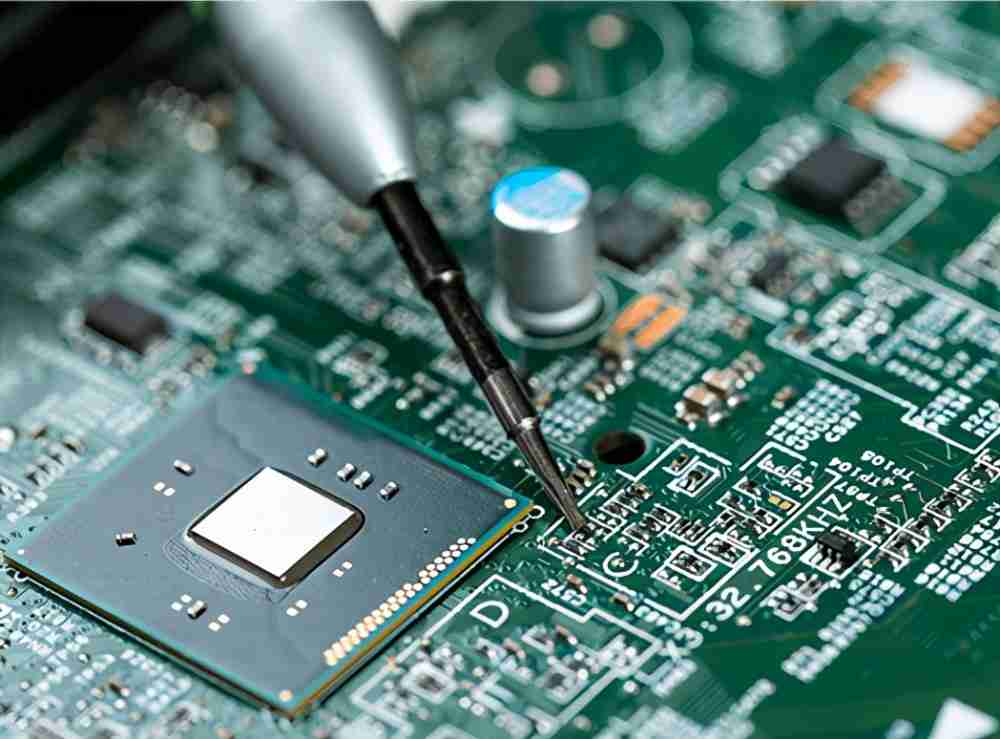

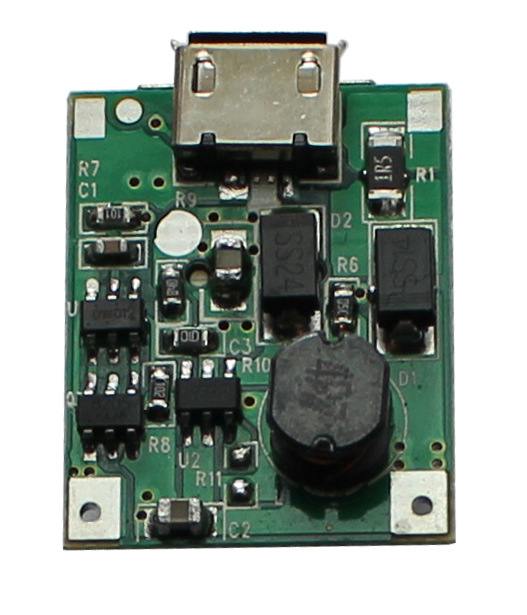

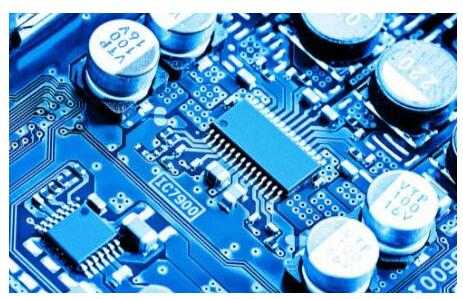

13 years of PCB board copying experience

Rich experience in copying board on the basis of guaranteed success rate, but also can finish the work of copying board faster. High efficiency and high success rate make subroutine electronics highly praised in the industry.