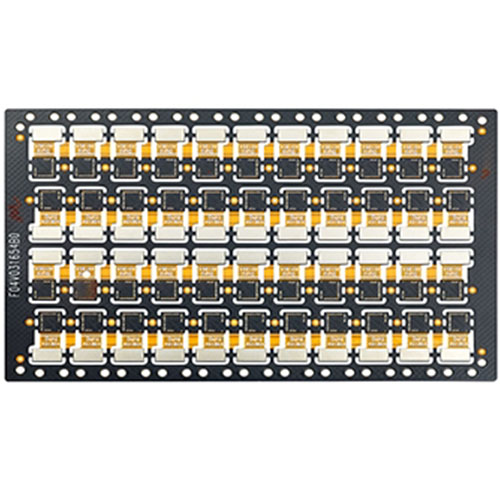

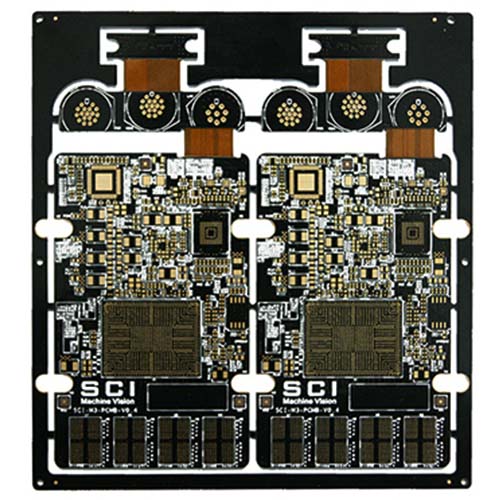

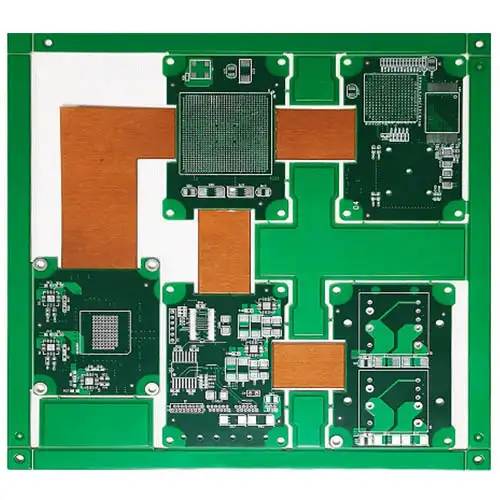

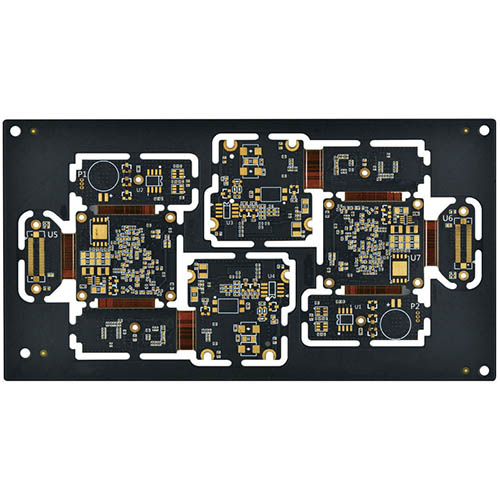

TWS Earphone Rigid Flex PCBs

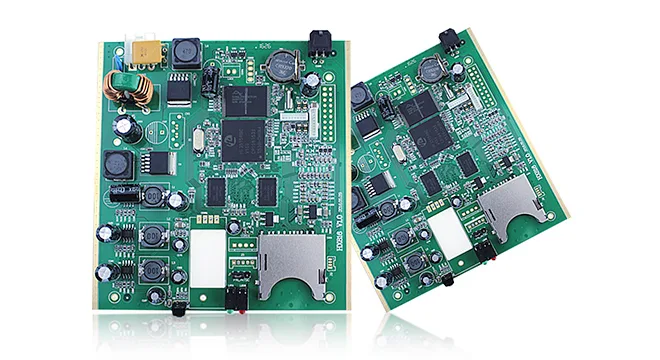

Name: TWS Earphone Rigid Flex PCBs

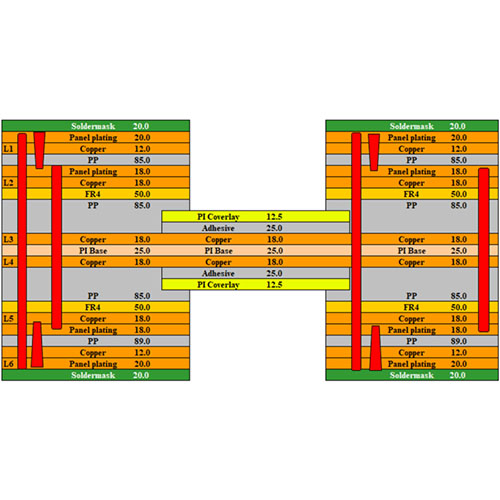

Layers: 6L

Structure: 2R+2F+2R (HDI structure)

