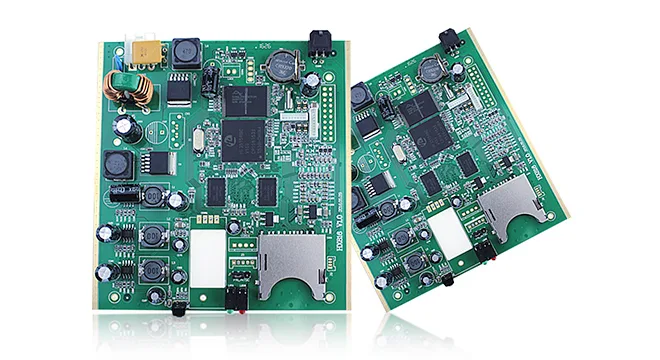

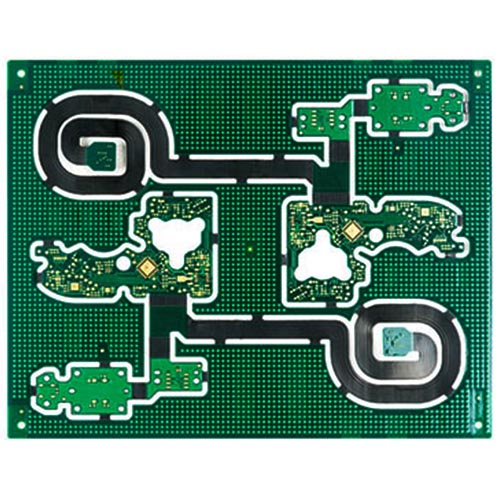

Four-layer rigid-flex board

Name: Four-layer rigid-flex board

Structure: 1R+2F+1R

Layers: 4L

Plate thICkness: 0.55mm

Outer copper thickness 1 OZ

Inner layer copper thickness H OZ

Minimum aperture: 0.2mm

Minimum line width/line spacing: 3mil

Surface Treatment: Immersion Gold

Product use: Leica CAMera

Process difficulties: strict impedance matching requirements

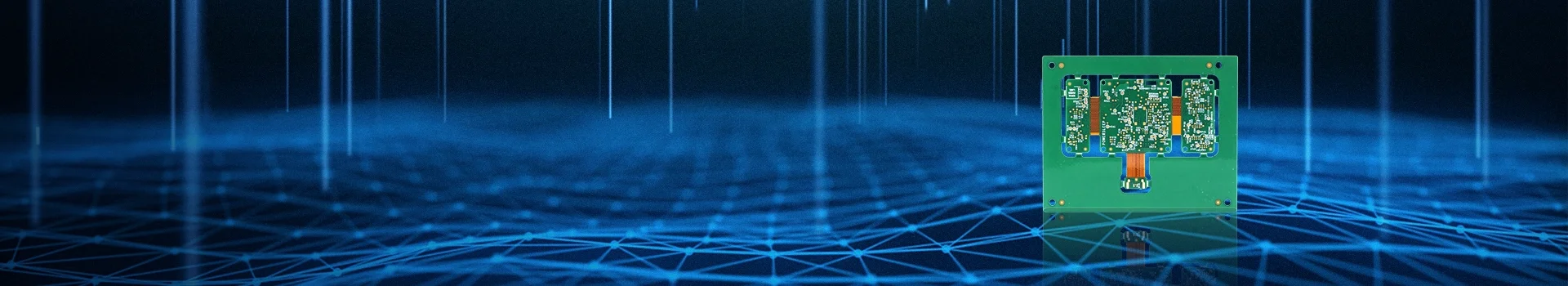

A four-layer composite rigid flex circuit has four conductive copper layers. TypICally, four layers have two flexible layers and two rigid layers.

Flexible printed circuit boards are now mainly used in the electronics industry. As one of the leading manufacturers of these boards, kingford offers 4-layer flexible printed circuit boards. These boards are used in a variety of industrial applications, including power, medical devices, automotive components, and industrial control equipment.

These printed circuit boards have 4 conductive layers and are made of polyimide instead of FR4. As a thermally stable material, polyimide can withstand extreme heat when used in high temperature applications. The flexibility provided by polyimide makes surface mounting easier than rigid boards, helping to SIMplify designs. This polyimide also helps create complex designs that would otherwise be impossible with rigid printed circuit boards. Additionally, this material helps reduce the overall weight of the PCB.

kingford provides 6-layer printed circuit boards in various specifications, such as component pitch/width 4/3 MIL, surface treatment thickness 0.2mm, board thickness 0.5mm~3.0mm (0.02"~0.12"), maximum board size 18"x24" . While Immersion Gold is the most popular choice for finishing, we also offer options such as HASL and OSP. All of these surface treatments help improve the performance of these boards under stressful conditions.

