PTFE | PTFE pcb high-frequency circuit board factory explanation

PCB manufacturing, PCB design, PCBA processing manufacturer will explain to you PTFE | PTFE pcb high-frequency circuit board factory

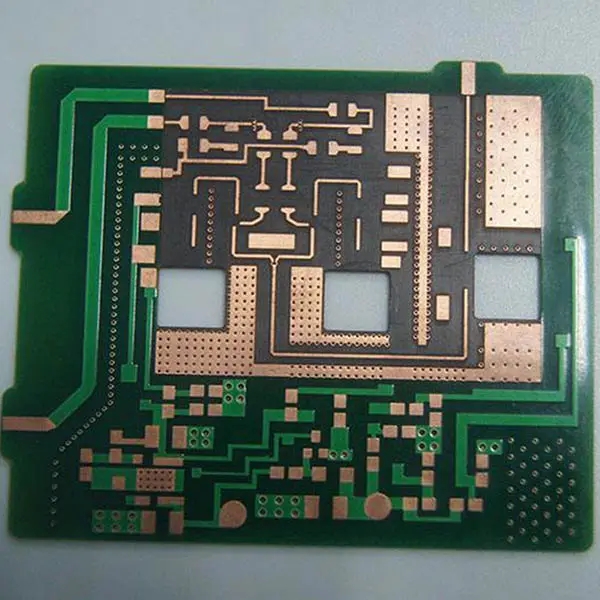

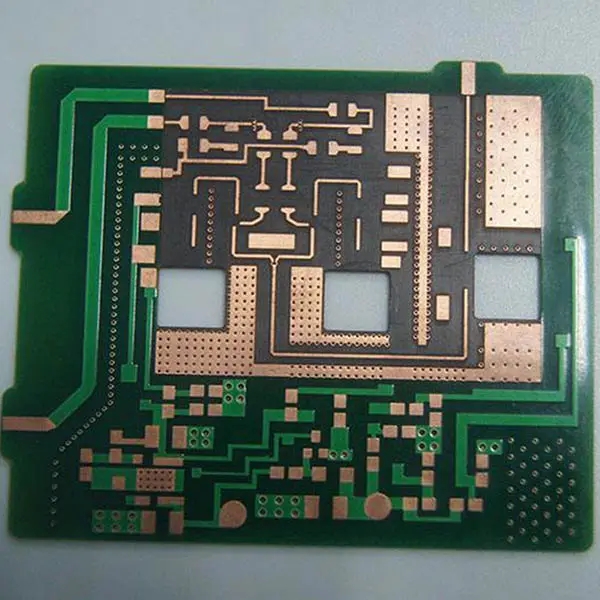

High frequency is the development trend of electronic equipment, especially with the increasing development of wireless networks and satellite communications, information products are moving towards high speed and high frequency, and communication products are moving towards the standardization of voice, video and data for wireless transmission with large capacity and fast speed Therefore, the new generation of products need high frequency boards. Communication products such as satellite systems and mobile phone receiving base stations must use high frequency circuit boards. In the next few years, it is bound to develop rapidly, and high frequency boards will be in great demand.

The basic characteristics of high-frequency plate materials are as follows:

(1) The dielectric constant (Dk) must be small and stable. In general, the smaller the better the signal transmission rate is, the inverse ratio of the square root of the dielectric constant of the material is. High dielectric constant is easy to cause signal transmission delay.

(2) The dielectric loss (Df) must be small, which mainly affects the quality of signal transmission. The smaller the dielectric loss, the smaller the signal loss.

(3) The thermal expansion coefficient shall be consistent with that of copper foil as much as possible, because the inconsistency will cause copper foil separation in cold and hot changes.

(4) Low water absorption and high water absorption will affect the dielectric constant and dielectric loss when affected with moisture.

(5) Other heat resistance, chemical resistance, impact strength and peel strength must also be good.

Advantages of PTFE sheet:

1) High temperature resistance - the operating temperature reaches 250 ℃.

2) Low temperature resistance - good mechanical toughness; The elongation of 5% can be maintained even if the temperature drops to - 196 ℃.

3) Corrosion resistance: It is inert to most chemicals and solvents, and can resist strong acids and alkalis, water and various organic solvents.

4) Weather resistance: it has the best aging life of plastics.

5) High lubrication is the one with the lowest friction coefficient among solid materials.

6) Non adhesion - it is the minimum surface tension in solid materials. It does not adhere to any substance. Its mechanical property has a very small friction coefficient, which is only 1/5 of polyethylene. This is an important feature of perfluorocarbon surface. And because of the extremely low force between fluorine carbon chain molecules, PTFE is not sticky.

7) Toxic free: It is physiologically inert and can be implanted into the body as an artificial blood vessel and organ for a long time without adverse reactions.

8) Good electrical performance - PTFE has low dielectric constant and dielectric loss in a wide frequency range, and high breakdown voltage, volume resistivity and arc resistance.

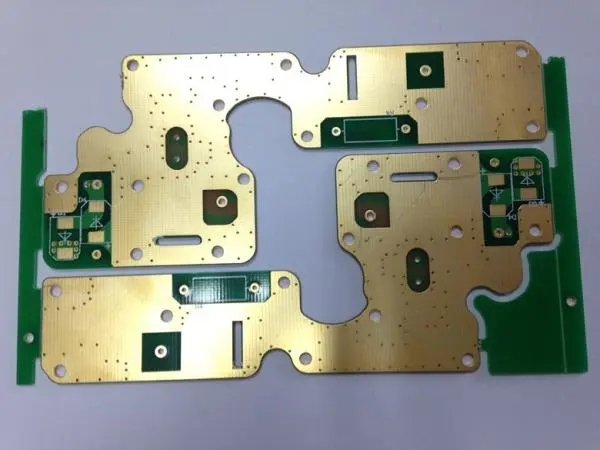

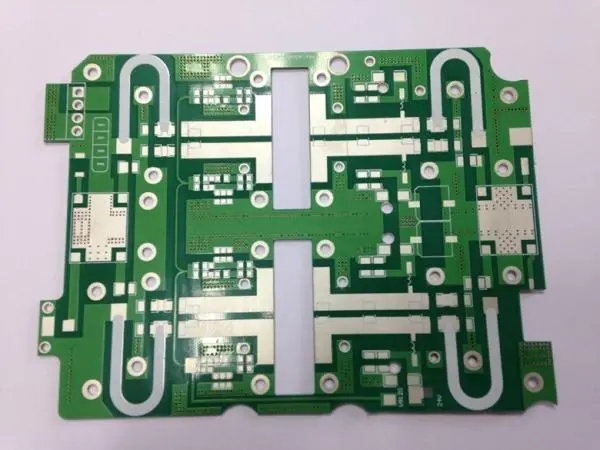

PTFE PCB

Polytetrafluoroethylene plate (also known as tetrafluoroethylene plate, Teflon plate and Teflon plate) is divided into two types: molding and turning. The molding plate is made by molding polytetrafluoroethylene resin at room temperature, sintering and cooling. PTFE turning plate is made of PTFE resin by pressing, sintering and rotary cutting. Its products are widely used and have excellent comprehensive properties: high and low temperature resistance (- 192 ℃ - 260 ℃), corrosion resistance (strong acid, strong alkali, aqua regia, etc.), weather resistance, high insulation, high lubrication, non adhesion, non-toxic and other excellent characteristics.

At the same time, because of these advantages of polytetrafluoroethylene sheet, there are many difficulties in processing, and the processing difficulty will increase a lot. PCB manufacturers, PCB designers and PCBA manufacturers will explain to you about PTFE | PTFE pcb high-frequency circuit board factory.