Multilayer flexible PCB design manufacturer

Name: Multilayer flexible PCB design manufacturer

Designable layers: 1-32 layers

Minimum line width and line spacing: 3mil

Minimum laser aperture: 4mil

Minimum mechanical aperture: 8mil

Copper foil thickness: 18-175цm (standard: 18цm35цm70цm)

Peel strength: 1.25N/mm

Minimum punching hole diameter: single side: 0.9mm/35mil

Minimum hole diameter: 0.25mm/10mil

Aperture tolerance: ≤φ0.8mm±0.05mm

Hole tolerance: ±0.05mm

Hole wall copper thickness: double-sided/multi-layer: ≥2um/0.8mil

Hole resistance: double-sided/multi-layer: ≤300цΩ

Minimum line width: 0.127mm/5mil

Minimum pitch: 0.127mm/5mil

Screen printing color: black, white, red, green, etc.

Surface treatment: lead/lead-free tin spray, ENIG, silver, OSP

Service: Provide OEM service

Certificate: ISO9001.ROSH.UL

Flexible printed circuits have many benefits, including:

Reduce Assembly Errors - Through precise design and automated production, flex circuits eliminate human error in manual wiring harnesses. Except for errors caused by production, circuits are routed only to those points required by the exact design plan.

Reduced assembly time and cost - Flex circuits require less labor during assembly and reduce production errors. Flexible circuits have an inherent ability to integrate form, fit and function. Flex circuits eliminate the high cost of routing, wrapping and soldering wires. Install or replace a complete interconnect system instead of individual hard PC boards. As a result, wiring errors are eliminated, thereby reducing manufacturing costs. Assembly time and cost can be reduced, whether for low-volume production of complex circuits or high-volume production of simple circuits.

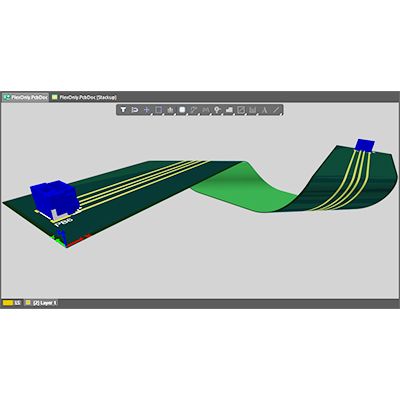

Design freedom - Unlike rigid circuit boards, flex circuits are not limited to two dimensions. Because they are as flexible as wire or ribbon cables, the flex circuit design options are endless. At Flexible Circuit, we pride ourselves on being able to tackle the most complex design challenges. Flexible circuits can be designed to meet highly complex and unimaginable configurations, while being able to operate in the harshest environments.

Name: Multilayer flexible PCB design manufacturer

Designable layers: 1-32 layers

Minimum line width and line spacing: 3mil

Minimum laser aperture: 4mil

Minimum mechanical aperture: 8mil

Copper foil thickness: 18-175цm (standard: 18цm35цm70цm)

Peel strength: 1.25N/mm

Minimum punching hole diameter: single side: 0.9mm/35mil

Minimum hole diameter: 0.25mm/10mil

Aperture tolerance: ≤φ0.8mm±0.05mm

Hole tolerance: ±0.05mm

Hole wall copper thickness: double-sided/multi-layer: ≥2um/0.8mil

Hole resistance: double-sided/multi-layer: ≤300цΩ

Minimum line width: 0.127mm/5mil

Minimum pitch: 0.127mm/5mil

Screen printing color: black, white, red, green, etc.

Surface treatment: lead/lead-free tin spray, ENIG, silver, OSP

Service: Provide OEM service

Certificate: ISO9001.ROSH.UL