Plate thICkness: 1.0mm

Outer copper thickness: 1 OZ

Inner copper thickness: 1 OZ

Minimum aperture: 0.2mm

Minimum line width/line spacing: 3mil

Surface Treatment: Immersion Gold

Product use: TWS bluetooth headset

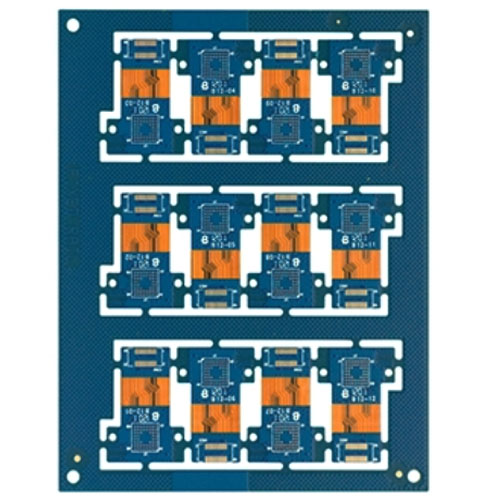

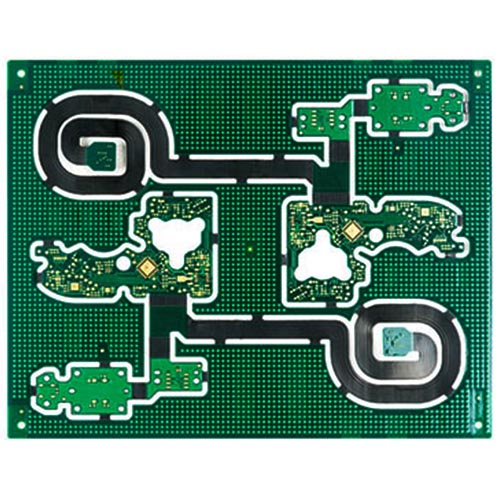

Process difficulty: The Rigid Flex PCBs are 1st-order HDI structure rigid flex PCBs

