When we were designing PCB, we attached great importance to the direction and corresponding sequence of bit numbers. We worried that the direction of the screen printing of bit numbers was reversed or the screen printing was not placed correctly, which would affect the error of the patch.

So how much impact does the silk screen position number cross or reverse the order of the silk screen position number have on the patch?

Will incorrect design of silk screen position number affect PCBA patch processing?

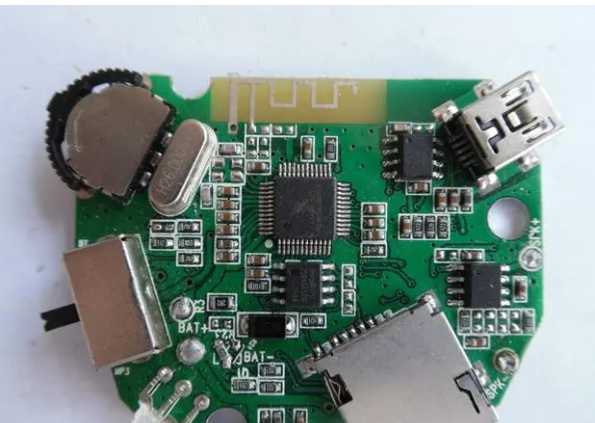

First of all, we can clearly say that the silk screen position number does not determine whether the final patch is correct. A lot of experienced engineers found that a lot of experienced engineers found that delete the bit number silk screen printing, PCBA product patch back and no problem. Generally, the machine patch finds the device and then places the found device in the correct position on the PCB. This involves simple programming, including two points:

1. The pick-up program is to tell the machine where to pick up the parts, what components to pick up, with what packaging components and other pick-up information. The contents include: component name of each step, offset of X, y and Angle t of each step, type of feeder, pick height, drop position, whether to skip, etc.

2. The patch program is to tell the machine where to paste components, the Angle of the patch, the height of the patch and other information. The contents include: component name and description of each step, X, y coordinates and Angle t of each step, patch height whether to correct, patch head number, whether to patch time at the same time, whether to skip steps, etc. The patch also includes the PCB's X and Y coordinate information and local marking, etc.

This means that the machine patch will not find the silk-screen bit number on your PCB at all, but work according to the programming program, and the most important file for programming is the exact coordinate file, so we can understand why you don't need the bit map, but you must need the coordinate file.

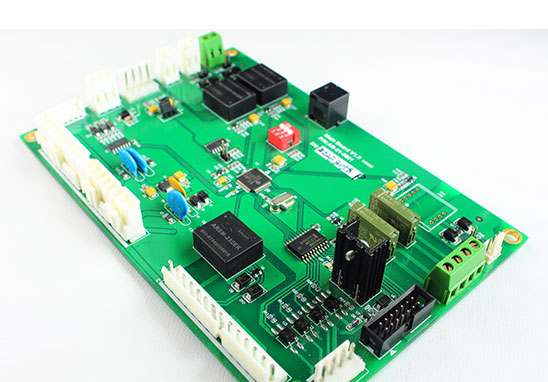

Shenzhen kingford Co., Ltd. specializes in providing integrated PCBA electronic manufacturing services, including PCB design, upstream electronic component procurement to PCB production and processing, SMT patch, DIP plug-in, PCBA testing, finished product assembly and other one-stop services.

The company gives full play to its competitive advantages in scale procurement and quality control, and has signed long-term cooperation agreements with many electronic component manufacturers at home and abroad and around the world to ensure the quality and stable supply of raw materials, and transfer the benefits to customers.

Long-term maintenance of IC, resistance, capacitance, inductance, audion and other components procurement advantages, can greatly save the customer's inventory cost, improve the production turnover efficiency, save time. At present, we provide PCBA processing services to customers in the United States, Britain, Japan, Russia, France, Canada, Australia, Romania, Switzerland and other countries and regions.

We provide PCBA processing services, starting from PCB circuit board production, our own PCB manufacturers (obtained the very strict TS16949 certification of the automotive industry), pay attention to the quality of the circuit board and PCBA quality control system.

With decades of experience in purchasing electronic components, we maintain long-term cooperation with large brands to ensure the original packaging and procurement channels of components. In the process of component packaging, the selection of Qianzhu and Letai solder paste, to ensure the reliability of welding, with automatic printing press, Panasonic high-speed SMT machine, up and down eight temperature zone reflow welding, AOI automatic optical detector, can effectively ensure the reliability and quality of electronic packaging process.

In addition, perfect IPC, IPQC, OQA and other management processes, clear job responsibilities, strict implementation of IPC electronic assembly acceptance standards. For PCBA testing, we have professional engineers to perform 100% batch testing using a variety of test stands, including access, noise, amplitude, signal, temperature, humidity, drop or to perform customer detailed test plans. All efforts are aimed at becoming a refined PCBA processing factory.