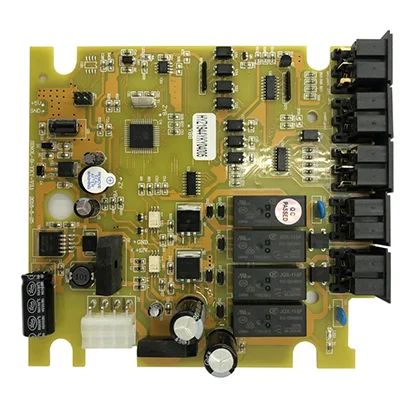

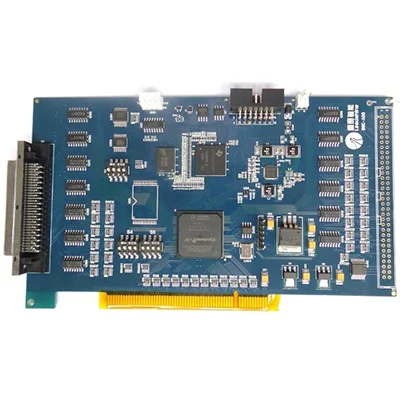

Communication motherboard Turnkey PCB Assembly

Name: Communication motherboard Turnkey PCB Assembly

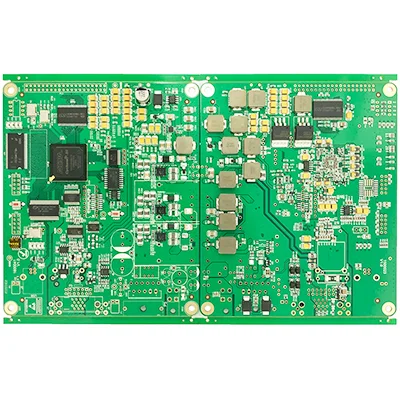

Number of SMT lines: 7 high-speed SMT patch supporting production lines

SMT daily production capacity: more than 30 million points

Testing Equipment: X-RAY Tester, First Piece Tester, AOI Automatic Optical Tester, ICT Tester, BGA Rework Station

Placement speed: CHIP component placement speed (at best conditions) 0.036 S/piece

The smallest package that can be attached: 0201, the accuracy can reach ±0.04mm

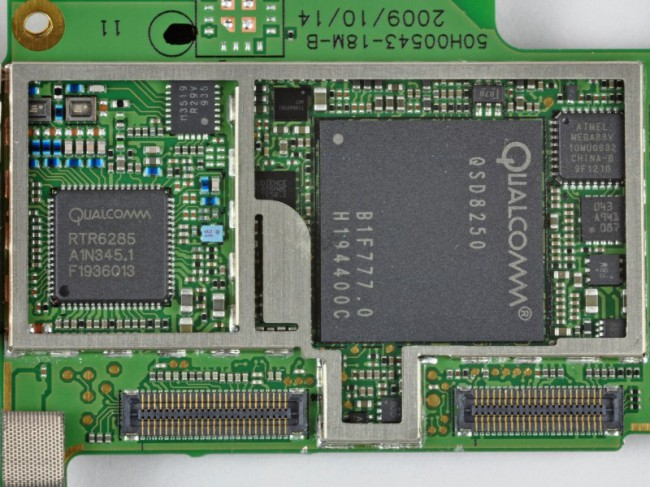

Minimum device accuracy: PLCC, QFP, BGA, CSP and other devices can be mounted, and the pin spacing can reach ±0.04mm

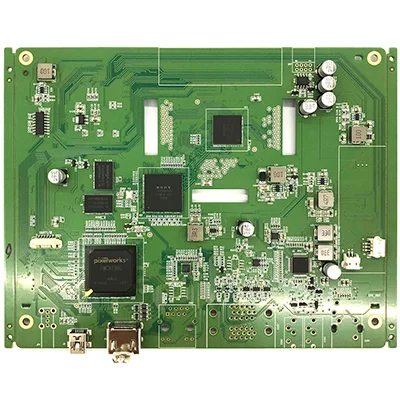

IC type patch accuracy: it has a high level for mounting ultra-thin PCB boards, flexible PCB boards, gold fingers, etc. Can be mounted/inserted/mixed TFT display driver board, mobile phone motherboard, battery protection circuit and other difficult products

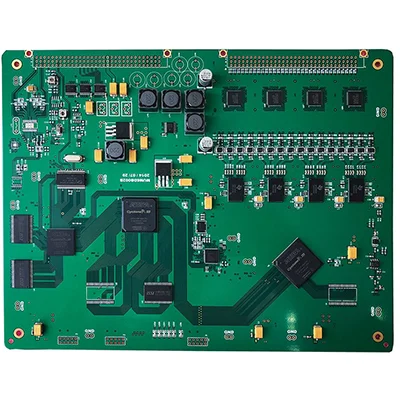

The high-frequency hybrid splint includes a base plate, which is folded and positioned on the first inner wire layer, the first outer wire layer, and the top surface of the solder mask ink layer from bottom to top in order from top to bottom. The positioning circuit layer, the second outer wire layer, the bottom surface of the substrate The second layer of solder resist ink layer, the substrate includes a high-frequency area and an auxiliary area, the auxiliary area is finally fixed, and the high-frequency area inlay should be located in a fixed position. The utility model provides a high-frequency hybrid splint, which is divided into two parts: a high-frequency area and an auxiliary area. Provide mechanical support. The utility model discloses that the high-frequency area is independently arranged, and only the high-frequency area is made of high-frequency materials. Under the condition of satisfying high-frequency signals, the use of high-frequency board materials is minimized and the production cost is reduced.

High Frequency Hybrid Product Classification Layers: 6 Layers Used Board: ro4350b +FR4 Thickness: 1.6mm Size: 210mm*280mm Surface Treatment: Gold-plated Minimum Aperture: 0.25mm Application: Communication Features: High Frequency Mixed Pressure

We provide Communication motherboard Turnkey PCB Assembly, Turnkey PCB Assembly services. Kingford is your one-stop Turnkey PCB Assembly company.

Name: Communication motherboard Turnkey PCB Assembly

Number of SMT lines: 7 high-speed SMT patch supporting production lines

SMT daily production capacity: more than 30 million points

Testing Equipment: X-RAY Tester, First Piece Tester, AOI Automatic Optical Tester, ICT Tester, BGA Rework Station

Placement speed: CHIP component placement speed (at best conditions) 0.036 S/piece

The smallest package that can be attached: 0201, the accuracy can reach ±0.04mm

Minimum device accuracy: PLCC, QFP, BGA, CSP and other devices can be mounted, and the pin spacing can reach ±0.04mm

IC type patch accuracy: it has a high level for mounting ultra-thin PCB boards, flexible PCB boards, gold fingers, etc. Can be mounted/inserted/mixed TFT display driver board, mobile phone motherboard, battery protection circuit and other difficult products