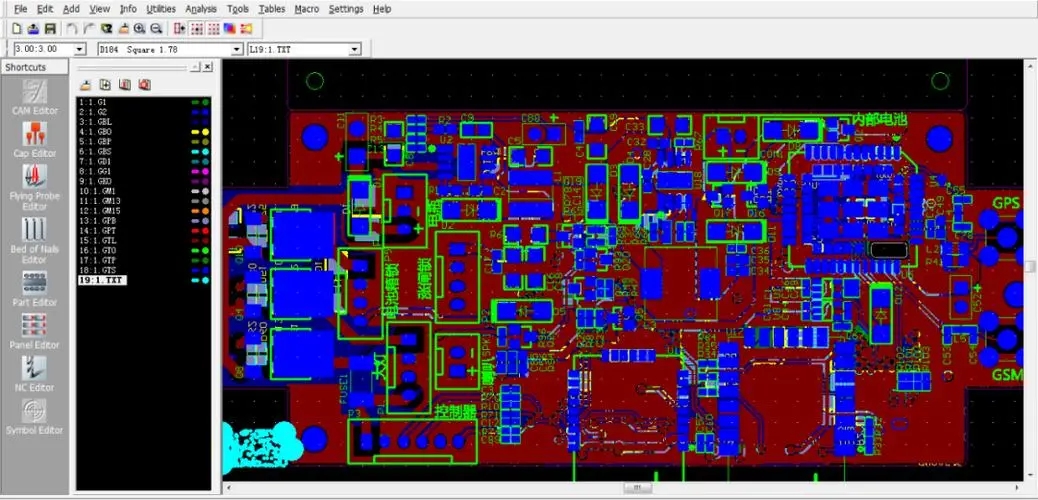

Free DFM Check

In kingford, we provide free DMF check for our clients, normally there’re including five aspects as signal and mixed layer checks, power/ground checks, drill checks, solder mask checks, silkscreen checks, to ensure every detail is correct, our engineers send engineering query to our clients when they find any information is not matched to the original files.

First Article Inspection

The first article inspection system is a quality management system that integrates testing equipment and data platform.

You only need to enter the BOM of products, and the testing unit in the system will automatically test the first sample and check the data in the BOM.

The automatic working method of this kind of system can reduce human error, improve efficiency, and save labor costs, but the investment in assets and technology is relatively large.

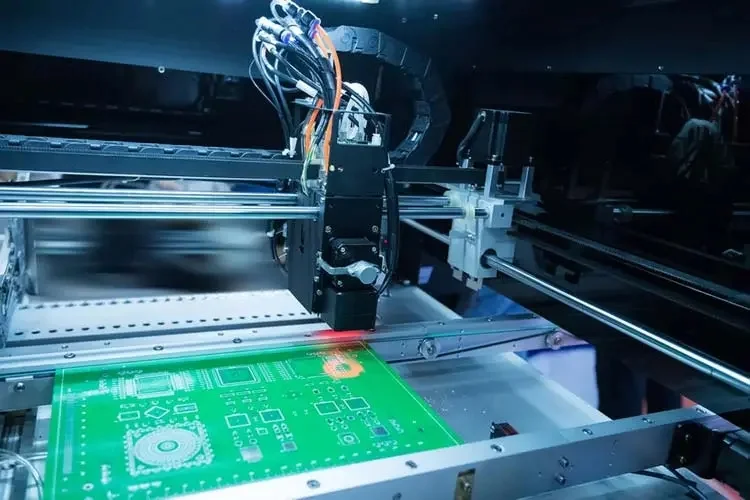

Automated Optical Inspection (AOI)

Automated Optical Inspection (AOI) test is very common in the SMT industry and is suitable for all circuit board production and PCB assembly.

It is mainly used to determine the soldering problems of the components through the appearance characteristics of the components.

It can also be determined by checking the color of the components and the silkscreen on the IC, whether the components on the circuit board have wrong parts or not.

