Small knowledge base of surface roughness patch adhesive

Glue for 1 square meter patch treatment and its technical requirements:

The glue used in SMT is mainly used for wave soldering technology companies, soil and other surface mount devices of this chip module Glue is used to fix the surface mounted components on the printed circuit board to prevent the components from falling off or shifting under the impact of high temperature wave peaks Generally, epoxy resin heat curing adhesive is used in production instead of acrylic adhesive (UV radiation is required for curing).

Second, the requirements of surface roughness work on patch adhesive:

(1) The glue shall have good thixotropic effect.

(2) No wire drawing.

(3) High wet strength.

(4) No bubbles.

(5) The curing temperature is low and the curing time is short.

(6) It has sufficient curing strength.

(7) Low moisture absorption.

(8) It has good rework characteristics.

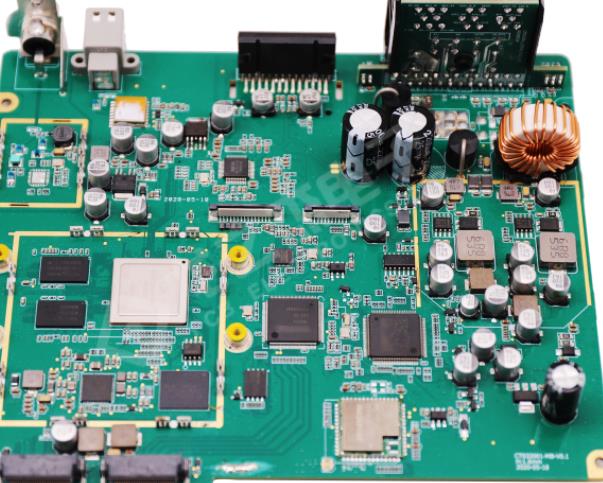

Circuit board

(9) Non toxic.

(10) The color is easy to identify, which is convenient to check the quality of the glue point.

(11) Packaging. The packaging type shall be convenient for the use of the equipment.

3. Process control plays a very important role in dispensing process.

The following process defects are easy to occur in surface roughness production: unqualified glue point size, wire drawing, dipped rubber pad, poor curing strength, and easy to peel off In order to solve these problems, various process parameters should be studied as a whole in order to find solutions to the problems

(1) Size of allocation

According to work experience, the diameter of the glue point shall be half of the pad distance, and the diameter of the repaired glue point shall be 1.5 times of the diameter of the glue point. Through this kind of pipe, it can ensure that there is enough glue to bond the parts and avoid excessive glue impregnating the gasket. The amount of glue to be distributed depends on the length of time the screw pump rotates.

In practice, the rotation time of the pump should be selected according to the production conditions (room temperature, glue viscosity, etc.).

(2) Distribution pressure (back pressure)

The currently used glue applicator uses a screw pump to supply the glue needle, and the hose bears the pressure to ensure that sufficient glue is supplied to the screw pump. Excessive back pressure can easily lead to glue overflow and excessive glue volume. If the pressure is too low, intermittent dispensing, leaks and defects will occur.

The pressure shall be selected according to the glue of the same quality and the working ambient temperature. High ambient temperature will reduce the viscosity of glue and improve its fluidity. At this point, it is necessary to reduce the back pressure to ensure glue supply, and vice versa.

(3) Glue temperature

Generally speaking, the epoxy resin adhesive shall be stored in the freezer at 0-50 ℃ and taken out 1/2 hour before use to make the adhesive fully meet the working temperature. The operating temperature of glue should be 230C-250C. The ambient temperature has a great influence on the viscosity of glue. If the temperature is too low, the bonding point will become smaller and wire drawing will occur.

When the ambient temperature difference is 50 ℃, the dispensing amount will change by 50%. The ambient temperature shall be controlled. At the same time, the ambient temperature should also be guaranteed. Small glue spots are easy to dry and affect the adhesion.

(4) Glue viscosity

The viscosity of glue directly affects the quality of glue. If the viscosity is large, the glue point will become smaller, even wire drawing. If the viscosity is small, the glue point will become larger, and the gasket may bleed. In the distribution process, select reasonable back pressure and distribution speed for glue with different viscosity.

To adjust the above parameters, the SMT processing manufacturer shall follow the point and face method The change of any parameter will affect other aspects At the same time, the occurrence of defects may be caused by many aspects, and the possible factors should be dealt with one by one Troubleshooting after inspection

In production, the parameters should be adjusted according to the actual situation to ensure production quality and improve production efficiency.