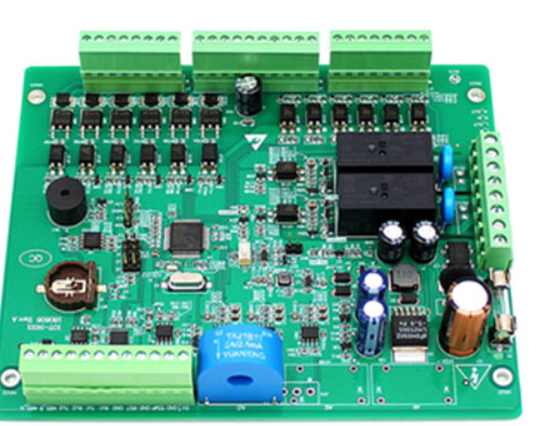

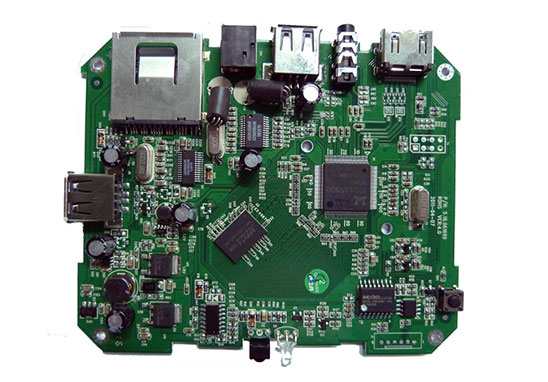

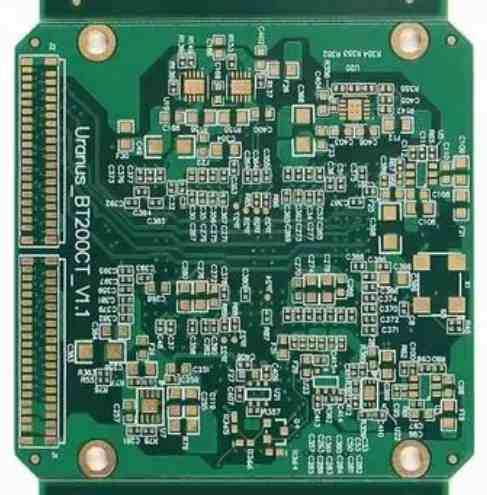

Circuit board design when choosing components of six skills

When selecting circuit board components based on component packaging, the following needs to be considered: component packaging selection. Grounding methods. Virtual component packaging. Verify complete material list data. Sort. Excess gate circuit.