In-vehicle communication system PCB Assembly

Name: In-vehicle communication system Turnkey PCB Assembly

Number of SMT lines: 7 high-speed SMT patch supporting production lines

SMT daily production capacity: more than 30 million points

Testing Equipment: X-RAY Tester, First Piece Tester, AOI Automatic Optical Tester, ICT Tester, BGA Rework Station

Placement speed: CHIP component placement speed (at best conditions) 0.036 S/piece

The smallest package that can be attached: 0201, the accuracy can reach ±0.04mm

Minimum device accuracy: PLCC, QFP, BGA, CSP and other devices can be mounted, and the pin spacing can reach ±0.04mm

IC type patch accuracy: it has a high level for mounting ultra-thin PCB boards, flexible PCB boards, gold fingers, etc. Can be mounted/inserted/mixed TFT display driver board, mobile phone motherboard, battery protection circuit and other difficult products

A vehicle communication system is a computer network in which vehicles and roadside units are communication nodes, providing information to each other, such as safety warnings and traffic information. They can effectively avoid accidents and traffic jams. Both types of nodes are dedicated short-range communications (DSRC) devices. DSRC operates in the 5.9 GHz band with a bandwidth of 75 MHz and a range of approximately 300 meters (980 feet). [1] In-vehicle communications are often developed as part of an Intelligent Transportation System (ITS).

We provide In-vehicle communication system PCB Assembly, Turnkey PCB Assembly services. Kingford is your one-stop Turnkey PCB Assembly company.

Improve the control integration of the whole vehicle, reduce the electric wiring harness of the body, improve the signal transmission accuracy, and facilitate maintenance. The in-vehicle network is an early communication between the internal sensors, controls and actuators of the car, which is connected into a complex network structure by means of point-to-point connections.

With the increasing complexity of the electronic control system and the increasing requirements for the communication capabilities between the electronic control units of the car's internal control functions, the use of point-to-point links will increase the number of wiring harnesses in the car, so considering the reliability, safety and weight of internal communication. All aspects have brought great troubles to the design and manufacture of automobiles. Therefore, in order to reduce in-vehicle connections to achieve data sharing and rapid exchange, while improving reliability, etc., on the rapidly developing computer network, the automotive electronic network system with basic structures such as CAN, LAN, LIN, and MOST, that is, the in-vehicle network.

The intelligent function of the vehicle's information transmission network system can directly display various faults generated by the system, and convert the detected faults into codes and store them for calling during maintenance. Because the information transmission network system can provide a general diagnostic interface for fault diagnosis, it provides great convenience for maintenance personnel to use the multi-function tester to test and diagnose the data stored in the electronic control unit.

The vehicle network system refers to the connection of numerous control modules or (nodes) in the vehicle by means of communication media such as twisted pair, coaxial cable or optical fiber, so that several sensors, actuators and electronic control units ECU share a common data Channels share transmission channels and data under the management of the network controller through a certain communication protocol. The in-vehicle network system reduces the use of wire harnesses, improves the flexibility of the system, and can realize system function changes and data sharing through the system software, and also improves the ability to diagnose system faults. For example, the in-vehicle network can transmit the driving status parameters of the car to the display screen to improve driving safety.

We provide In-vehicle communication system PCB Assembly, Turnkey PCB Assembly services. Kingford is your one-stop Turnkey PCB Assembly company.

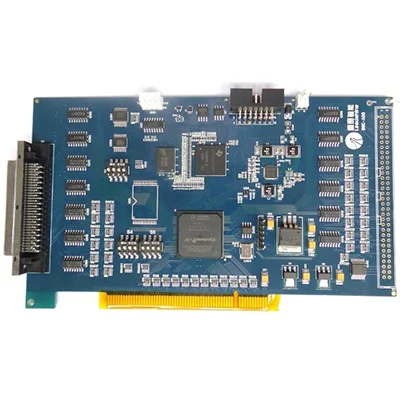

Name: In-vehicle communication system Turnkey PCB Assembly

Number of SMT lines: 7 high-speed SMT patch supporting production lines

SMT daily production capacity: more than 30 million points

Testing Equipment: X-RAY Tester, First Piece Tester, AOI Automatic Optical Tester, ICT Tester, BGA Rework Station

Placement speed: CHIP component placement speed (at best conditions) 0.036 S/piece

The smallest package that can be attached: 0201, the accuracy can reach ±0.04mm

Minimum device accuracy: PLCC, QFP, BGA, CSP and other devices can be mounted, and the pin spacing can reach ±0.04mm

IC type patch accuracy: it has a high level for mounting ultra-thin PCB boards, flexible PCB boards, gold fingers, etc. Can be mounted/inserted/mixed TFT display driver board, mobile phone motherboard, battery protection circuit and other difficult products