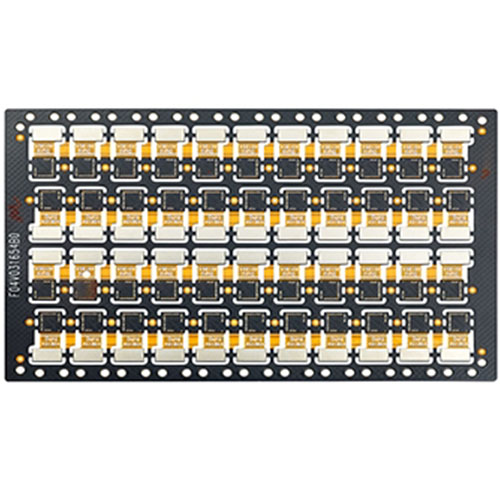

8L rigid-flex board

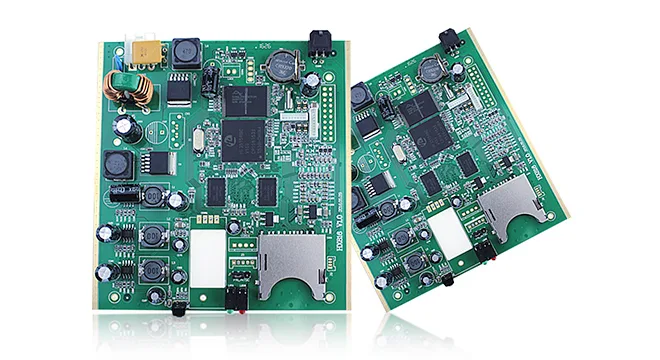

Name: 8L rigid-flex board

Layers: 8L

Plate thICkness: 1.45mm

Minimum aperture: 0.25mm

Minimum line width/line spacing: 5/3.6mil

Inner layer copper thickness: HOZ

Outer copper thickness: 1OZ

Surface treatment: chEMIcal gold ENIG

Minimum distance from hole to line: 0.25mm

Application field: consumer electronics

The panels in an 8-layer rigid-flex PCB offer several advantages to the PCB. The panel format allows for easier assembly of components, reducing overall delivery time. A good panel layout will also speed up testing and inspection time, reducing time-to-MARKet risk. Properly planning the panel layout allows engineers to increase the number of circuits in a PCB. These circuits can be designed to be placed close together to maximize the use of panel space. These different steps result in lower manufacturing costs and customer spending. Due to these advantages, product manufacturers in different industrial fields have opted for 8-layer rigid-flex PCBs in the form of panels.

