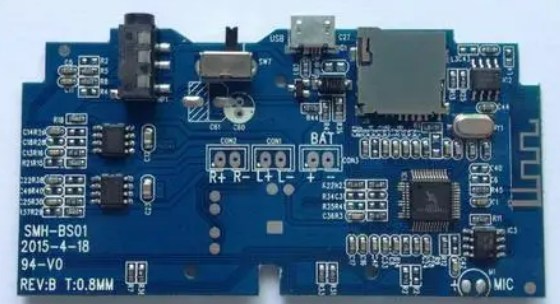

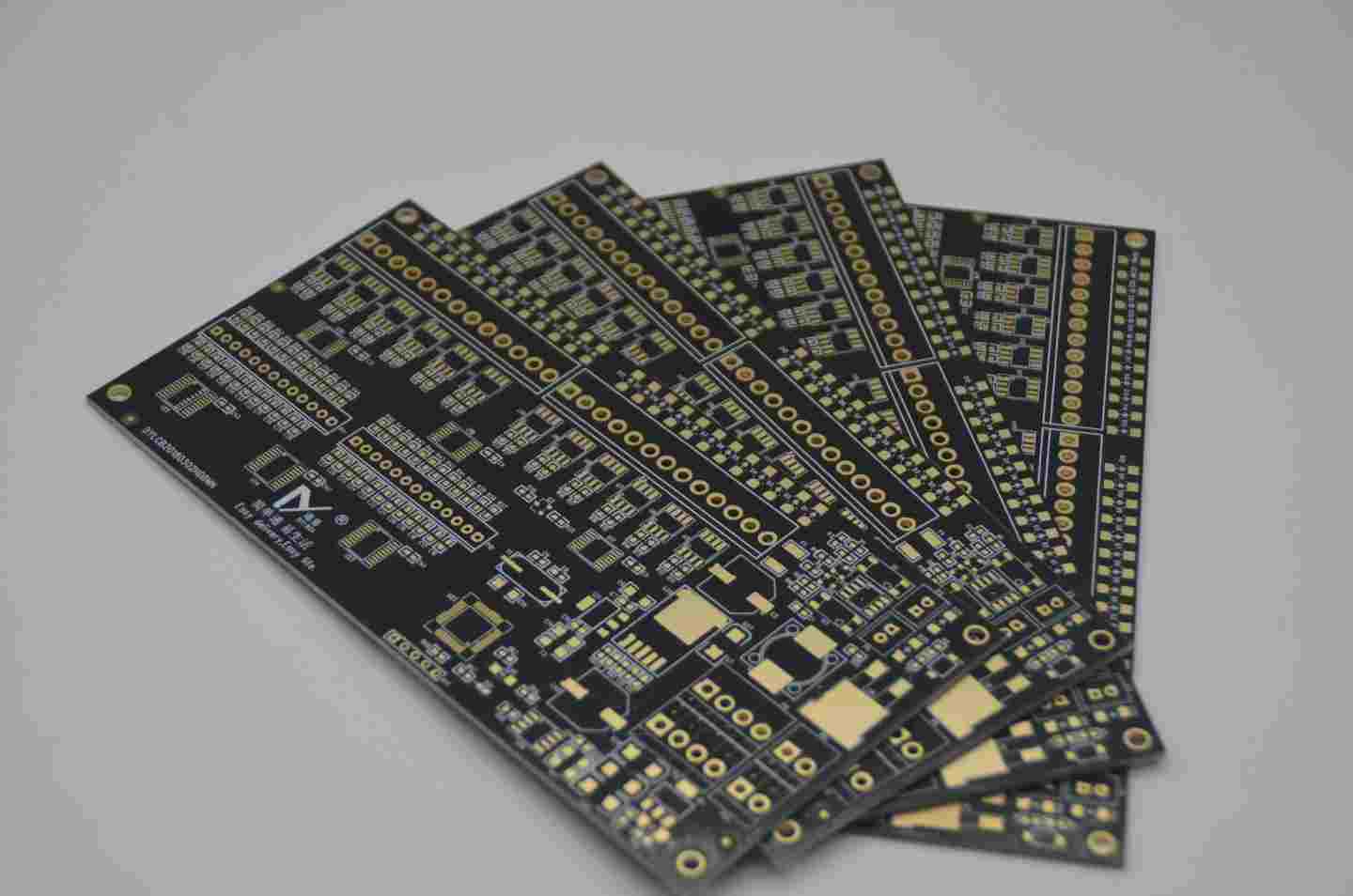

Standard requirements for coating thickness of three anti - paint in PCBA processing

Circuit boards must use the thinnest coating material to provide maximum protection in order to minimize heat retention, additional weight gain and various other problems.