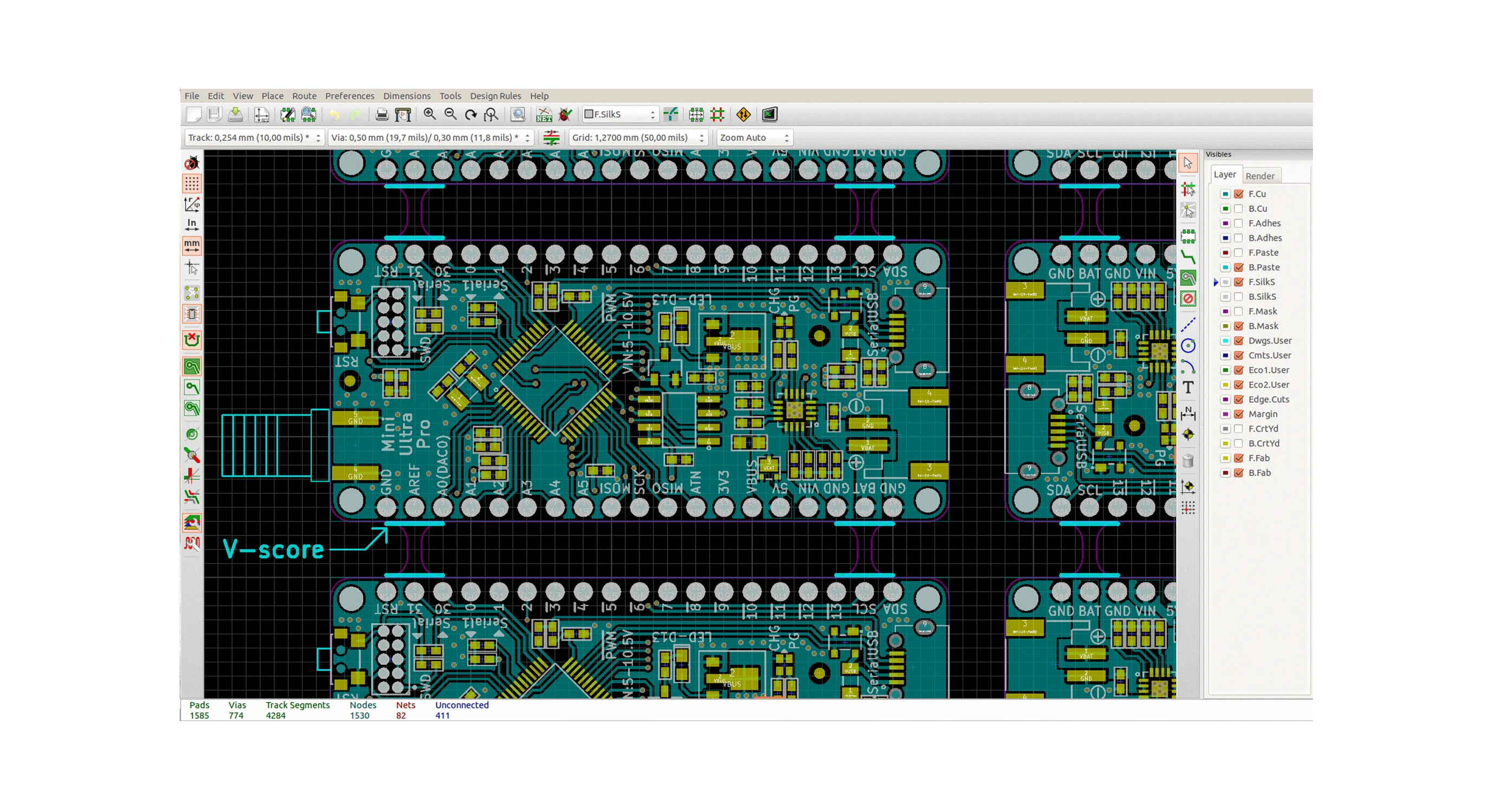

Copper thickness is one of the important aspects of PCB design. The current-carrying capacity of the PCB is entirely dependent on this thickness. That's why we offer a variety of copper thicknesses to choose from. This 6-layer PCB is available in copper thicknesses ranging from 0.5 OZ, 1.0 OZ, 2.0 OZ, 3.0 OZ to 6 OZ. Contouring is performed using V-cut, stamping and routing. These boards are available in popular soldermask colors including blue, green, white and red. We can also offer a special photoimageable solder resist for circuit boards - Taiyo PSR4000 White. PCBs can use any of these silkscreen colors - white and black.

kingford is popular for developing flexible circuit boards with the thinnest substrates. These substrates help reduce weight and improve the heat dissipation capabilities of these boards. Additionally, we can create PCBs with low interconnect points, which help reduce the chance of system failure and increase its reliability. Our extensive industry experience and the accessibility of state-of-the-art equipment in our factories allow us to manufacture complex circuit boards with extremely thin substrates with minimal turnaround time. These thin substrates help reduce package size and weight—a major advantage for the electronics industry.

Name: Four-layer rigid-flex board

Structure: 1R+2F+1R

Layers: 4L

Plate thICkness: 0.55mm

Outer copper thickness 1 OZ

Inner layer copper thickness H OZ

Minimum aperture: 0.2mm

Minimum line width/line spacing: 3mil

Surface Treatment: Immersion Gold

Product use: Leica CAMera

Process difficulties: strict impedance matching requirements

- Previous:TWS Earphone Rigid Flex PCBs

- Next:12-layer Rigid Flex PCB Board