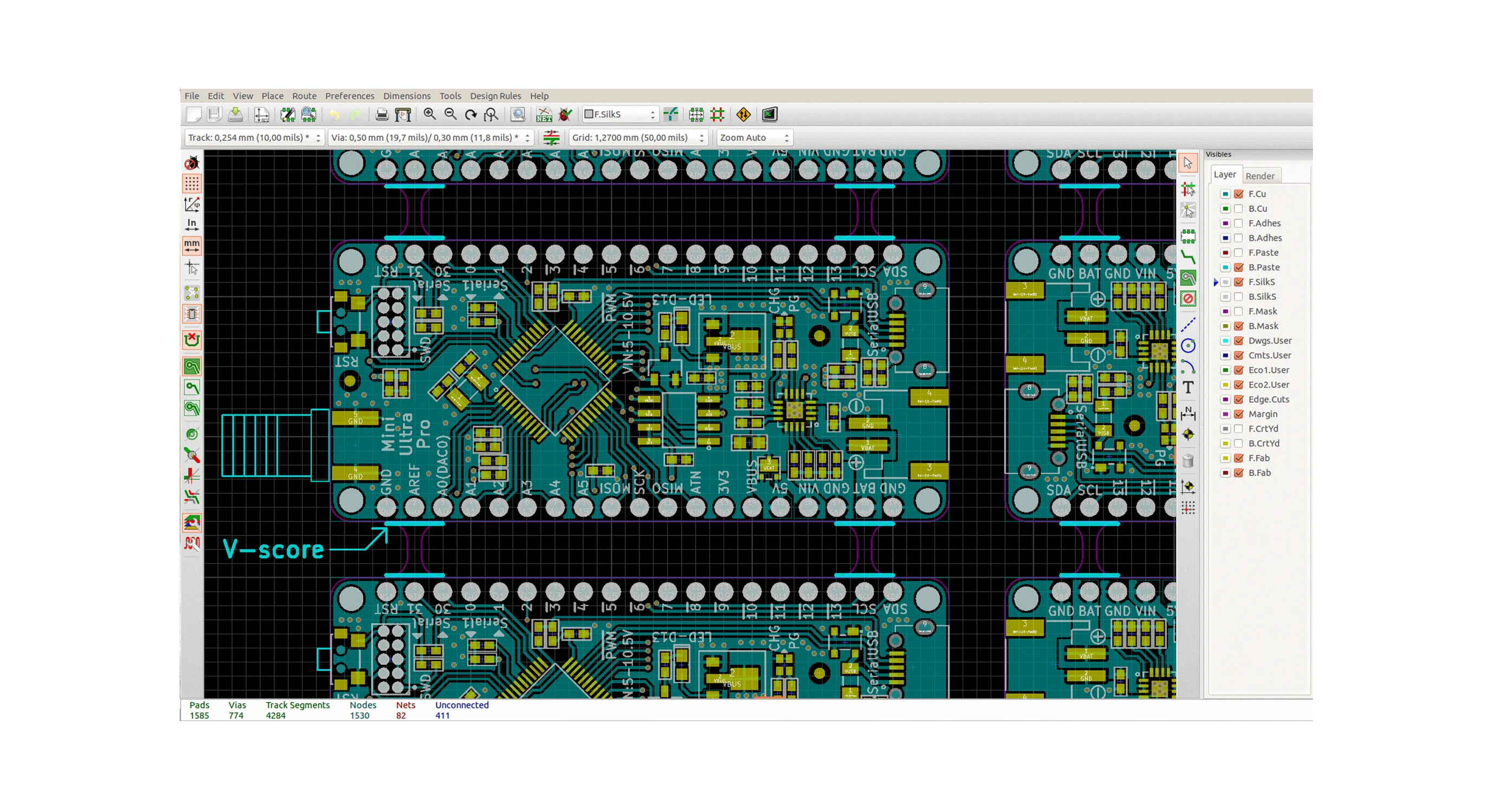

At kingford, the 8-layer rigid-flex PCB in panel form is made of FR4+ polyimide material and treated with HASL, Immersion Gold, HASL, OSP for enhanced surface protection. These boards are manufactured with Width/Pitch: 4/4mil, Finish ThICkness: 0.2mm (flexible), 1.6mm, Min Thermal: 0.4mm, board Thickness 0.5mm~3.0mm (0.02"~0.12"), Copper Thickness: 0.5oz , 1.0 oz, 2.0 oz, 3.0 oz, up to 6 oz. Solder mask color selection to highlight components of flex PCB white/black/blue/green/red, Taiyo PSR4000 white.

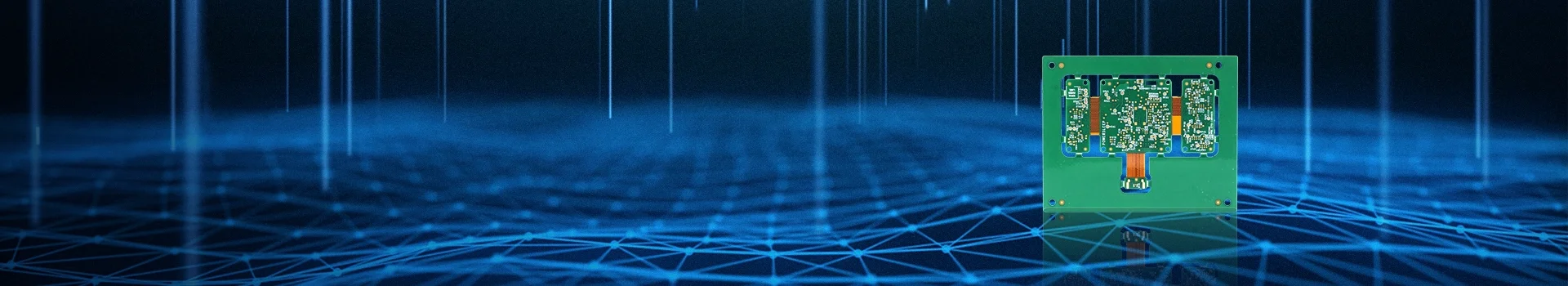

We see quality and credibility as the key to meeting the dynamic needs of our customers. Our Rigid Flex PCBs undergo rigorous testing, which helps us make the most accurate, timely and cost-effective designs. With the highest quality results and prompt service, our products meet the needs of many different markets, including the automotive, electronics, telecommunications, military, aerospace and defense industries.

Name: 8L rigid-flex board

Layers: 8L

Plate thICkness: 1.45mm

Minimum aperture: 0.25mm

Minimum line width/line spacing: 5/3.6mil

Inner layer copper thickness: HOZ

Outer copper thickness: 1OZ

Surface treatment: chEMIcal gold ENIG

Minimum distance from hole to line: 0.25mm

Application field: consumer electronics