Industrial control SMT chip processing

Name: Industrial control SMT chip processing

Number of SMT lines: 7high-speed SMT patch supporting production lines

SMT daily production capacity: more than 15 million points

Testing Equipment: X-RAY Tester, First Piece Tester, AOI Automatic Optical Tester, ICT Tester, BGA Rework Station

Placement speed: CHIP component placement speed (at best conditions) 0.036 S/piece

The smallest package that can be attached: 0201, the accuracy can reach ±0.04mm

Minimum device accuracy: PLCC, QFP, BGA, CSP and other devices can be mounted, with a pin pitch of ±0.04mm

IC type patch accuracy: It has a high level for mounting ultra-thin PCB boards, flexible PCB boards, gold fingers, etc. It can be mounted/inserted/mixed with TFT display driver boards, mobile phone motherboards, battery protection circuits and other difficult products

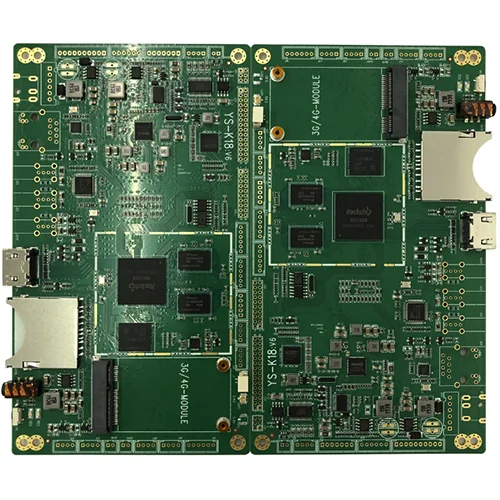

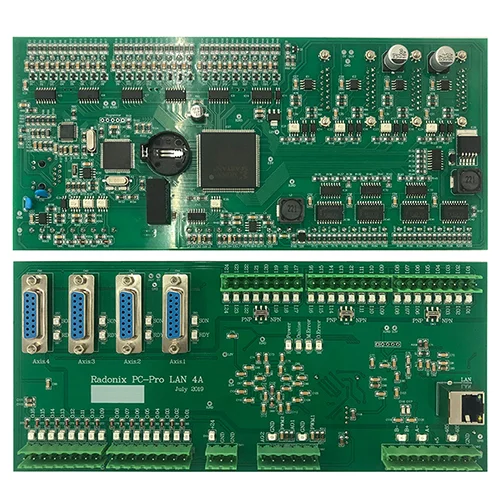

Industrial control product PCB: a circuit board in electrical equipment that controls the normal operation of equipment

1. Special or general circuit board for industrial control, the bottom circuit is completed, and IO is reserved. After purchasing the industrial control circuit board, connect the input and output ports reserved on the circuit board to the user's own equipment, such as a motor. Solenoid valve, sensor to complete the function you want to complete.

2. There are special boards and general boards. A dedicated circuit board is a board specially designed for a certain function, such as a temperature control circuit board. After purchase, the input port is connected to a thermocouple, and the output port is connected to a heating contactor or solid state relay to control the heating device to complete temperature control and current flow. Control panels, motion control panels, etc.

3. The universal control board, most of which can be programmed, through the user's own secondary development, completes specific functions, and has a wide range of uses. For example, PLC is a general industrial control board. After the user writes the program and compiles the input, various functions can be completed. Digital input, analog input port, high-speed counter port, digital output port, analog output port, and some also have communication functions.

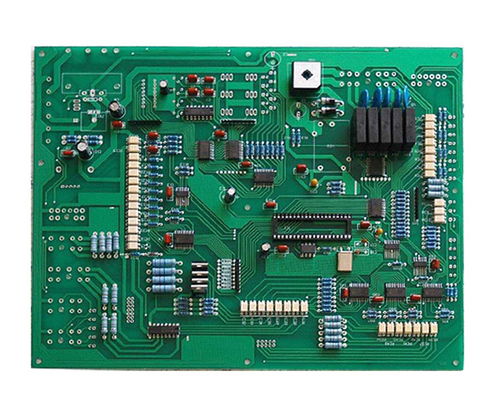

Nowadays, all kinds of electronic products are pursuing miniaturization. The perforated components in the past can no longer meet the current process requirements. Therefore, SMT chip processing technology has emerged. The SMT chip processing technology not only realizes the integrity of product functions but also makes products precise. Miniaturization is currently the most popular technology and process in the electronics assembly industry.

Nowadays, all kinds of electronic products are pursuing miniaturization. The perforated components in the past can no longer meet the current process requirements. Therefore, SMT chip processing technology has emerged. The SMT chip processing technology not only realizes the integrity of product functions but also makes products precise. Miniaturization is currently the most popular technology and process in the electronics assembly industry. So do you know what is SMT patch processing? The following editor of Jingbang circuit board manufacturer will introduce it in detail for you:

Electronic products realize different functions by adding various electronic components such as capacitors and resistors on the PCB board, and these components need to be stably mounted on the PCB, and various SMT chip processing is required. Process for processing and assembly.

SMT chip processing is a kind of non-lead or short-lead surface mount components, referred to as SMC or SMD, Chinese called chip components, installed on the surface of the printed circuit board or other substrates, through reflow soldering or The circuit assembly and connection technology of soldering assembly by dip soldering and other methods.

The basic components of SMT process are: solder paste printing --> parts mounting --> reflow soldering --> AOI optical inspection --> maintenance --> sub-board.

Advantages of SMT chip processing: high density, high reliability, miniaturization, low cost, and production automation of electronic product assembly are realized.

Name: Industrial control SMT chip processing

Number of SMT lines: 7high-speed SMT patch supporting production lines

SMT daily production capacity: more than 15 million points

Testing Equipment: X-RAY Tester, First Piece Tester, AOI Automatic Optical Tester, ICT Tester, BGA Rework Station

Placement speed: CHIP component placement speed (at best conditions) 0.036 S/piece

The smallest package that can be attached: 0201, the accuracy can reach ±0.04mm

Minimum device accuracy: PLCC, QFP, BGA, CSP and other devices can be mounted, with a pin pitch of ±0.04mm

IC type patch accuracy: It has a high level for mounting ultra-thin PCB boards, flexible PCB boards, gold fingers, etc. It can be mounted/inserted/mixed with TFT display driver boards, mobile phone motherboards, battery protection circuits and other difficult products

- Previous:Control motherboard SMT assembly

- Next:No