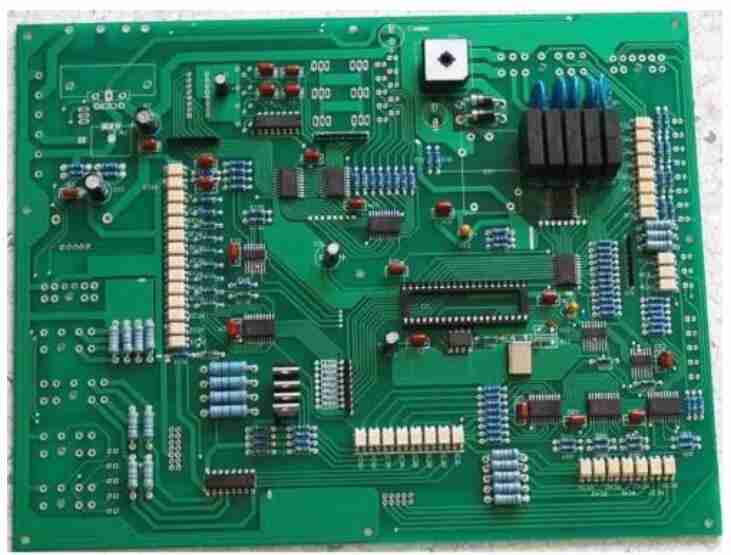

Control PCB cost, these four points you want to look at

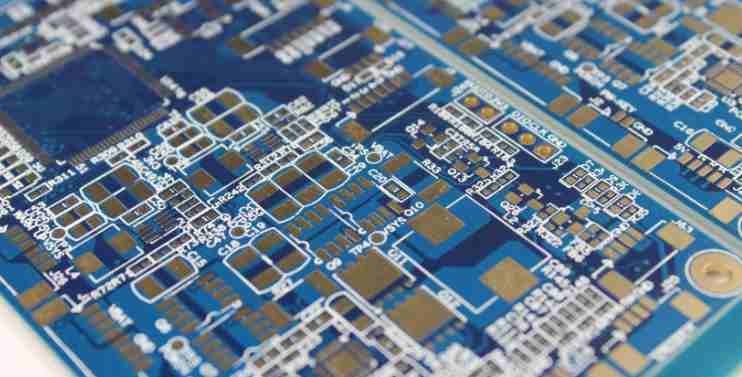

Usually the same area, the more PCB layers, the more expensive the price. The design engineer should use as few layers as possible to complete the PCB design while ensuring the quality of the design signal.