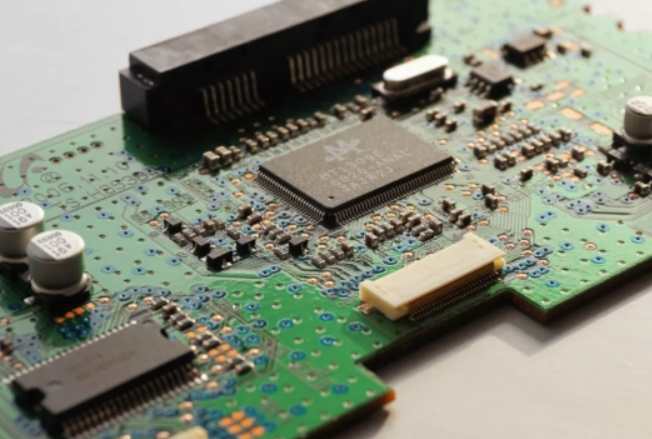

How can PCB boards be prevented from bending and warping due to reflow soldering

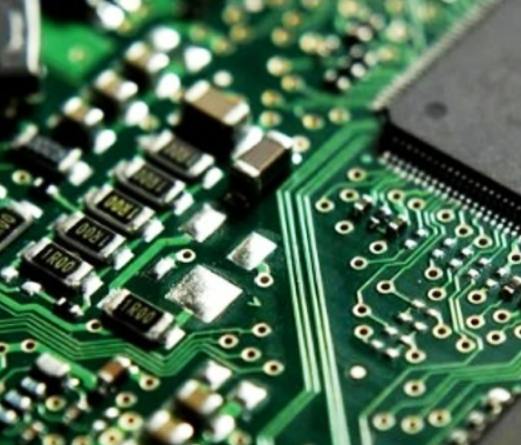

Analysis of PCB deformation causes :1. The uneven area of the copper plane on the circuit board will aggravate the bending and warping of the circuit board. 2. The weight of the PCB board itself may also cause the board to sag and deform.