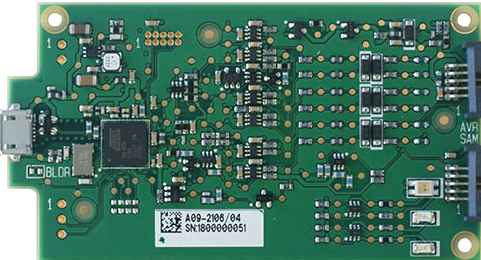

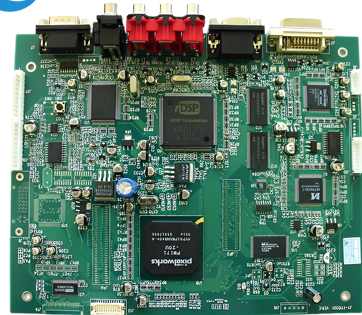

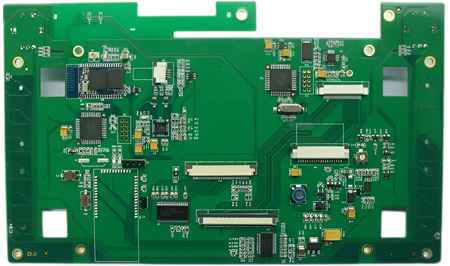

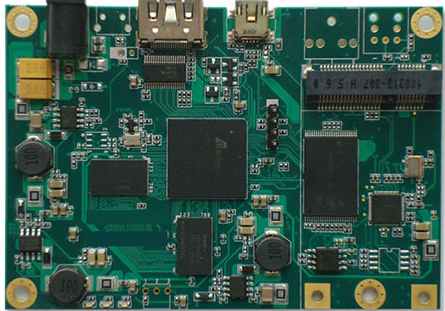

Placement of SMT components on PCB

When SMT components are placed, connectors are placed first, followed by power circuits, sensitive and precision circuits, critical circuit components, and any other required components. You are selecting route priorities based on power level, noise sensi