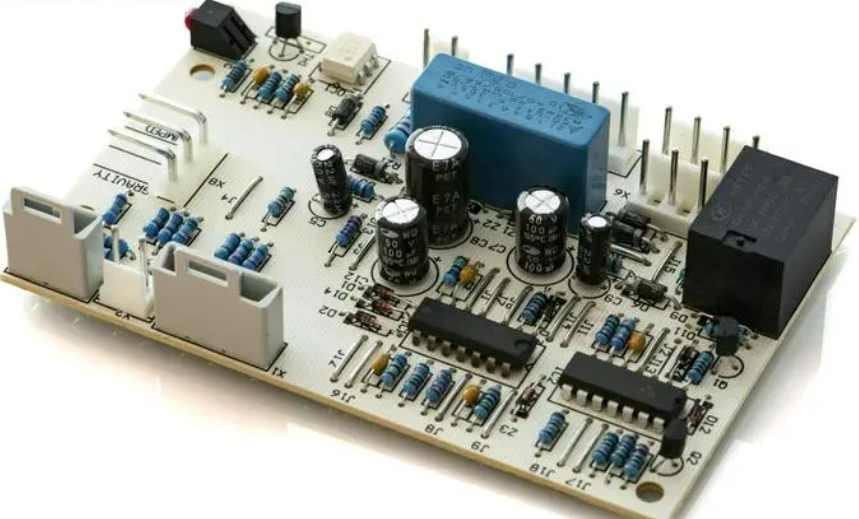

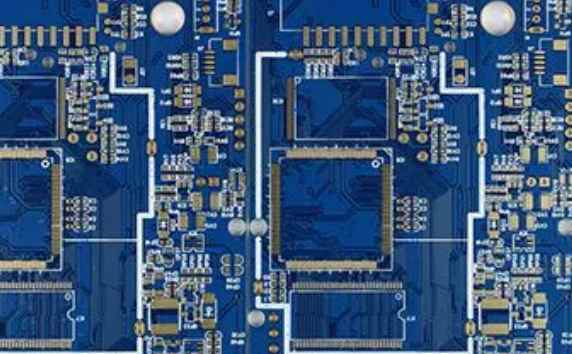

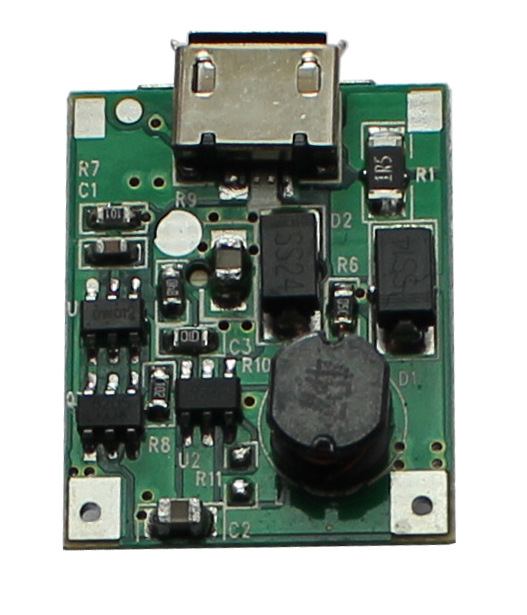

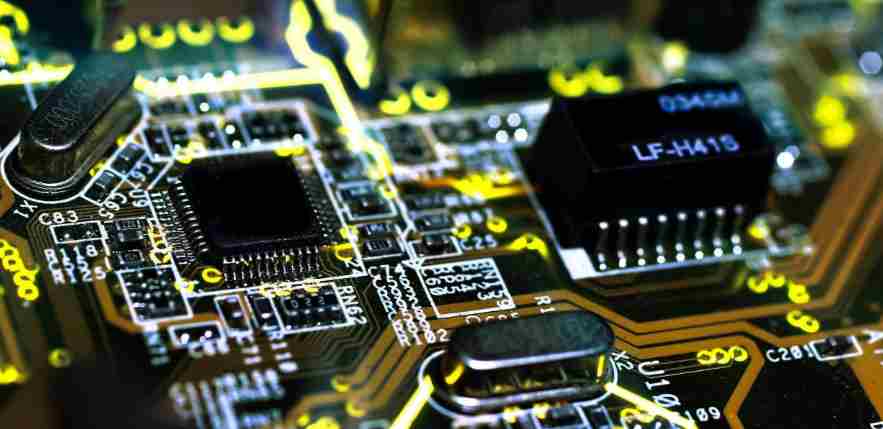

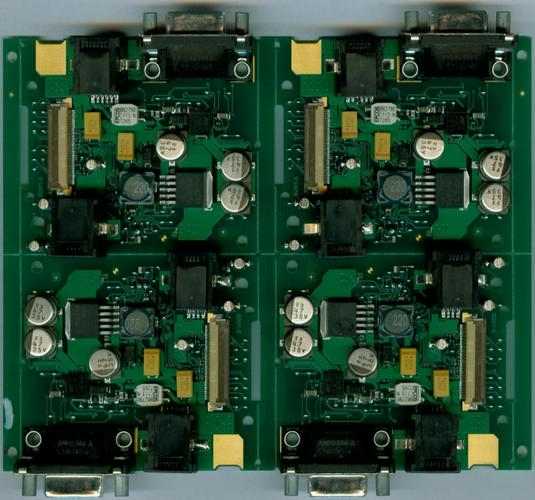

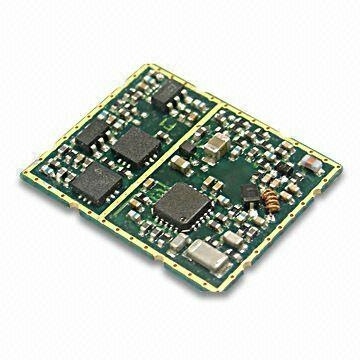

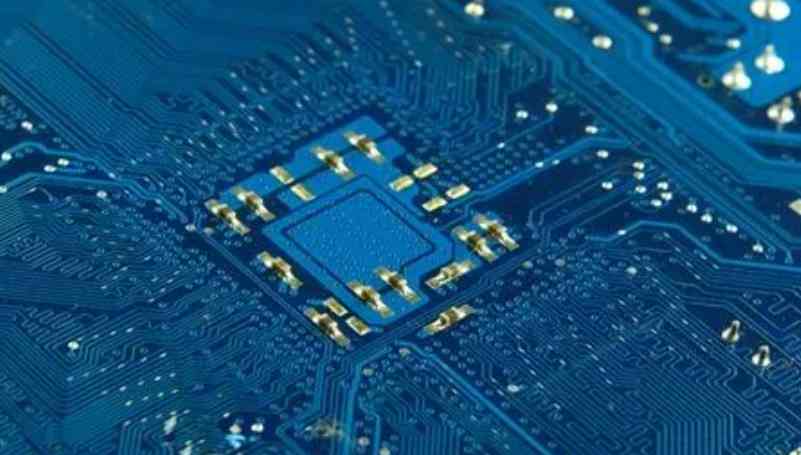

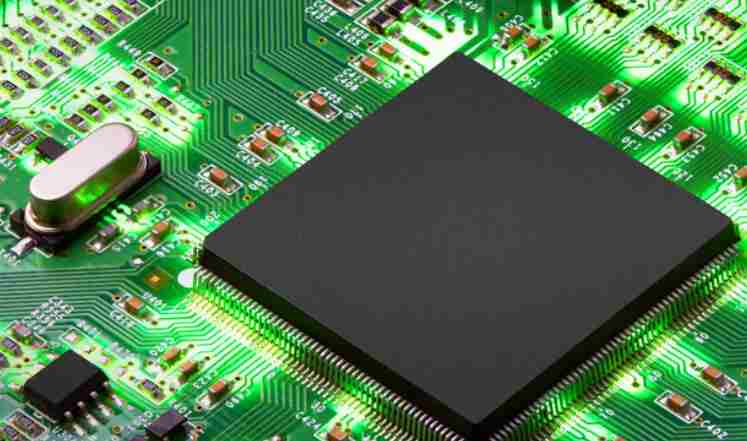

High frequency circuit board wiring precautions

With the wide application of wireless communication technology in various fields, high frequency, high speed and high density have gradually become one of the development trends of modern electronic products.