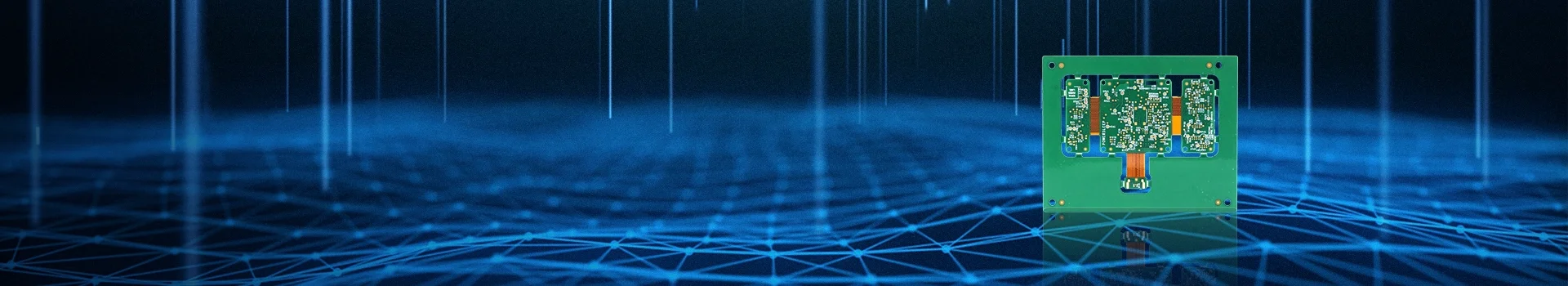

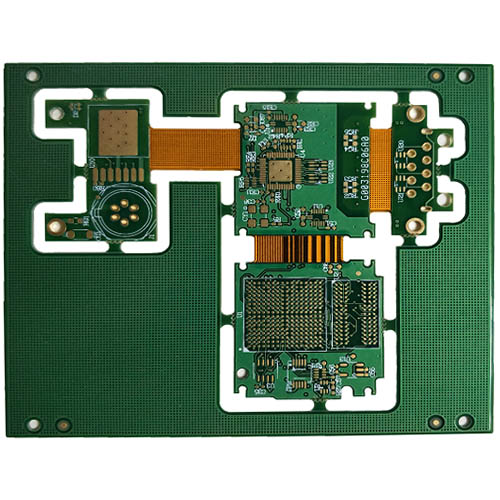

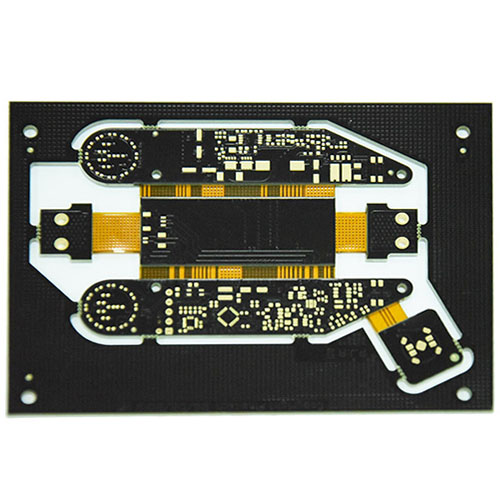

Rigid Flex PCB printed circuit board with Green Solder Mask Ink

1. High heat resistance and high temperature resistance, can withstand 280 degrees Celsius within 10 seconds and 150 degrees Celsius for a long time.

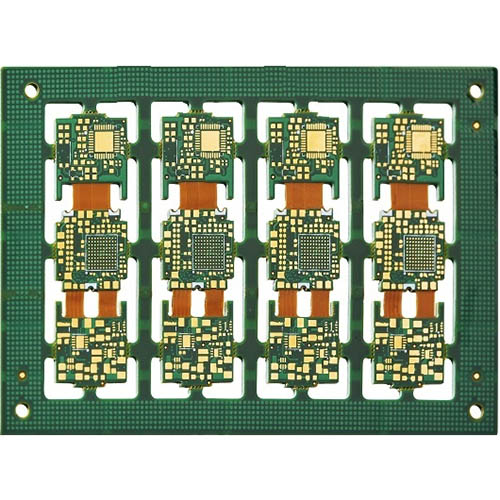

2. Multilayer circuits, where some layers are rigid boards and some are flexible circuits.

3. Excellent electronIC and dielectric properties.

4. Two-in-one circuits are interconnected through plated-through holes.

5. Green solder mask ink on solder mask.

6. In most rigid flex circuit boards, the circuit consists of multiple flex circuit inner layers that are selectively joined together using epoxy prepreg adhesive films, SIMilar to multi-layer flex circuits.

7. Offers higher component density and better quality control.

8. Apply OSP and Immersion Gold finish to pads and headers.

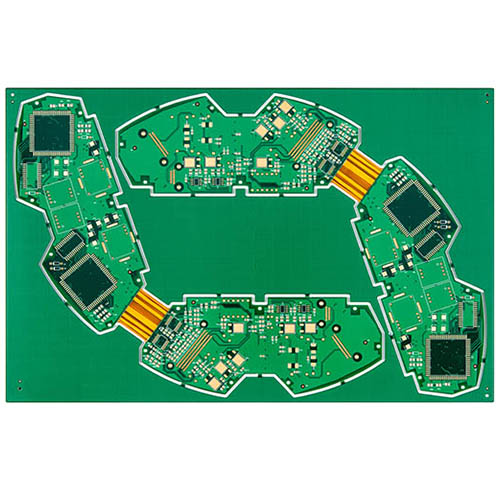

9. Multilayer rigid flex circuits can be designed externally, internally or a combination of both as needed.

10. Rigid-flex circuits combine the advantages of rigid circuit boards and flexible circuits into one circuit.

11. The design is rigid where extra support is required, and flexible in corners and areas that require extra space.

Name: TWS Earphone Rigid Flex PCBs

Layers: 6L

Structure: 2R+2F+2R (HDI structure)

Plate thICkness: 1.0mm

Outer copper thickness: 1 OZ

Inner copper thickness: 1 OZ

Minimum aperture: 0.2mm

Minimum line width/line spacing: 3mil

Surface Treatment: Immersion Gold

Product use: TWS bluetooth headset

Process difficulty: The Rigid Flex PCBs are 1st-order HDI structure rigid flex PCBs

- Previous:No

- Next:Four-layer rigid-flex board