Industrial Control Through Hole PCB Assembly

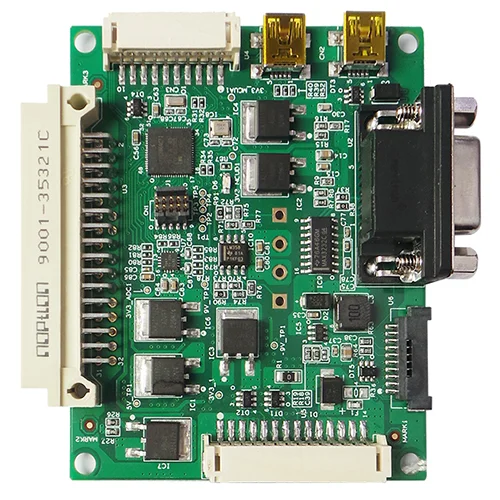

Name: Industrial Control Through Hole PCB Assembly

Substrate: FR-4/CEM-1/CEM-3/Polyimild/PTFE/Rogers

Copper Thickness: 1/3OZ- 6OZ

Plate thickness: 0.21-6.0mm

minute. Hole size: 0.20mm

minute. Line width: 4 million

minute. Line spacing: 0.075 mm

Surface treatment: spray tin/gold drill/OSP/lead-free spray tin

Board size: minimum 10*15mm, maximum 508*889mm

Product Type: OEM&ODM

PCB standard: IPC-A-610 D/IPC-III standard

Certificate: ISO9001/ CE//TUV/ ROHS

Warranty: 1 year

Service: One-stop turnkey service

Electronic testing: 100%

Logistics: Air/Sea

Industrial Automation Control

Industrial control refers to industrial automation control, which is mainly realized by the combination of electronic, electrical, mechanical and software. That is industrial control, or factory automation control. It mainly refers to the use of computer technology, microelectronic technology, and electrical means to make the production and manufacturing process of the factory more automated, efficient, precise, and controllable and visible.

Industrial control refers to industrial automation control. The main structure is composed of all-steel chassis, passive backplane, industrial power supply, CPU card and other accessories. Next, briefly introduce the advantages and disadvantages of industrial computer.

Advantages of industrial computer

1. The chassis adopts steel structure, which has high anti-magnetic, dust-proof and impact-proof capabilities.

2. There is a special bottom plate in the chassis, and there are PCI and ISA slots on the bottom plate.

3. There is a special power supply in the chassis, and the power supply has strong anti-interference ability.

4. It is required to have the ability to work continuously for a long time.

5. Generally, a standard chassis that is easy to install is used.

Disadvantages of industrial computer

1. The configured hard disk capacity is small

2. Low data security;

3. Small storage options.

4. The price is higher.

We support Industrial Control Through Hole PCB Assembly business, Kingford is a professional one-stop PCBA service factory, Welcome to inquiry.

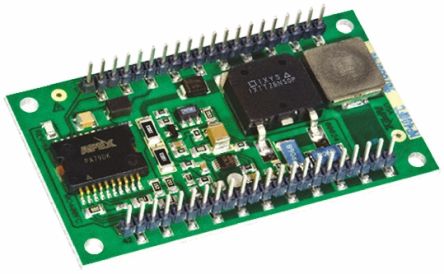

Name: Industrial Control Through Hole PCB Assembly

Substrate: FR-4/CEM-1/CEM-3/Polyimild/PTFE/Rogers

Copper Thickness: 1/3OZ- 6OZ

Plate thickness: 0.21-6.0mm

minute. Hole size: 0.20mm

minute. Line width: 4 million

minute. Line spacing: 0.075 mm

Surface treatment: spray tin/gold drill/OSP/lead-free spray tin

Board size: minimum 10*15mm, maximum 508*889mm

Product Type: OEM&ODM

PCB standard: IPC-A-610 D/IPC-III standard

Certificate: ISO9001/ CE//TUV/ ROHS

Warranty: 1 year

Service: One-stop turnkey service

Electronic testing: 100%

Logistics: Air/Sea