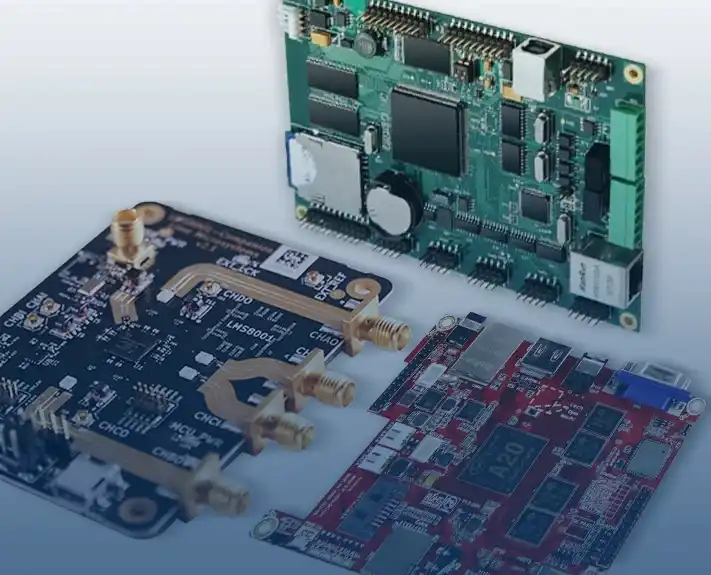

Benefit from building your printed circuit board (PCB) and assembly in a PCB assembly manufacturer. With years of experience in electronic PCB assembly, kingford provides one-stop solutions for PCB manufacturing and PCB assembly services worldwide. Our advanced capabilities allow us to manufacture in small or large quantities with customer-specific prototypes, and we can undertake high-quality printed circuit board assembly at favorable prices and on flexible terms.

Importance of Kingford PCB Manufacturing Services

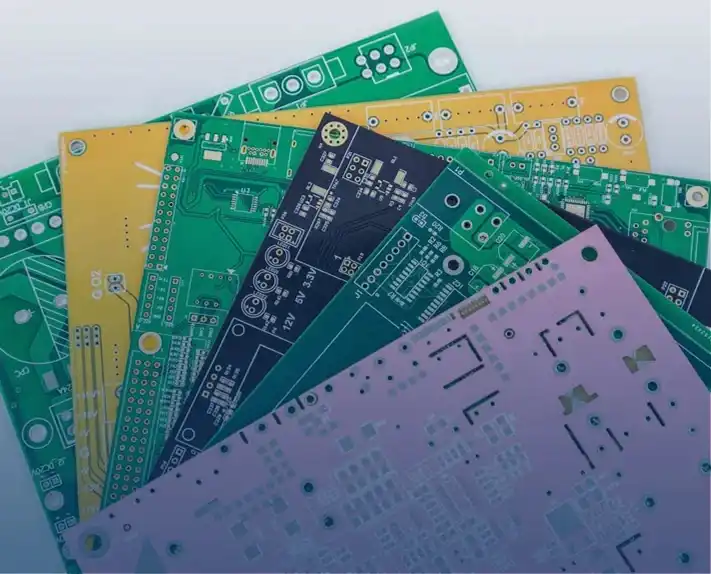

First, companies chose to quickly turn to PCB services to keep up with the latest market trends in PCB and the growing competition in the industry. Critical projects with short lead times mean that companies need to find reliable and professional PCB manufacturing companies with the latest technology and precise mechanisms. Whether it's a turnkey project or a commissioned project, the leading Fast Turn PCB service provider will allow you to benefit from a wide range of service packages depending on the quality of the PCB, size, type of circuits and tools required, and time to complete your project. Quick turn PCB assemblies come in different shapes, sizes and designs such as round, hexagonal, rectangular, etc.

Importance of Prototype PCB Manufacturing Services

PCB prototyping plays a vital role in determining the final design and creation of a printed circuit board. A PCB prototype is just a manufactured PCB made by combining all the vague requirements. This is to check and check the functionality and capability of the final PCB assembly that needs to be manufactured to meet current mechanical and electrical applications. Prototypes are a testing ground for meeting these needs. These prototype PCBs have all the features and properties expected of the final finished PCB. The prototyping stage involves corrections, corrections, additions or omissions of all features (where required) to ensure that the final PCB assembly is free of technical or mechanical flaws.