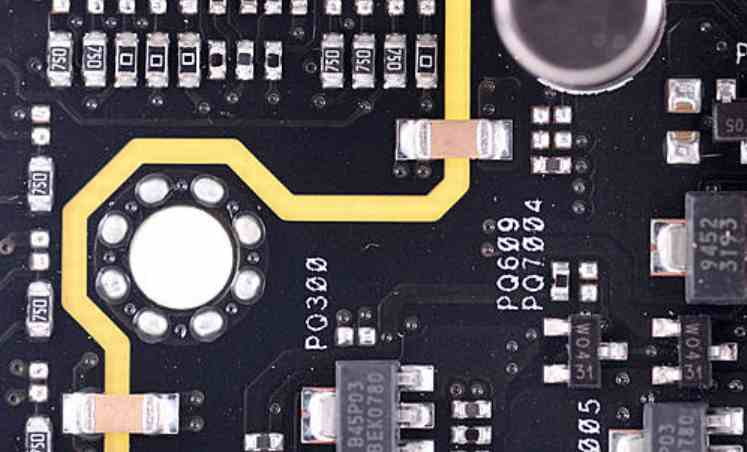

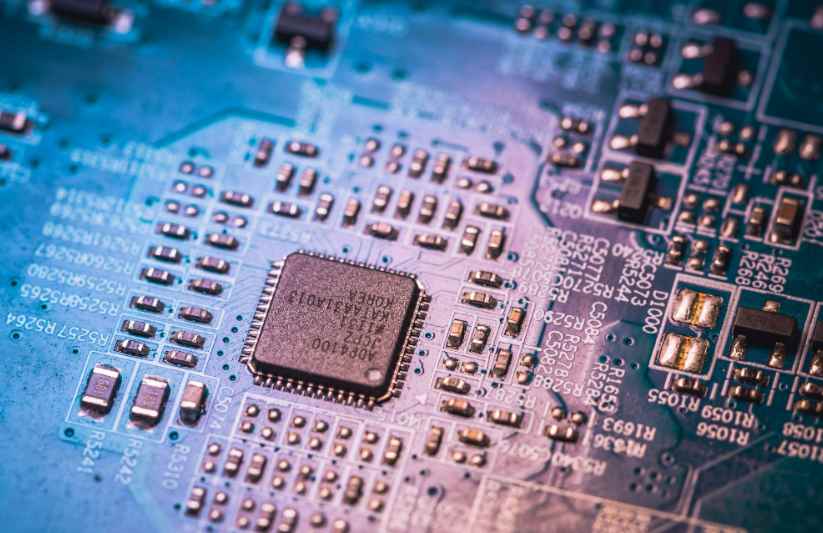

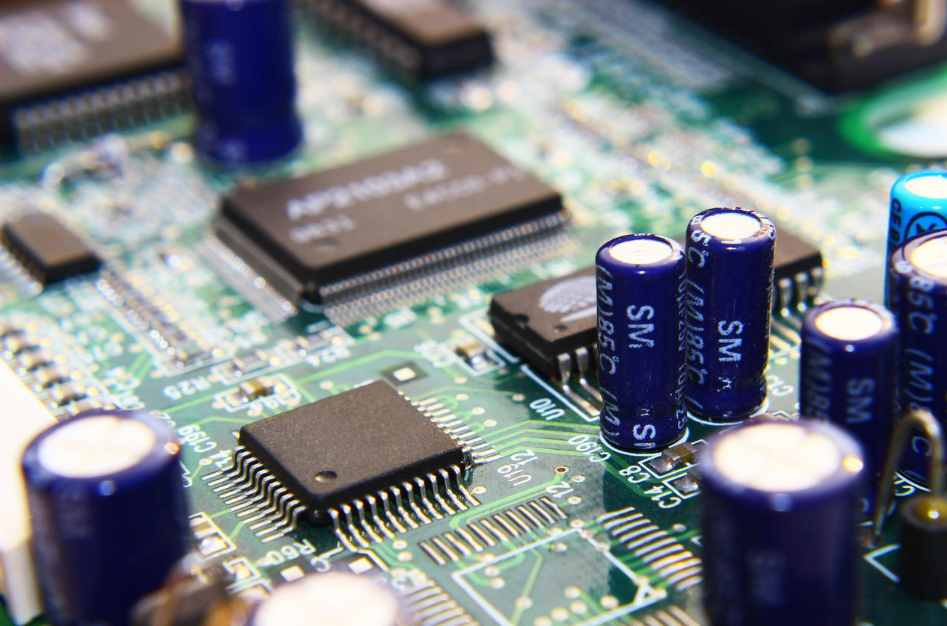

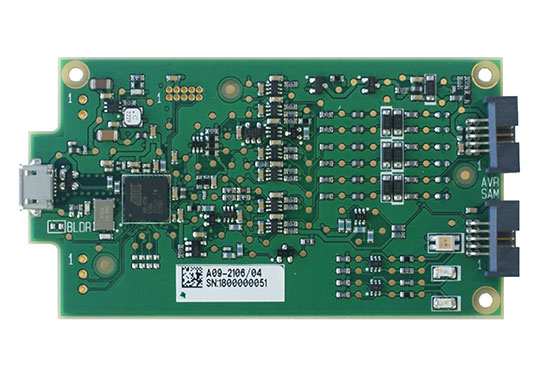

Teach you how to test PCB circuit board is qualified

Electrical testing is a very important link in the PCB board manufacturing process, the purpose is to check whether the PCB board is open and short circuit problem, to ensure that the finished products in line with the customer's electrical performanc