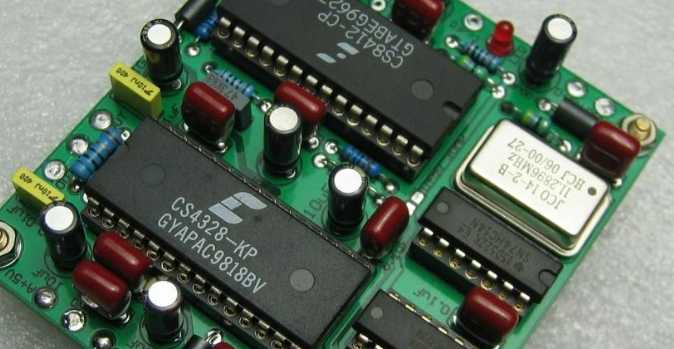

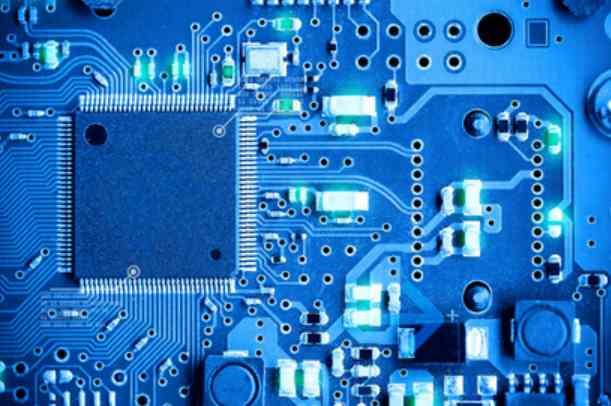

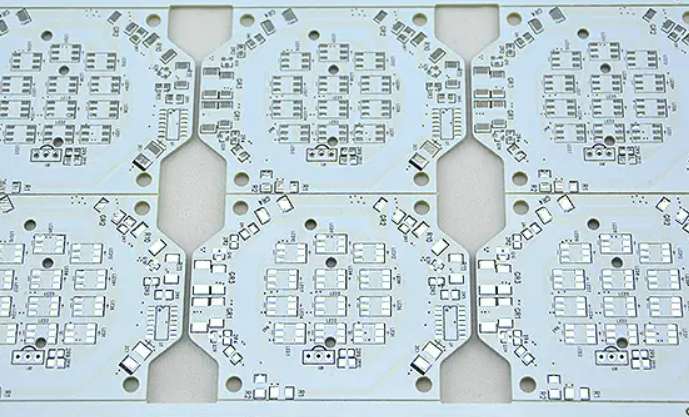

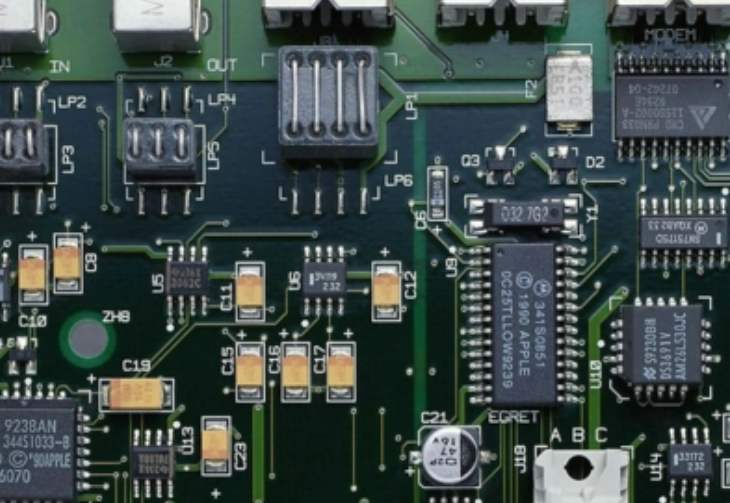

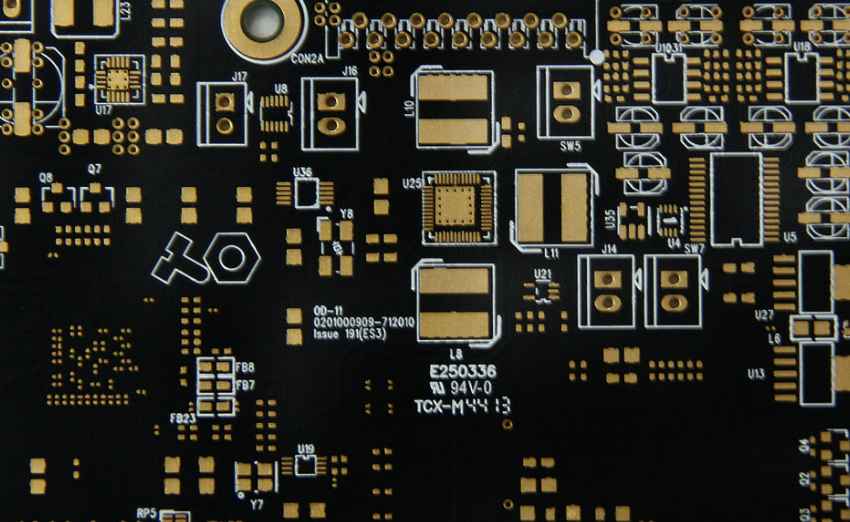

Wiring arrangement and reasonable layout of the components of Fanyi PCB dispatched field engineers

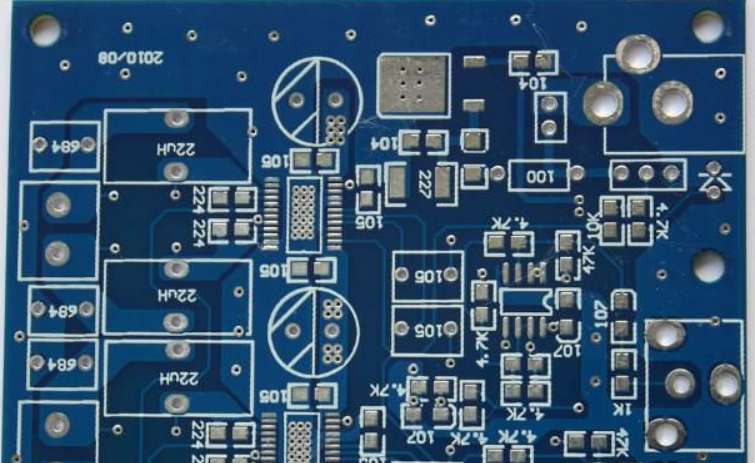

In mixed-signal PCB design, there are special requirements for power wiring and the isolation of analog and digital noise from each other to avoid noise coupling, thus increasing the complexity of layout and wiring.