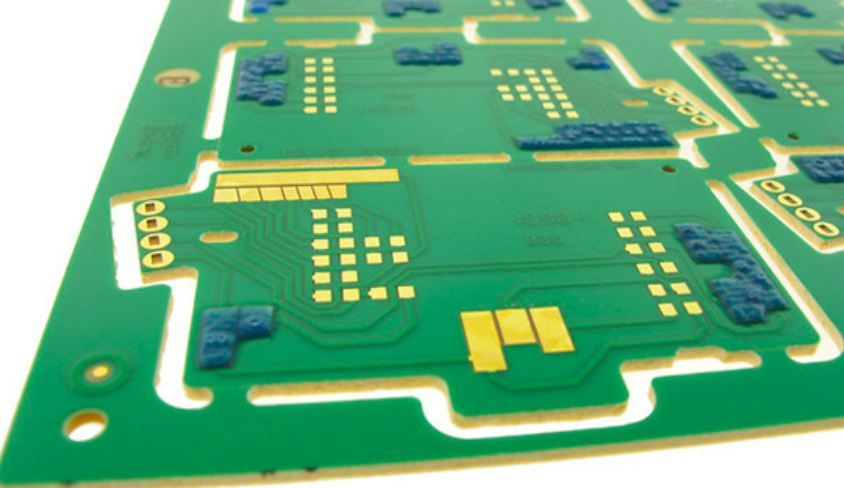

Soft and hard PCB design points

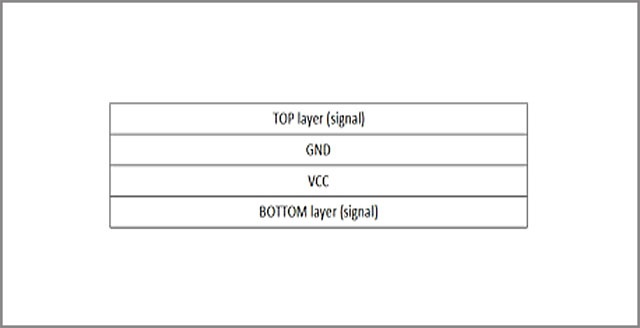

Soft and hard combined board PCB design points: 1, flexible area line design requirements, 2, dimensional stability, 3, covering film window design, 4, rigid flexible transition zone design, 5, flexible zone design with air-gap requirements