Basically, every SMT production line will be equipped with one or two AOI equipment as standard.

Automatic X-ray inspection

For some circuit boards with BGA packaged components, X-ray inspection is required for the first product produced.

X-ray has strong penetrability and is the earliest instrument used in various inspection occasions.

The perspective view can show the thickness, shape, and quality of solder joints and solder density.

These specific indicators can fully reflect the welding quality of the solder joints, including open circuits, short circuits, hole copper, internal bubbles, and insufficient tin, and can be quantitatively analyzed.

Automatic FixtureTester

Auto fixture testing is usually used in the mass production of PCBs.

Its characteristic is that the production volume is usually relatively large and the test efficiency is high, but the manufacturing cost is relatively large.

Each type of circuit board requires a special fixture, and each set of fixtures life is not very long, normally it’s one year.

In order to meet customer quality and delivery requirements, Kingford purchases many automatic test fixtures to reduce labor costs.

Burn-In Test

The main purpose of the burn-in test is to simulate the daily use environment of the product through the combined effects of high temperature, low temperature, high and low-temperature changes, and electrical power, and expose the defects of PCBA, such as poor soldering, mismatch of component parameters, and the debugging process.

In order to eliminate and improve, will play a role in stabilizing parameters for the defect-free PCBA board.

Fly Probe Test

The fly probe test is usually used in some small batch production.

It is characterized by convenient testing, strong program variability, and good versatility.

It can basically test all types of circuit boards. But the test efficiency is relatively low, and it takes much time to test each board.

This test needs to be carried out after the product passes through the reflow furnace.

It mainly measures the resistance between two fixed points to determine whether the components in the circuit board have short circuits, empty soldering, and wrong parts.

In-Circuit Test

In Circut Test is usually used on models that have been mass-produced, and the amount of production is usually relatively large, and the test efficiency is high, but the manufacturing cost is relatively large.

Each type of circuit board requires special fixtures and the test cost is very high.

The test principle is similar to the flying probe test. It also measures the resistance between two fixed points to determine whether the components on the circuit have short circuits, empty soldering, and wrong parts.

Function Test

This test method is usually used on some more complicated circuit boards.

The circuit boards that need to be tested must be soldered and passed through some specific fixtures to simulate the formal use of the circuit board.

Place the circuit board in this simulation. In the scene, after turning on the power, observe whether the circuit board can be used normally.

This test method can accurately determine whether the circuit board is normal. But there are also problems of low test efficiency and high test costs.

PCB Quality Assurance:

To satisfy our customer’s PCB Fabrication and PCB Assembly with top quality.

kingford has implemented the ISO9001 quality system.

The perfect quality assurance system and various inspection equipment help us to monitor the whole production process, assure stability of this process, and high product quality, meanwhile, advanced instruments and technology methods have been introduced to attain sustained improvement.

Quality Policy

Quality first, customer first, continuous improvement, most excellence

Environment Policy

Strictly obey the legislations and regulations for pollution prevention.

Continually improve the processes for saving the resources usage.

Progressively manufacture the environment-protected products for the benefits of human society

Health and Safety Policy

Strictly obey the legislations and regulations for employee health and safety.

Continually create a healthy and safe working environment.

Progressively prevent the potential risk of endangering health and safety.

Quality

100% visual inspection and electrical test

Test data

IPC

Certification- ISO 9001

XRF test data

Solderability test

Impedance modeling/testing

PCB Assembly Quality Assurance:

To enhance quality control comprehensively, we must realize our quality policy and goal.

Quality System is established according to ISO9001:2015 with regular internal audit to guarantee quality system is effectively operated.

All staffs are participated in the quality system, by keeping training and learning. Customer ssatisfication is our mission.

IQC: Incoming Materials Inspection

First Article Inspection for every process

IPQC: In-Process Quality Control

AOI testing

In-circuit Test (ICT)

Functional test (FCT)

Reliability test